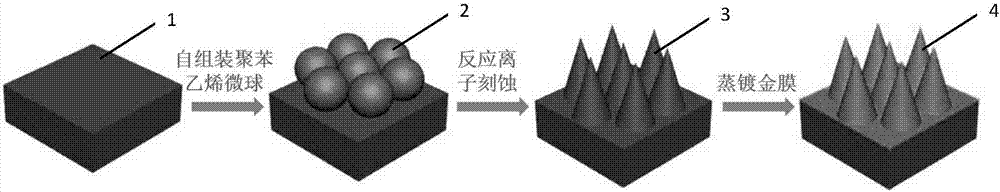

Method for improving desorption ionization efficiency by enriching analyte to metal nanocone array tip

A metal nanometer and analyte technology, applied in the field of detection, can solve the problems that are not conducive to improving the desorption and ionization efficiency of the analyte molecules, the energy utilization efficiency is not high, and the laser energy needs to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

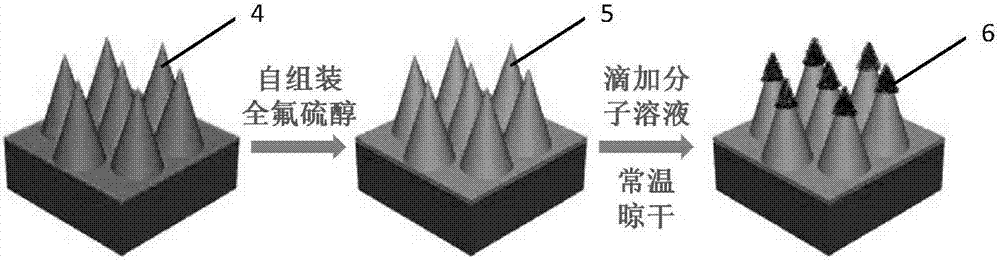

Embodiment 1

[0062] First cut the silicon wafer into 10 pieces, of which 9 pieces have a size of 1.5cm×1.5cm, and one piece has a size of 4cm×6cm, and then use acetone, chloroform, ethanol, and deionized water to ultrasonically clean each at 70W for 5 minutes. Prepare NH 3 ·H 2 O (25% aqueous solution by mass fraction): H 2 o 2 (30% aqueous solution by mass fraction): H 2 O=1:1:5 (volume ratio) mixed solution, heat it to 90°C, then immerse the cleaned silicon chip in the solution and cook for 40min. Finally, they were rinsed with deionized water and dried with nitrogen to obtain ball-raising silicon wafers (1.5 cm×1.5 cm) and volleyball silicon wafers (4 cm×6 cm).

[0063] Add 0.1 g of polystyrene microsphere powder with a diameter of 600 nm into 2 mL of a mixed solution of deionized water and ethanol at a volume ratio of 1:1, ultrasonicate for 6 hours, and mix it evenly to obtain ethanol and ethanol of polystyrene microspheres. Deionized water mixed solution. Add deionized water to ...

Embodiment 2

[0068] 2 μL of water was added dropwise to the gold film-covered silicon nanocone array and the perfluorothiol-modified gold-covered silicon nanocone array obtained in different steps of Example 1 to measure the contact angle and rolling angle.

Embodiment 3

[0070] Put the gold-covered silicon nanocone arrays and perfluorothiol-modified gold-covered silicon nanocone arrays obtained in different steps in Example 1 into the instrument for spectral testing. This test was performed in Shanghai Fuxiang R1-A-UV series Tested on a spectrometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Tip diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com