Nanometer magnesium hydroxide and preparation method thereof

A technology of nano-magnesium hydroxide and oxidation reaction, applied in the direction of magnesium hydroxide, nanotechnology, etc., can solve the problems of high cost and difficult large-scale application of magnesium/air batteries, achieve good uniformity, high purity, and enhance economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

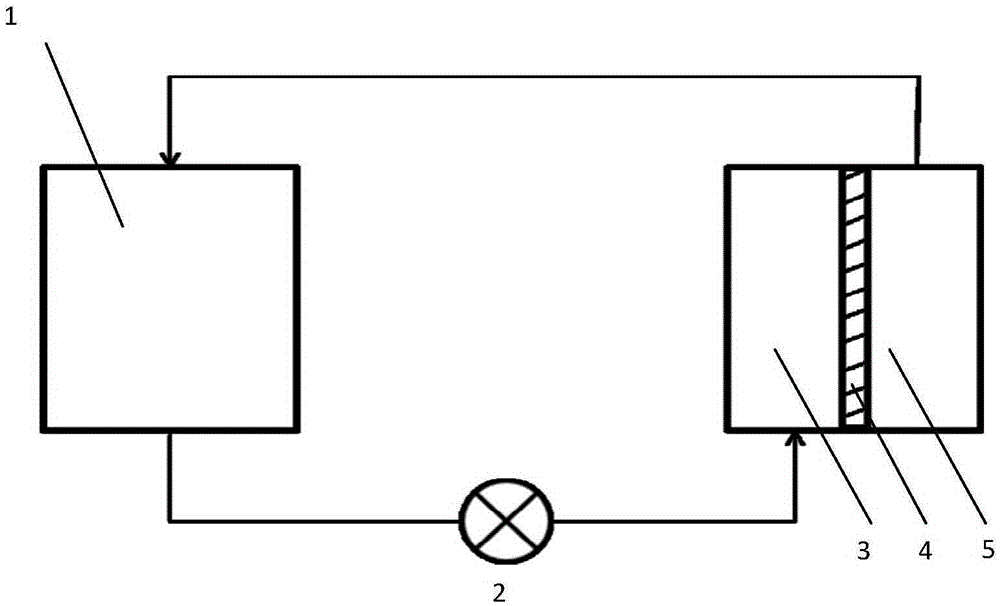

[0030] The magnesium / air battery uses 99.9% high-purity magnesium as the anode, and the cathode includes a catalytic layer, a hydrophobic diffusion layer and a current collector cathode, and the electrode area is 32cm 2 . The cathode catalytic layer is MnO with a mass loading of 60% 2 / C is the catalyst, PTFE is the hydrophobic agent, and the catalyst loading in the catalytic layer is 8mg cm -2 , the mass content of PTFE is 20%; the hydrophobic diffusion layer is graphitized carbon fiber felt after the hydrophobic treatment of PTFE emulsion, and the thickness is 3mm; PTFE accounts for 70% of the total mass of the hydrophobic diffusion layer; the current collecting layer is nickel foam. The electrolyte solution is sodium chloride aqueous solution with a mass fraction of 10%.

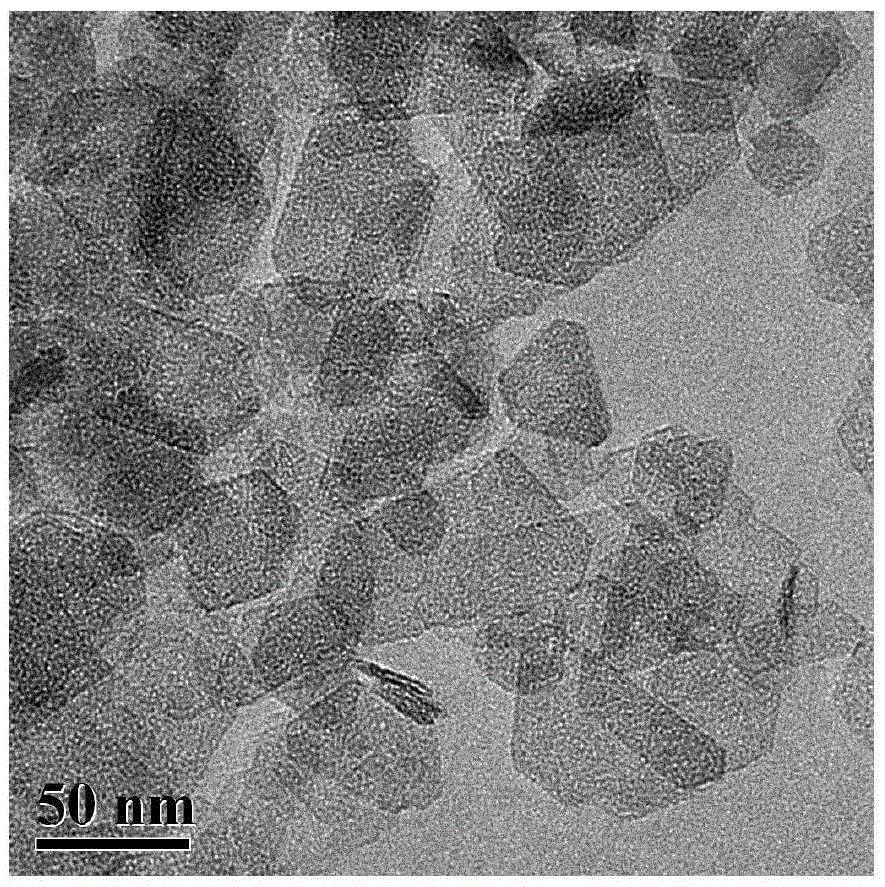

[0031] Magnesium / air battery at 0.5mA / cm 2 Discharge with a current density of 25°C. During the discharge process, a circulation pump is used to discharge the electrolyte and products to the product / el...

Embodiment 2

[0033] Using the magnesium / air battery described in Example 1 to prepare nano-magnesium hydroxide.

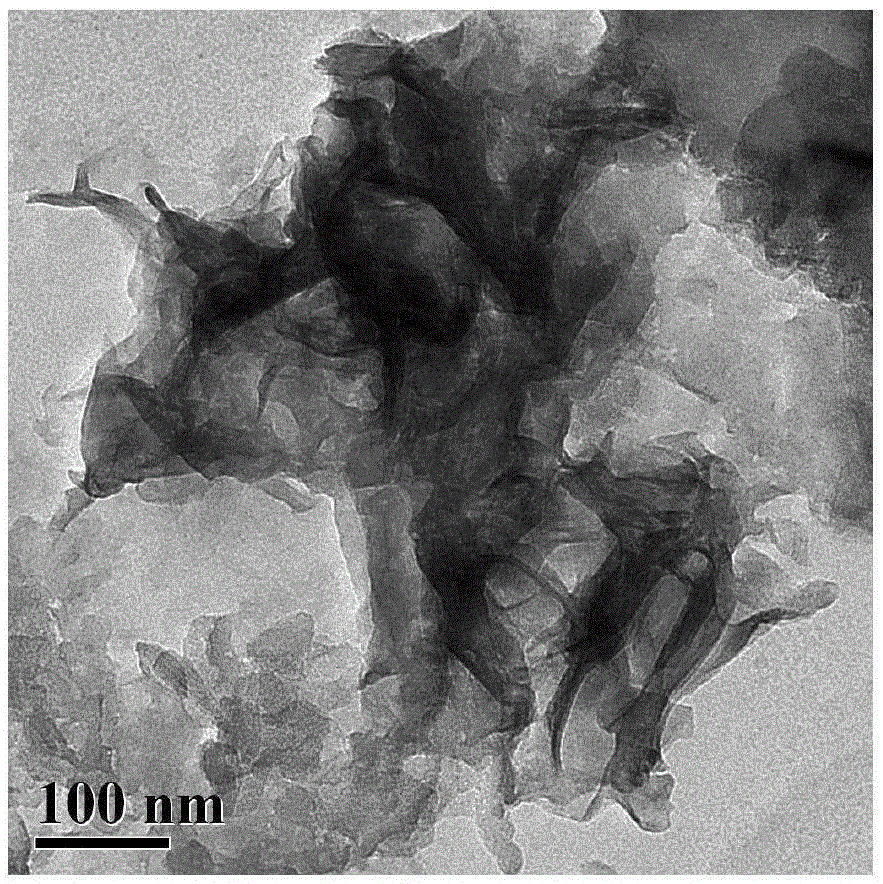

[0034] Magnesium / air battery at 30mA / cm 2 Discharge with a current density of 50°C. During the discharge process, a circulation pump is used to discharge the electrolyte and products to the product / electrolyte storage tank. After the product is filtered through a 200-mesh nylon filter, a slurry-like magnesium hydroxide product is obtained. After the product was taken out from the liquid storage tank, it was rinsed with deionized water and filtered three times with a suction filter, and then dried in a drying oven at a temperature of 60°C for 12 hours to obtain image 3 The shown nano-magnesium hydroxide particles have a particle size of about 100-500nm and a flower-like structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com