Synthesis method of polyamide polyamine resin

A technology of polyamide polyamine resin and synthesis method, which is applied in coating, paper coating, paper and other directions, can solve the problems of fluctuation of water content of paper web, insufficient softness of finished paper, degraded quality of finished paper, etc., and achieve a good foundation. Paper quality, improved properties, reduced corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

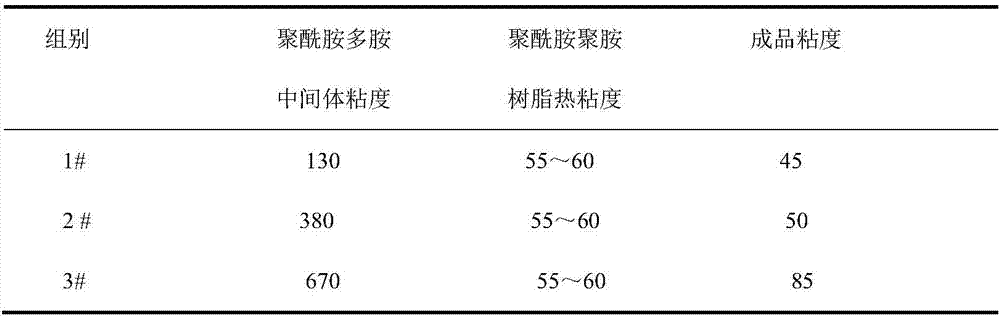

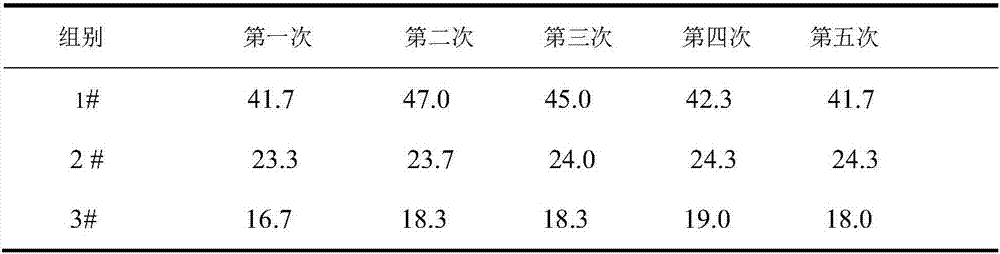

[0028] Weigh 146 grams of adipic acid (1.0 mol) and 360 grams of deionized water into the four-necked flask, stir to form a slurry, vacuumize and feed nitrogen, then add 52.6 grams of diethylenetriamine (0.51mol), 60.2 grams of N -2-Aminoethyl-1,3-propanediamine (0.50mol), heat up to 180°C by electric heating, keep warm for 2 hours, collect about 265 grams of water released during the reaction, add 220 grams of water to distill out the polyamide intermediate body, its index is that the solid content is 50%, the viscosity is 130cps, and the pH is 10.8.

[0029] 100 g (0.227 mol) of the above-mentioned polyamide aqueous solution, 26.4 g (0.227 mol) of N,N-tetramethylethylenediamine, 125 g of deionized water, and 0.1 g of potassium carbonate were heated to 38° C. during stirring, and dripped Add quaternized cross-linking agent, including 16.5 g (0.114 mol) of epichlorohydrin, 10.5 g (0.114 mol) of dichloroethyl ether, add dropwise for 1 h, then raise the temperature to 63 ° C, ke...

Embodiment 2

[0031] Weigh 146 grams of adipic acid (1.0 mol) and 250 grams of deionized water into a four-necked flask, stir to form a slurry, vacuumize and feed nitrogen, then add 62.8 grams of diethylenetriamine (0.61 mol), 48.1 grams of N -2-Aminoethyl-1,3-propanediamine (0.40mol), heat up to 175°C by electric heating, keep it warm for 2.5h, collect about 285 grams of water released during the reaction, add 220 grams of water to distill out the polyamide Intermediate, its index is that solid content is 50%, viscosity is 380cps, and pH is 10.5.

[0032] 100 grams (0.227 mol) of the above-mentioned polyamide aqueous solution, 14.2 grams (0.122 mol) of N,N-tetramethylethylenediamine, 140 grams of deionized water, and 0.1 g of potassium carbonate were heated to 32 ° C during the stirring process, and dripped Add quaternized cross-linking agent, including 13.7 g (0.141 mol) of epichlorohydrin, 14.0 g (0.098 mol) of dichloroethyl ether, add dropwise for 1 h, then raise the temperature to 55 °...

Embodiment 3

[0034] Weigh 146 grams of adipic acid (1.0 mol) and 120 grams of deionized water into a four-necked flask, stir to form a slurry, vacuumize and feed nitrogen, then add 42.5 grams of diethylenetriamine (0.41mol), 77.0 grams of N -2-Aminoethyl-1,3-propanediamine (0.60mol), heat up to 160°C by electric heating, keep it warm for 3 hours, collect about 236 grams of water released during the reaction, add 225 grams of water to distill out the polyamide intermediate Body, its index is that the solid content is 50%, the viscosity is 670cps, and the pH is 9.7.

[0035] 100 g (0.227 mol) of the above-mentioned polyamide aqueous solution, 45.2 g (0.390 mol) of N,N-tetramethylethylenediamine, 130 g of deionized water, and 0.08 g of sodium carbonate were heated to 45° C. during stirring, and dripped Add quaternized cross-linking agent, including 14.7 grams (0.160 mol) of epichlorohydrin, 39 g (0.275 mol) of dichloroethyl ether, dropwise for 1 hour, then raise the temperature to 65°C, keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com