Method for preparing antibacterial surface on medical material surface

An antibacterial agent and surface modification technology, which is applied in the field of preparation of antibacterial surfaces, can solve problems such as performance mutual interference, anti-adhesion ability and bactericidal ability affecting surface antibacterial ability, and instability of polypeptide antibacterial agents, so as to reduce adverse effects and achieve excellent results. Long-term antibacterial performance, avoiding the effect of mutual interference of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

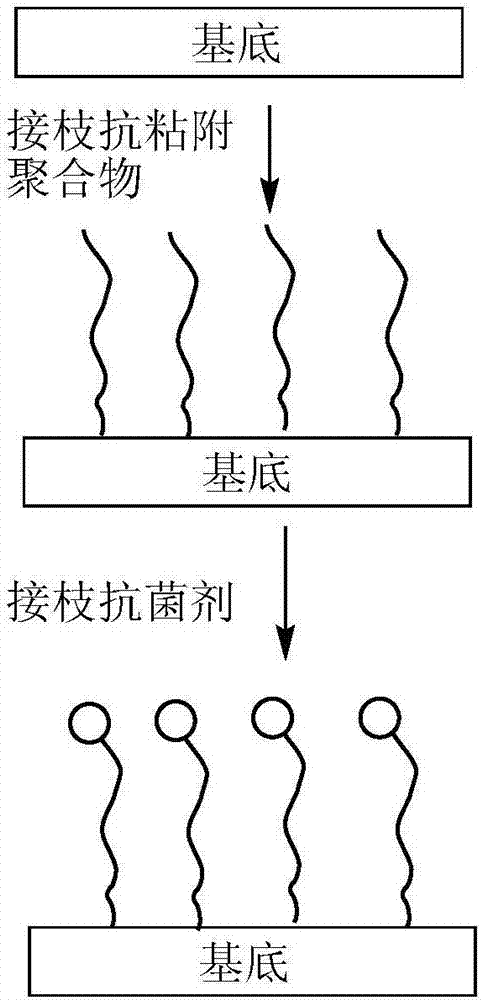

[0051] Such as figure 1 As shown, the method for preparing an antibacterial surface on the silicon wafer surface of the present embodiment may further comprise the steps:

[0052] (1) Perform oxygen plasma pretreatment on the surface of the silicon substrate, the working parameters are power 100W, pressure 20Pa, gas flow rate 300ml / min, temperature 30°C, time 5min; the pretreated silicon substrate is immersed in 3-aminopropyltri In the ethanol solution of ethoxysilane, aminosilane is chemically grafted on the surface of the silicon substrate, the reaction temperature is 30°C, and the time is 5h; wherein, the volume concentration of 3-aminopropyltriethoxysilane is 2%.

[0053] (2) Immerse the silicon substrate grafted with aminosilane on the surface in the dichloromethane solution of the acyl compound, and react with the acyl compound at a temperature of 20°C for 3 hours to prepare a silicon substrate with an atom transfer radical polymerization initiator modified surface Surf...

Embodiment 2

[0067] The method for preparing an antibacterial surface on the medical titanium surface of the present embodiment comprises the following steps:

[0068] (1) Perform oxygen plasma pretreatment on the surface of medical titanium, the working parameters are power 50W, pressure 30Pa, gas flow rate 30ml / min, temperature 30°C, time 3min; immerse the pretreated medical titanium surface in 3-aminopropyl In the ethanol solution of triethoxysilane, the reaction conditions for grafting aminosilane on the surface of medical titanium are as follows: 3-aminopropyltriethoxysilane volume concentration is 8%, temperature is 25°C, and time is 1h.

[0069] (2) Immerse the medical titanium on the surface of the grafted aminosilane in the dichloromethane solution of the acyl compound, and react with the acyl compound to obtain the silicon substrate surface of the initiator modified surface of the atom transfer radical polymerization; the reaction conditions are: The volume concentration of 2-bro...

Embodiment 3

[0074] The method for preparing an antibacterial surface on the medical titanium surface of the present embodiment comprises the following steps:

[0075] (1) Perform oxygen plasma pretreatment on the surface of medical titanium, the working parameters are power 400W, pressure 60Pa, gas flow rate 250ml / min, temperature 30°C, time 10min; immerse the pretreated medical titanium surface in 3-aminopropyl In the ethanol solution of triethoxysilane, aminosilane is grafted on the surface of medical titanium, the reaction conditions are: the volume concentration of 3-aminopropyltriethoxysilane is 8%, the temperature is 25°C, and the time is 0.5h.

[0076] (2) Immerse the medical titanium grafted with aminosilane on the surface in the solution of the acyl compound, and react with the acyl compound to prepare the surface of the silicon substrate modified by the atom transfer radical polymerization initiator; the reaction conditions are: 2-bromoisobutyl The volume concentration of acid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com