Powdery polycarboxylic acid type slump retaining agent and preparation method thereof

A technology of polycarboxylate and slump-retaining agent, which is applied in the field of concrete admixture, can solve problems such as high temperature and complex process, and achieve the effects of unaffected performance, no solvent poisoning, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

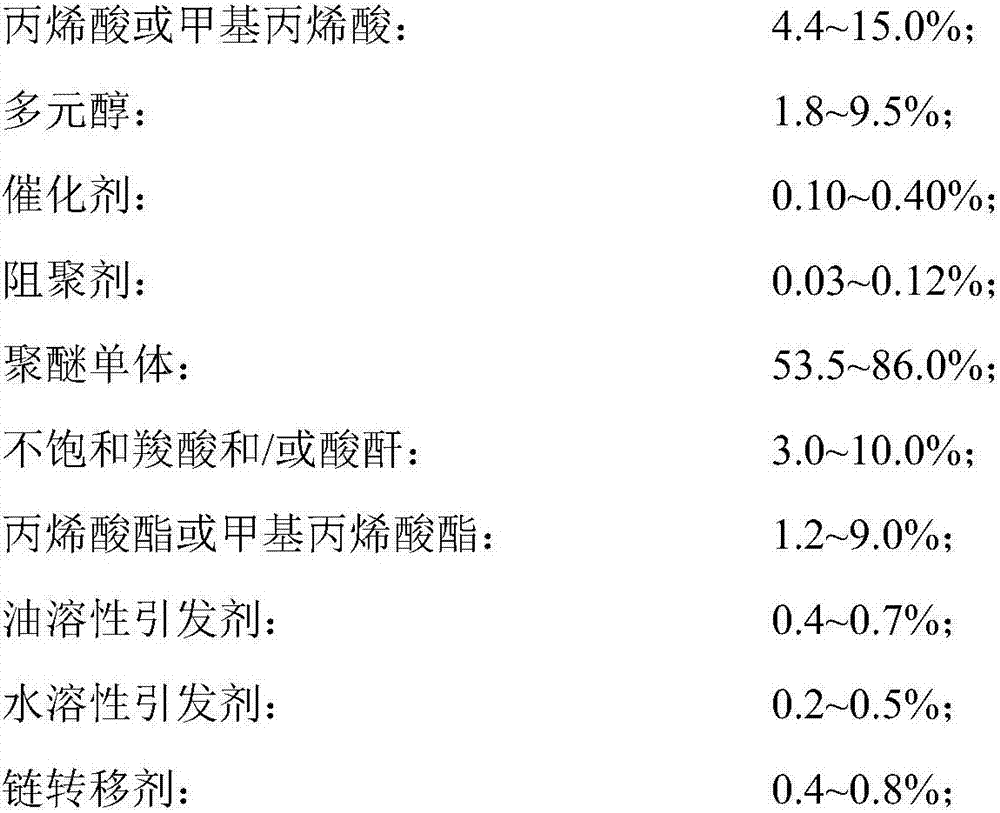

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of ester monomers: add 312.8kg methacrylic acid, 94.0kg ethylene glycol, 8.1kg sulfamic acid to the reaction kettle equipped with thermometer, stirring paddle, constant flow pump, condenser and water separator and 2.0kg of hydroquinone, heat up to 110-120°C under stirring, stir and reflux for 3-3.5 hours, separate the water layer with a water separator and lower the temperature to 60-70°C;

[0035] (2) Preparation of molten polycarboxylic acid series slump-retaining agent: add 4168kg isopentenol polyoxyethylene ether (molecular weight 2400), stir and melt, then add 29.2kg benzoyl peroxide and stir to dissolve; then 19.5kg over Sodium sulfate, 38.9kg of octyl thioglycolate, 86.8kg of ethyl acrylate and 187.6kg of acrylic acid were mixed into a mixed solution, which was dripped with a constant-flow pump within 3.5-4 hours; Stir 53.1kg powder alkali evenly;

[0036] (3) Preparation of powdered polycarboxylate-based slump-retaining agent: the melted product...

Embodiment 2

[0038] (1) Preparation of ester monomers: add 417.8kg methacrylic acid, 125.5kg ethylene glycol, 10.9kg sulfamic acid to the reaction kettle equipped with thermometer, stirring paddle, constant flow pump, condenser and water separator and 2.7kg of hydroquinone, heat up to 110-120°C under stirring, stir and reflux for 3-3.5 hours, separate the water layer with a water separator and cool down to 60-70°C;

[0039] (2) Preparation of molten polycarboxylic acid series slump-retaining agent: add 3712kg isopentenol polyoxyethylene polyoxypropylene ether (molecular weight 1600), stir and melt, then add 29.0kg azobisisoheptanonitrile and stir to dissolve; then Mix 19.2kg of ammonium persulfate, 33.9kg of butanethiol, 269.1kg of hydroxyethyl acrylate and 299.2kg of methacrylic acid into a mixed solution, and drop it with a constant-current pump within 2.5 to 3 hours; continue to keep warm for 4 hours after dropping, Add 80.9kg powder alkali and stir evenly;

[0040] (3) Preparation of ...

Embodiment 3

[0042] (1) Preparation of ester monomers: add 707.0kg methacrylic acid, 212.4kg ethylene glycol, 18.4kg sulfamic acid to the reaction kettle equipped with thermometer, stirring paddle, constant flow pump, condenser and water separator and 4.6kg of hydroquinone, heated up to 100-110°C under stirring, stirred and refluxed for 4-5 hours, separated the water layer with a water separator and lowered the temperature to 60-70°C;

[0043] (2) Preparation of molten polycarboxylate slump-retaining agent: add 3140kg isopentenol polyoxyethylene ether (molecular weight 1200), stir and melt, then add 384.8kg maleic anhydride and 33.5kg benzoyl peroxide and stir to dissolve ; Then 14.4kg of sodium persulfate, 38.5kg of 3-mercaptopropionate octyl and 340.3kg of hydroxyethyl methacrylate are formulated into a mixed solution, and are dripped with a constant flow pump within 3 hours; Add 106.1kg powder alkali and stir evenly;

[0044] (3) Preparation of powdery polycarboxylate slump retaining a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com