Porous polyacrylonitrile fibers and preparation method and application thereof

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of complex operation steps, high experimental temperature requirements, long time consumption, etc., and achieves a sample preparation method. Simple, widely applicable, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve acrylonitrile-itaconic acid binary copolymer in dimethyl sulfoxide to obtain a mixed solution with a mass fraction of 20%, and add polyvinylpyrrolidone to make a spinning solution; wherein, polyvinylpyrrolidone The dosage is 20% of the mass of acrylonitrile-itaconic acid binary copolymer;

[0035] (2) Extrude the spinning solution at 50°C, enter into water with a temperature of 50°C and solidify for 300 seconds to make fibers;

[0036] (3) The fibers obtained in step (2) were vacuum-dried at 60°C for 180 minutes to obtain porous polyacrylonitrile fibers.

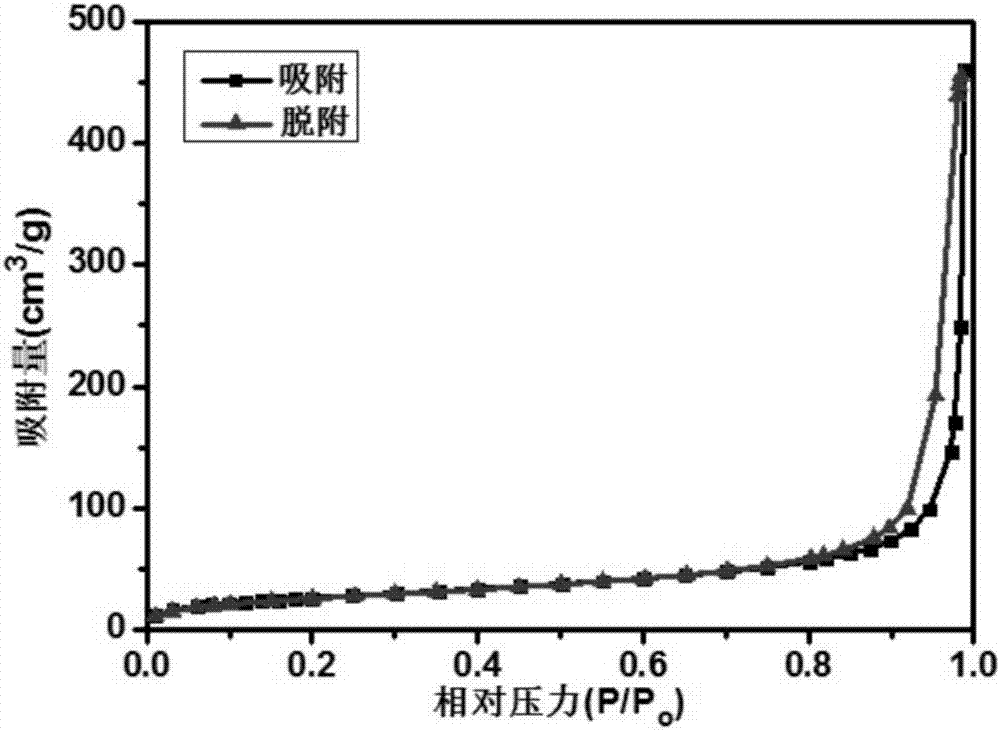

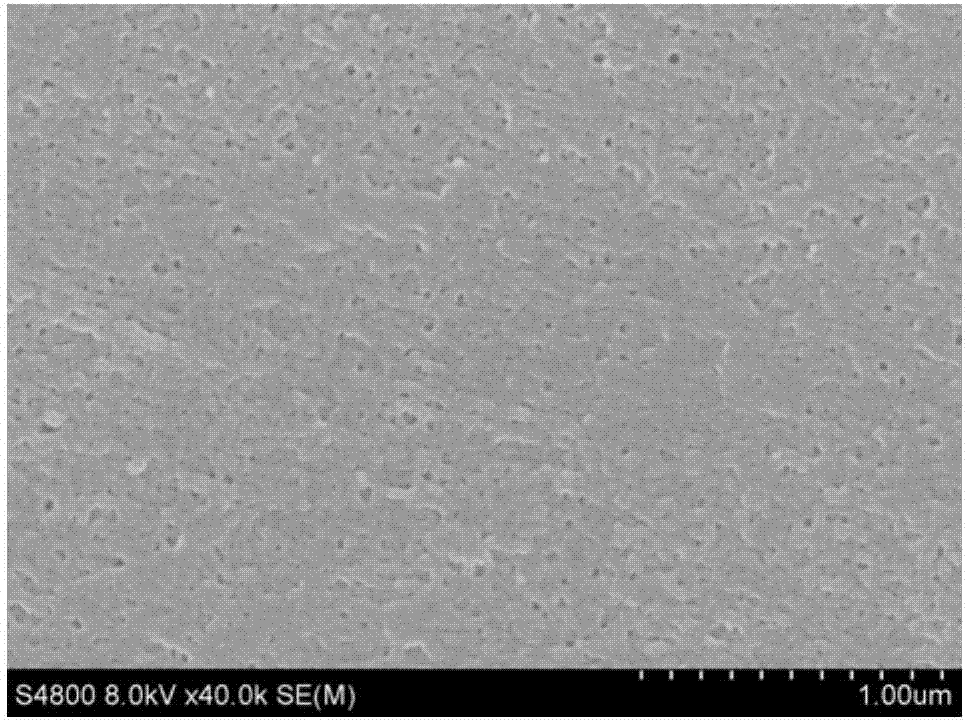

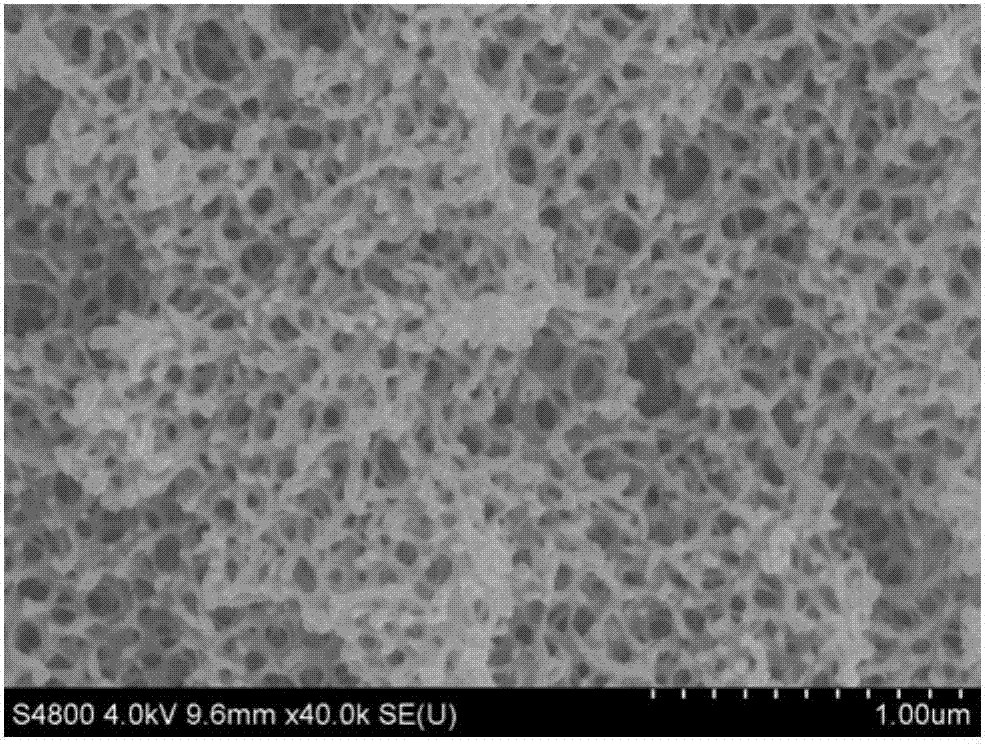

[0037] The nitrogen adsorption-desorption curve of gained porous polyacrylonitrile fiber is as follows figure 1 As shown, the specific surface area of the porous polyacrylonitrile fiber is 110m 2 / g. The SEM figure of gained porous polyacrylonitrile fiber surface is as follows figure 2 As shown, the SEM image of the obtained porous polyacrylonitrile fiber section is as follows image 3 As can be s...

Embodiment 2

[0039] (1) Dissolve acrylonitrile-itaconic acid binary copolymer in dimethyl sulfoxide to obtain a mixed solution with a mass fraction of 20%, and add polyvinylpyrrolidone to make a spinning solution; wherein, polyvinylpyrrolidone The dosage is 20% of the mass of acrylonitrile-itaconic acid binary copolymer;

[0040] (2) Extrude the spinning solution at 60°C, enter into water with a temperature of 60°C and solidify for 300 seconds to make fibers;

[0041] (3) The fibers obtained in step (2) were vacuum-dried at 60°C for 180 minutes to obtain porous polyacrylonitrile fibers.

[0042] The nitrogen adsorption-desorption curve of gained porous polyacrylonitrile fiber is as follows Figure 4 As shown, the specific surface area of the porous polyacrylonitrile fiber is 96m 2 / g.

Embodiment 3

[0044] (1) Dissolve acrylonitrile-itaconic acid binary copolymer in dimethyl sulfoxide to obtain a mixed solution with a mass fraction of 20%, and add polyvinylpyrrolidone to make a spinning solution; wherein, polyvinylpyrrolidone The dosage is 20% of the mass of acrylonitrile-itaconic acid binary copolymer;

[0045] (2) Extruding the spinning solution at 60°C, entering into an aqueous dimethyl sulfoxide solution with a temperature of 60°C and a mass fraction of 10 wt%, and coagulating for 300 seconds to form fibers;

[0046] (3) The fibers obtained in step (2) were vacuum-dried at 60°C for 180 minutes to obtain porous polyacrylonitrile fibers.

[0047] The nitrogen adsorption-desorption curve of gained porous polyacrylonitrile fiber is as follows Figure 5 As shown, the specific surface area of the porous polyacrylonitrile fiber is 95m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com