Preparation of superparamagnetic mesoporous molecularly imprinted polymer of core-shell structure and application as solid phase extractant

A technology of magnetic molecular imprinting and core-shell structure, applied in alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of reduced binding force, mass transfer hindrance, time and labor waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

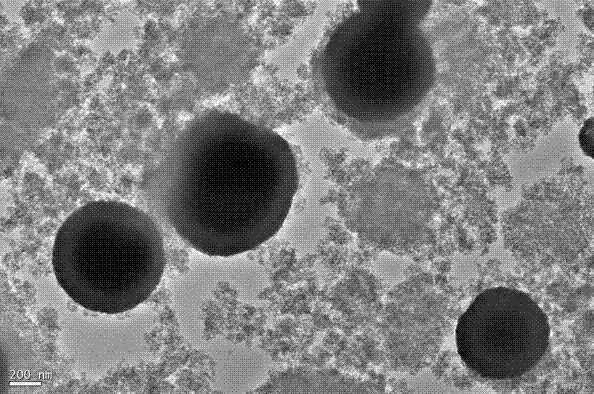

[0056] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0057] Add 0.86g FeCl to 30mL ethylene glycol 3 ·6H 2 O and 2.16g of sodium acetate, magnetically stirred to a uniform yellow solution, transferred to a reaction kettle, placed in an oven at 200°C for a constant temperature reaction for 12 hours, taken out and cooled to room temperature, and washed three times with ethanol and secondary water respectively to obtain Fe 3 o 4 The magnetic nanoparticles were dried in an oven at 60°C, and then ground for later use.

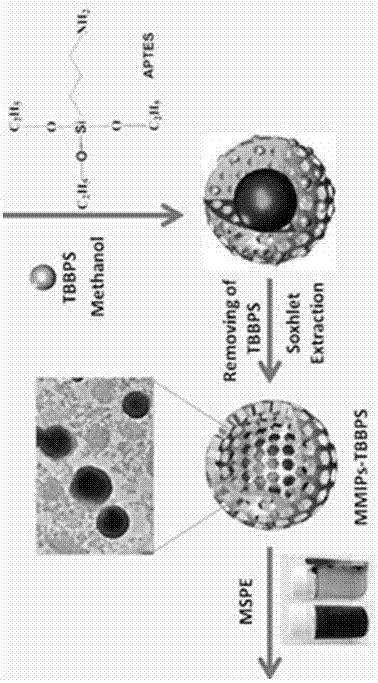

[0058] (2) Preparation of magnetically imprinted polymer MMIPs-TBBPS

[0059] Dissolve 0.5mmol (0.283g) of tetrabromobisphenol S and 2mLAPTES (3-aminopropyltriethoxysilane) into 10mL of anhydrous methanol solution and keep at room temperature for 2h to obtain solution I;

[0060] Accurately weigh 0.2gFe 3 o 4 Disperse the nanoparticles in 60mL of methanol and 10mL of distilled water, sonicate until completely dissolved; then add 4mLTEOS, 1mL of ammon...

Embodiment 2

[0065] (1) Fe 3 o 4 Preparation of magnetic nanoparticles: same as Example 1;

[0066] (2) Preparation of magnetically imprinted polymer MMIPs-TBBPS

[0067] Dissolve 0.5mmol (0.283g) tetrabromobisphenol S and 1.9mLAPTES (3-aminopropyltriethoxysilane) in 10mL of anhydrous methanol solution, and keep at room temperature for 2h to obtain solution I;

[0068] Accurately weigh 0.17gFe 3 o 4 Disperse the nanoparticles in 60mL of methanol and 10mL of distilled water, sonicate until completely dissolved; then add 3mLTEOS, 1mL of ammonia (28%), and stir for 5min to obtain solution II;

[0069] Add solution II to the above solution I, and stir mechanically at room temperature for 1 h; after the reaction product is taken out, wash with ethanol and deionized water for 5 times, and dry at 60°C to obtain a magnetic molecularly imprinted polymer;

[0070] The magnetic molecularly imprinted polymer was placed in a Soxhlet extractor, and was eluted with a mixed solution of methanol / aceti...

Embodiment 3

[0073] (1) Fe 3 o 4 Preparation of magnetic nanoparticles: same as Example 1;

[0074] (2) Preparation of magnetically imprinted polymer MMIPs-TBBPS

[0075] Dissolve 0.5mmol (0.283g) tetrabromobisphenol S and 2.1mLAPTES (3-aminopropyltriethoxysilane) into 10mL methanol solution and keep at room temperature for 2h to obtain solution I;

[0076] Accurately weigh 0.23gFe 3 o 4 Disperse the nanoparticles in 60mL of methanol and 10mL of distilled water, sonicate until completely dissolved; then add 5mLTEOS, 1mL of ammonia water (28%), and stir for 5min to obtain solution II;

[0077] Add solution II to the above solution I, and stir mechanically at room temperature for 1 h; after the reaction product is taken out, wash with ethanol and deionized water for 5 times, and dry at 60°C to obtain a magnetic molecularly imprinted polymer;

[0078] The magnetic molecularly imprinted polymer was placed in a Soxhlet extractor, and eluted with a mixed solution of methanol / acetic acid (9:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com