Lithium transitional metal oxide and preparation method and application thereof

A technology of transition metals and oxides, applied in electrical components, battery electrodes, circuits, etc., to achieve the effect of simple operation, strong universality, and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) 4mmol Ni(Ac) 2 4H 2 O and 12mmol Mn(Ac) 2 2H 2 O was dissolved in 100mL water to make solution A; 16mmol terephthalic acid and 36mmol NaOH were dissolved in 50mL water to make solution B; under stirring condition, solution A was slowly added dropwise to solution B, stirred at room temperature for 8h, and aged 12h;

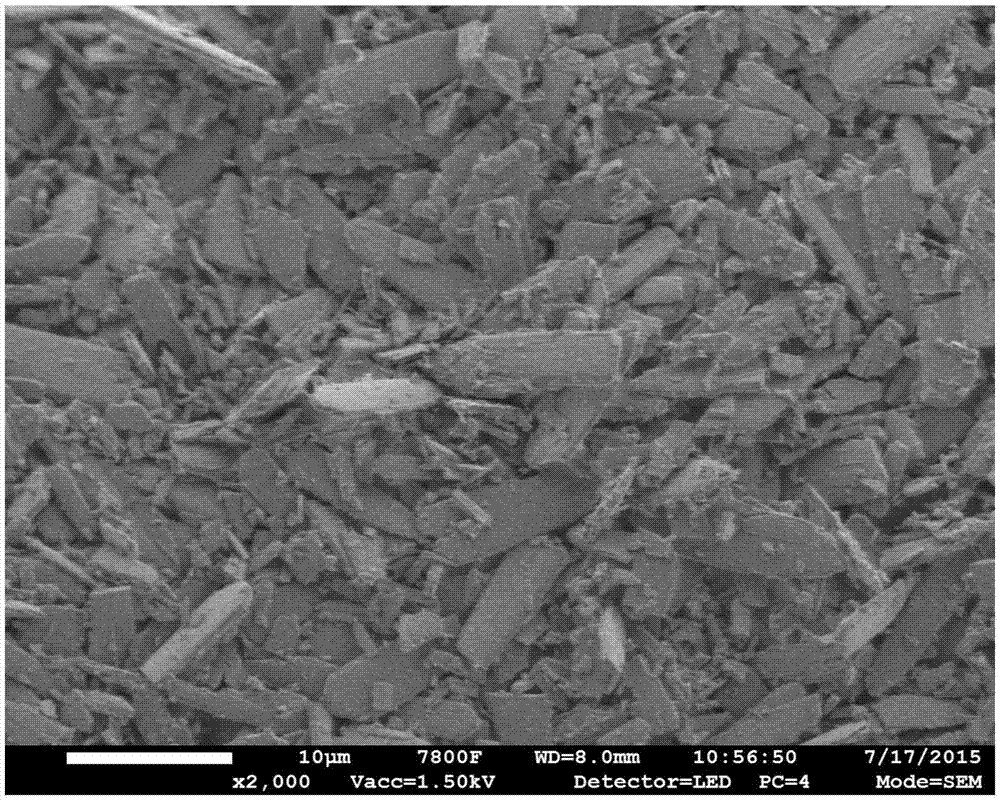

[0047] (2) After centrifugation, washing, and drying, a khaki-yellow precursor is obtained. Under a scanning electron microscope, as attached figure 1 The nickel-manganese-organic ligand polymer shown has a micron-scale long flake shape with a width of about 2-4um and a length of 6-8m. The precursor was calcined at 450° C. in an air atmosphere for 5 hours to obtain nickel manganese oxide.

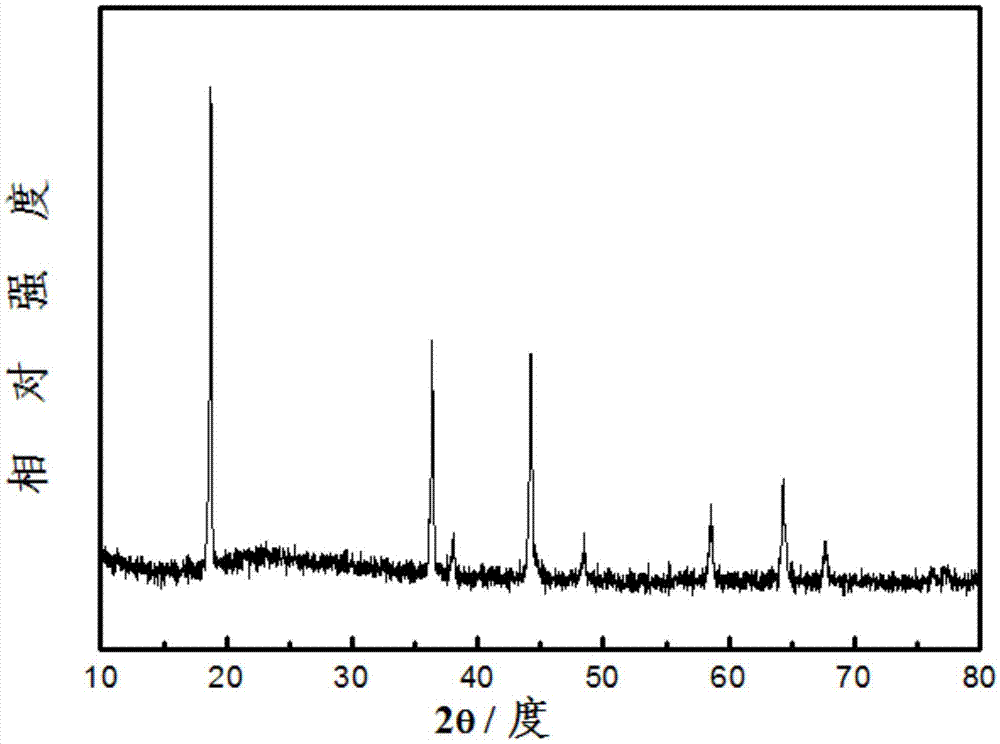

[0048] (3) through inductively coupled plasma emission spectrometer (ICP), the nickel and manganese molar ratio in the nickel-manganese oxide is 5.5:1, and the nickel-manganese oxide and excessive 10% LiAc·2H 2 O (the molar ratio of Ni+Mn to Li is 2:1) is disper...

Embodiment 2

[0054] The preparation process of Example 1 is adopted, except that the coordination regulator PVP is added to the solution B. LiNi prepared by X-ray diffraction 0.4 mn 1.6 o 3.98 It has a spinel structure and a nanosheet morphology of 300nm*60nm. Using the same pole piece fabrication method as in Example 1, the material exhibits excellent electrochemical performance.

Embodiment 3

[0056] (1) 4mmol Ni(Ac) 2 4H 2 O and 12mmol Mn(Ac) 2 2H 2 O was dissolved in 100mL ethanol to make solution A; 16mmol terephthalic acid and 36mmol NaOH were dissolved in 50mL water to make solution B; under stirring condition, solution A was slowly added dropwise to solution B, stirred at room temperature for 12h, and aged 48h;

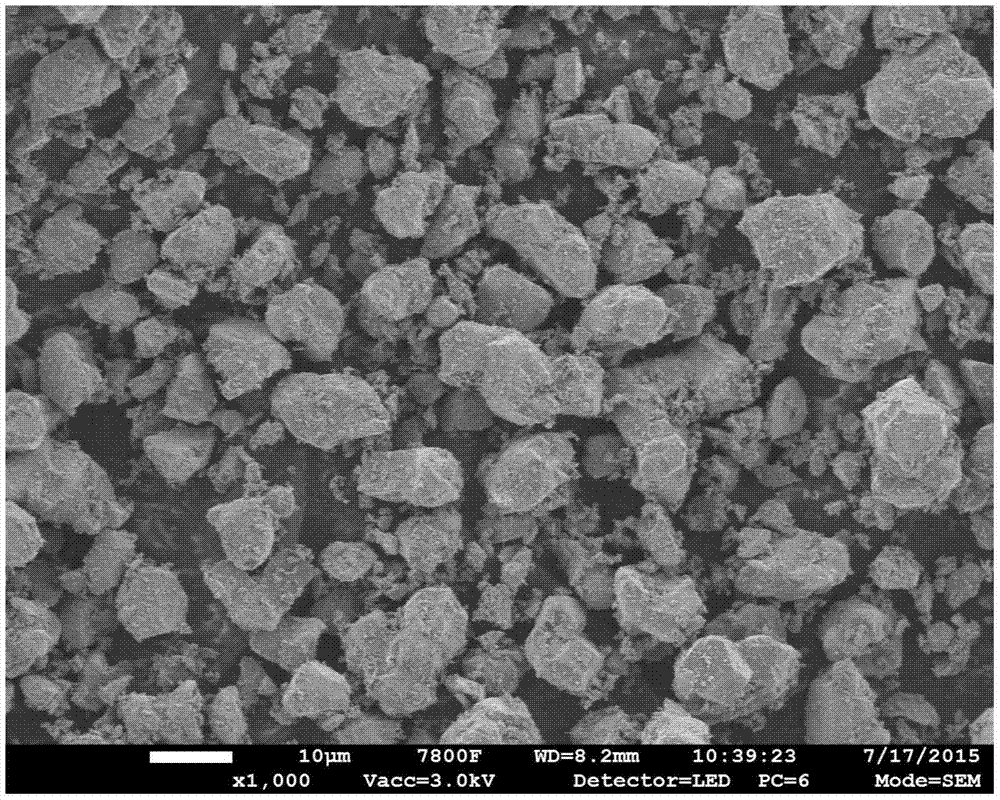

[0057] (2) After centrifugation, washing, and drying, a khaki-yellow precursor is obtained, and the scanning electron microscope photo is as attached Figure 6 As shown, the obtained nickel-manganese-organic ligand polymer precursor has a multi-level structure, and the primary structure is irregular flakes of 200nm*300nm, and these flakes are agglomerated to form spherical particles of 3-5m. The precursor was calcined in an air atmosphere at 600° C. for 3 h to obtain nickel manganese oxide.

[0058](3) through the inductively coupled plasma emission spectrometer (ICP), the nickel and manganese molar ratio in the nickel-manganese oxide is 3:1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com