Brewing technology of red meat dragon fruit sweet type fruit wine

A red-flesh dragon fruit and fruit-sweet type technology is applied in the field of brewing technology of red-flesh dragon fruit sweet-type fruit wine, which can solve problems affecting the sales and shelf life of pitaya wine, imperfect processing technology of dragon fruit wine, unstable color, etc., and achieve Improve the juice yield, maintain the color, and promote the effect of maintaining the chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

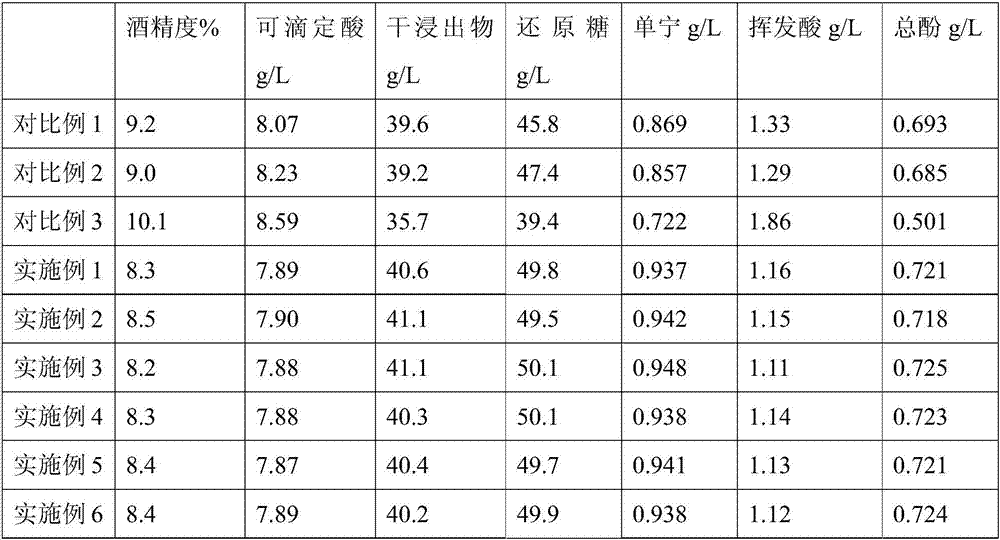

Examples

Embodiment 1

[0034] 1. Preliminary preparation:

[0035] Preparation of the syrup: in parts by weight, after stirring 100 parts of white granulated sugar and 80 parts of deionized water evenly, boil in a pot over low heat until the viscosity is 450Pa. s pale yellow viscous liquid, add 15 parts of lychee honey when the temperature is lowered to 35°C, and stir evenly to obtain syrup.

[0036] The above-mentioned pre-prepared material is used in the brewing process of the following red-fleshed pitaya sweet fruit wine.

[0037] 2. a brewing process of red-fleshed pitaya sweet fruit wine, comprising the following steps:

[0038] (1) Pre-treatment: After peeling and dicing the red-fleshed dragon fruit with no lesions, no mechanical injuries and fruit soluble solids of 12%, use a screw pump to crush and homogenate, pump into the fermenter, and then Add 10mg / L of pectinase with an enzyme activity ≥ 8000U / g, stir for 5min, let stand for 1h, add the same amount of pectinase, stir for 5min, and let...

Embodiment 2

[0044] 1. Preliminary preparation:

[0045] Preparation of the syrup: in parts by weight, after stirring 100 parts of white granulated sugar and 89 parts of deionized water evenly, boil in a pot over low heat until the viscosity is 475Pa. s pale yellow viscous liquid, add 16 parts of lychee honey when the temperature is lowered to 37°C, and stir well to obtain syrup.

[0046] The above-mentioned pre-prepared material is used in the brewing process of the following red-fleshed pitaya sweet fruit wine.

[0047] 2. a brewing process of red-fleshed pitaya sweet fruit wine, comprising the following steps:

[0048] (1) Pre-treatment: After peeling and dicing the red-fleshed dragon fruit with no scab, no mechanical injury and fruit soluble solids of 13%, use a screw pump to crush and homogenate, pump into the fermenter, and then Add 15 mg / L of pectinase with enzyme activity ≥ 8000U / g, stir for 6 minutes, let stand for 1 hour, add the same amount of pectinase, stir for 5 minutes, an...

Embodiment 3

[0054] 1. Preliminary preparation:

[0055] Preparation of the syrup: in parts by weight, after stirring 100 parts of white granulated sugar and 95 parts of deionized water evenly, boil in a pot over low heat until the viscosity is 480Pa. s pale yellow viscous liquid, add 16 parts of lychee honey when the temperature is lowered to 38°C, and stir well to obtain syrup.

[0056] The above-mentioned pre-prepared material is used in the brewing process of the following red-fleshed pitaya sweet fruit wine.

[0057] 2. a brewing process of red-fleshed pitaya sweet fruit wine, comprising the following steps:

[0058] (1) Pre-treatment: After peeling and dicing the red-fleshed dragon fruit with no lesions, no mechanical injuries and fruit soluble solids of 12.5%, use a screw pump to crush and homogenate, pump into the fermenter, and then Add 12 mg / L of pectinase with enzyme activity ≥ 8000U / g, stir for 7 minutes, let stand for 1 hour, add the same amount of pectinase, stir for 5 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com