Agricultural film and preparation method thereof

A technology of agricultural film and polyethylene film, which is applied in the field of agricultural film and its preparation, can solve the problems of difficult process, reduce the efficiency of functional materials, and high cost, and achieve significant economic benefits, facilitate rapid promotion, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

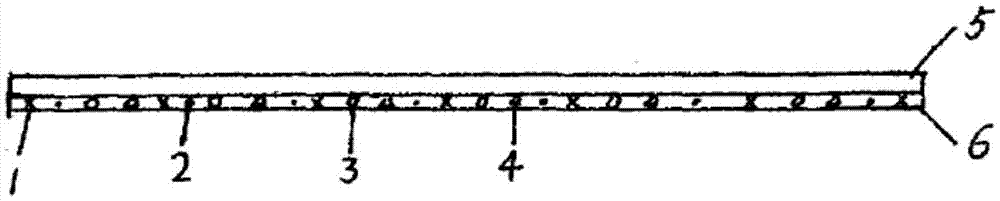

Image

Examples

Embodiment Construction

[0017] 1. Polyethylene emulsion 100g, add urea 1g, potassium dihydrogen phosphate 1g, magnesium sulfate 0.05g, ferrous sulfate 0.025g, zinc sulfate 0.01g, boric acid 0.05g, copper sulfate 0.01g, ammonium molybdate 0.005g and mix evenly. Spread the above mixed solution on a polyethylene mulch of 1 square meter, dry it at room temperature or blow it with hot air to form a film, and then it becomes a mulch film with fertilizer function.

[0018] 2. Add 100g of polyethylene emulsion, add 0.8g of promethazine, 0.1g of micro-fertilizer and stir evenly, then apply the above mixed solution on 1 square meter of polyethylene film, dry it at room temperature or with hot air to form a film, and it will become Mulch with grass and micro-fertilizer function.

[0019] 3. Add 100g of oxidized polyethylene emulsion, add 2g of vanilla, add 0.5g of carbon black, add 0.1g of fertilizer and mix evenly. Then smear it on 1 square meter polyethylene mulch, and dry it at room temperature or hot air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com