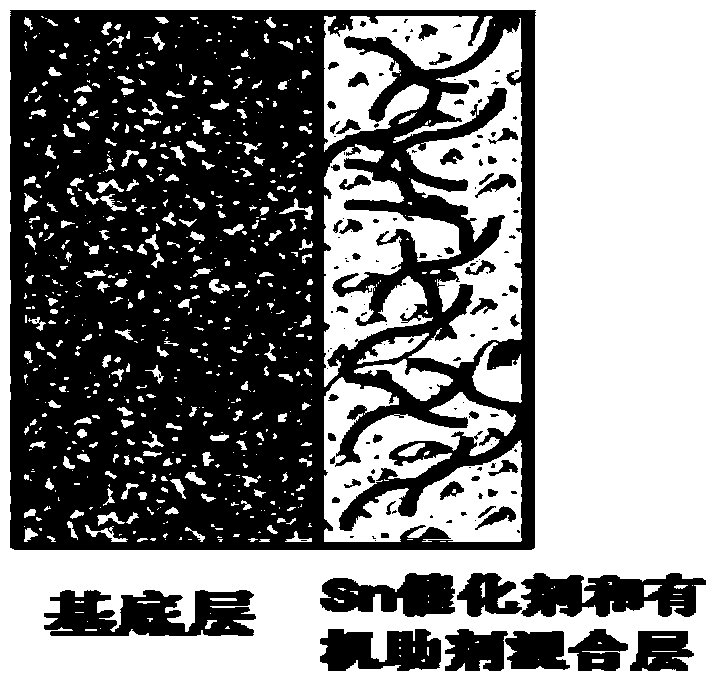

A gas diffusion electrode for electrochemical reduction of carbon dioxide and its preparation and application

A gas diffusion electrode and carbon dioxide technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of being easily decomposed and poisoned, the electrode manufacturing process is cumbersome, and the preparation method is complicated, so as to shorten the gas diffusion path and improve the effective Active area, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

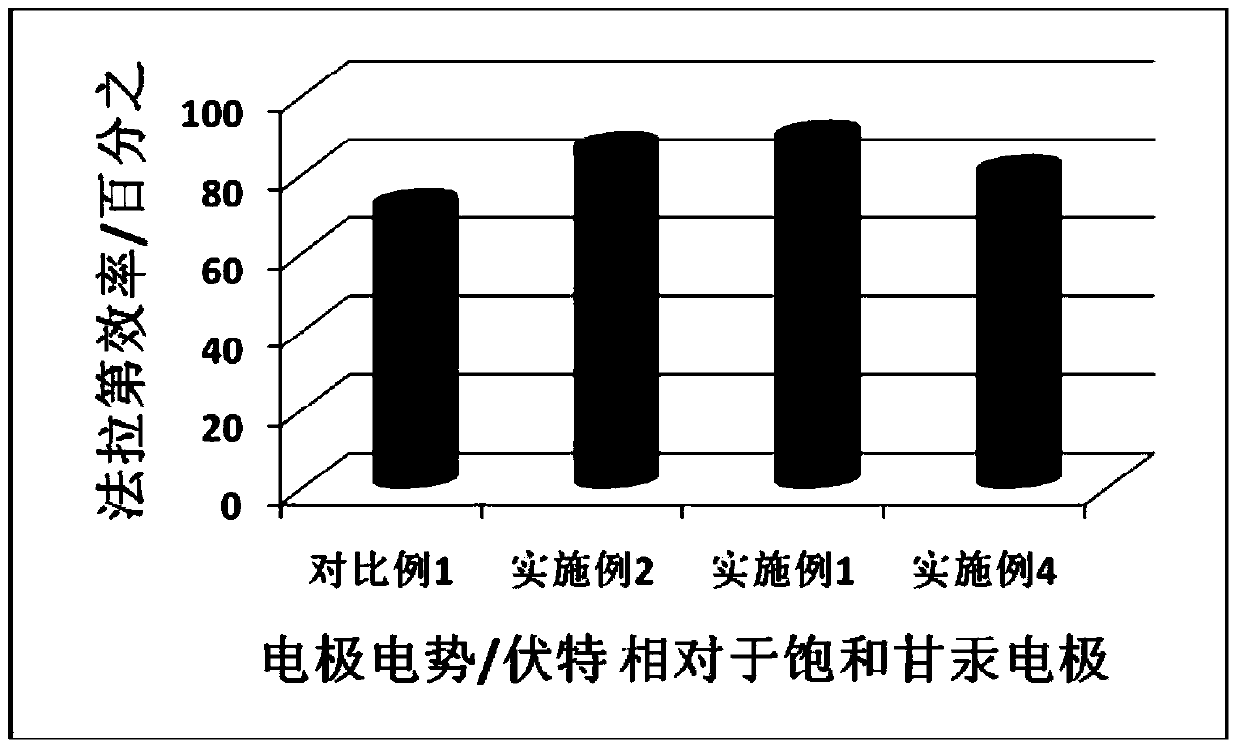

Embodiment 1

[0039] Treat with carbon paper in the air at 550°C, then degrease and clean in acetone;

[0040] Obtained by electrochemical tin plating on the surface of the above-mentioned substrate by a constant current method; in the process of electrochemical tin plating, the plating solution has a concentration of 30g / L sodium stannate Na 2 SnO 3 ·3H 2 O solution, 15g / LNaOH solution and 5g / L buffer solution mixture; the constant current is -60mA / cm 2 , the tinning time is 10000s; dissolve phenol in the mixed solvent of DMF and THF, and stir at a temperature of 25-50 degrees Celsius until the organic additives are completely dissolved to form a solution with a mass concentration of 10%; the mass content of THF in the mixed solvent 20%; by spraying, the above-mentioned organic additive solution is sprayed onto the surface of the obtained Sn catalyst; the electrode prepared in the above step 4) is taken out and dried at room temperature, and then dried in a vacuum oven at 80 degrees Cels...

Embodiment 2

[0042] Treat with carbon paper in the air at 550°C, then degrease and clean in acetone;

[0043] Obtained by electrochemical tin plating on the surface of the above-mentioned substrate by a constant current method; in the process of electrochemical tin plating, the plating solution has a concentration of 30g / L sodium stannate Na 2 SnO 3 ·3H 2 O solution, 15g / L KOH solution and 5g / L buffer solution mixture; the constant current is -40mA / cm 2 , the tinning time is 10000s; dissolve phenol in the mixed solvent of DMF and THF, and stir at a temperature of 25-50 degrees Celsius until the organic additives are completely dissolved to form a solution with a mass concentration of 20%; the mass content of THF in the mixed solvent 30%; Utilize the mode of spraying, the above-mentioned organic auxiliary agent solution is sprayed on the Sn catalyst surface that obtains; The electrode that above-mentioned step 4) is prepared is taken out and dried in room temperature, after drying in vacu...

Embodiment 3

[0045] Treat with carbon paper in air at 450°C, then degrease and clean in acetone;

[0046] Obtained by electrochemical tin plating on the surface of the above substrate by a constant voltage method; in the process of electrochemical tin plating, the plating solution has a concentration of 30g / L sodium stannate Na 2 SnO 3 ·3H 2 O solution, 15g / L NaOH solution and 5g / L buffer solution mixture; the constant voltage is -1.2V, and the tin plating time is 10000s; polyacrylonitrile is dissolved in DMF and THF mixed solvent, and the temperature is 25-50 Stir until the organic auxiliary agent is completely dissolved in Celsius to form a solution with a mass concentration of 10%; the mass content of THF in the mixed solvent is 20%; the above-mentioned organic auxiliary agent solution is sprayed onto the surface of the obtained Sn catalyst by spraying; The electrode prepared in the above step 4) was taken out and dried at room temperature, and then dried in a vacuum oven at 80 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com