A kind of composite magnesia-carbon brick and preparation method thereof

A composite magnesia-carbon brick and binder technology, which is applied in the field of refractory materials, can solve the problems of difficult production, high price, and high manufacturing cost, and achieve the effects of high refractoriness, low solubility, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

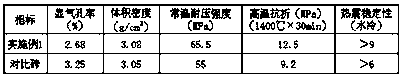

Examples

Embodiment 1

[0025] The method of using composite additives to strengthen the preparation of magnesia carbon bricks is as follows.

[0026] Step 1. Prepare aggregate: 45% of regenerated magnesia-carbon bricks with a particle size of 1-10mm, 5% of fused magnesia with a particle size of 3-5mm, 10% of fused magnesia with a particle size of 1-3mm, and fused magnesia with a particle size of 0.1-1mm Magnesia 15%, mixed according to the required ratio, set aside.

[0027] Step 2. Preparation of premixed powder: fused magnesia fine powder with a particle size of 0.1 μm-88 μm, the percentage by weight is 10%; Bonite fine powder (calcium hexaaluminate (CA6)) 4%, metal Aluminum fiber 0.5%, magnesium-forsterite synthetic sand fine powder 2% synthetic sand fine powder; asphalt powder 0.5%, metal silicon powder 1.5%, metal aluminum-magnesium alloy powder 1.5%, pre-mixed in proportion for later use.

[0028] Step 3, mixing: add the aggregate and premixed powder in step 1 and step 2, the particle size is...

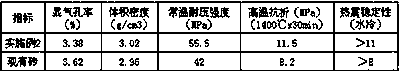

Embodiment 2

[0038] A method for enhancing the preparation of magnesia carbon bricks with composite additives.

[0039] Step 1. Prepare aggregate: 50% of regenerated magnesia-carbon bricks with a particle size of 1-10mm, 5% of fused magnesia with a particle size of 3-5mm, 5% of fused magnesia with a particle size of 1-3mm, and fused magnesia with a particle size of 0.1-1mm 10% magnesia, mixed according to the required ratio, set aside.

[0040] Step 2. Preparation of pre-mixed powder: fused magnesia fine powder with a particle size of 0.1 μm-88 μm, the weight percentage is 9%; Bonite fine powder (calcium hexaaluminate (CA6)) 3%, metal Aluminum fiber 0.5%, magnesium-forsterite synthetic sand fine powder 2% synthetic sand fine powder; asphalt powder 1%, metal silicon powder 1%, metal aluminum-magnesium alloy powder 1.5%, pre-mix according to the proportion, and set aside.

[0041] Step 3, mixing: Add the aggregate and mixed powder in step 1 and step 2, 8% of graphite with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com