Hemostatic anti-adhesive membrane and preparation method thereof

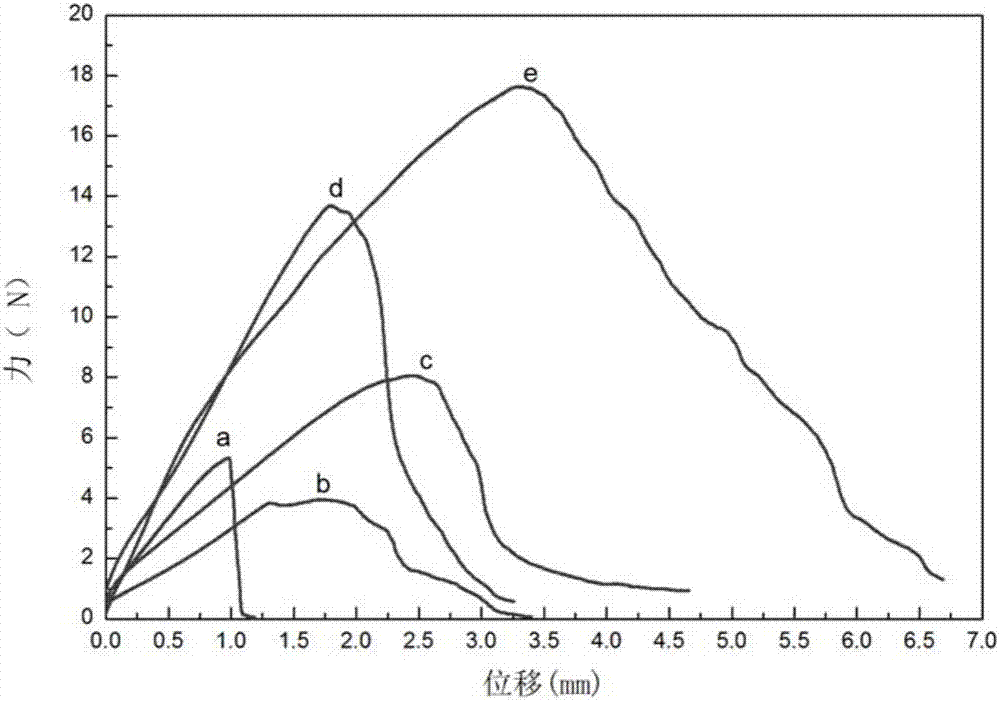

An anti-adhesion film and composite fiber film technology, applied in the field of medical devices, can solve the problems of poor softness and adherence performance of chitosan electrospinning film, affecting the use performance of final products, poor mechanical properties of fiber film, etc. Achieve the effect of excellent biocompatibility, high toughness and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a hemostatic anti-adhesion film, the steps are as follows:

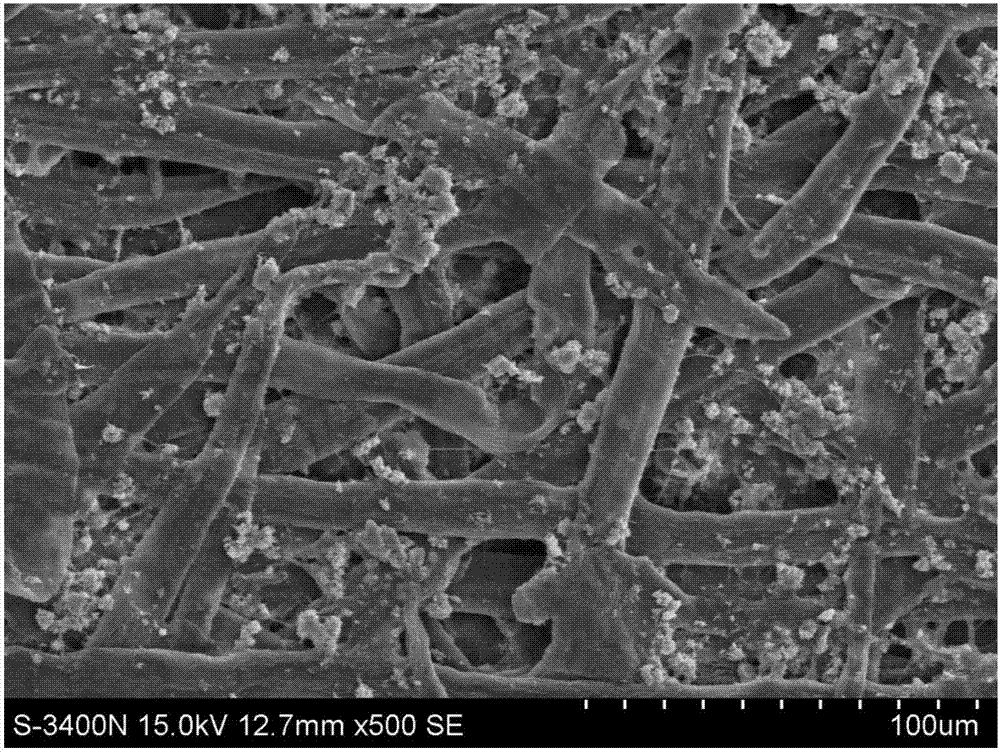

[0040](1) be 150,000 by weight-average molecular weight, the chitosan that deacetylation degree is 98% is dissolved in the acetic acid aqueous solution of concentration 90wt%, stirs to obtain uniform electrospinning solution, the concentration of chitosan in the electrospinning solution The electrospinning solution is 10wt%, and the chitosan fiber membrane is obtained by electrospinning. The spinning conditions of the electrospinning are: the voltage is 40kV, the distance from the spinneret to the collecting plate is 15cm, and the spinneret electrospinning The flow rate of silk solution is 2.5mL / h;

[0041] (2) vacuum drying removes the residual acid in the chitosan fiber membrane, and then the chitosan fiber membrane is immersed in the concentration of -5 ℃ in the sodium carboxymethyl cellulose aqueous solution of 0.01wt% to obtain the composite fiber membrane for 30min, wherein , the...

Embodiment 2

[0052] A preparation method of a hemostatic anti-adhesion film, the steps are as follows:

[0053] (1) be 10,000 by weight-average molecular weight, the chitosan that deacetylation degree is 70% is dissolved in the acetic acid aqueous solution that concentration is 95wt%, stirs to obtain uniform electrospinning solution, the amount of chitosan in electrospinning solution The concentration is 15wt%. The electrospinning solution also contains polyoxyethylene, and the weight ratio of polyoxyethylene to chitosan is 1:5. The electrospinning solution is electrospun to obtain a chitosan fiber film. Electrospinning The spinning conditions of the silk are: the voltage is 15kV, the distance from the spinneret to the collecting plate is 5cm, and the flow rate of the spinneret electrospinning solution is 0.5mL / h;

[0054] (2) Vacuum drying removes the residual acid in the chitosan fiber film, then the chitosan fiber film is immersed in the concentration of 5 DEG C in 1wt% sodium hyalurona...

Embodiment 3

[0065] A preparation method of a hemostatic anti-adhesion film, the steps are as follows:

[0066] (1) be 450,000 by weight-average molecular weight, the chitosan that deacetylation degree is 80% is dissolved in the acetic acid aqueous solution that concentration is 50wt%, stirs to obtain uniform electrospinning solution, the amount of chitosan in the electrospinning solution Concentration is 3wt%, also contains polyvinyl alcohol in the electrospinning solution, the weight ratio of polyvinyl alcohol and chitosan is 1:2, the chitosan fiber membrane is made by electrospinning solution by electrospinning, electrospinning The spinning conditions of the silk are: the voltage is 30kV, the distance from the spinneret to the collecting plate is 10cm, and the flow rate of the spinneret electrospinning solution is 2mL / h;

[0067] (2) Vacuum drying removes the residual acid in the chitosan fiber membrane, and then the chitosan fiber membrane is immersed in a 5wt% sodium alginate aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com