A kind of dairy cow breeding wastewater treatment process

A technology for aquaculture wastewater and a treatment process, which is applied in the field of dairy cattle breeding wastewater treatment technology, can solve the problems of high technical and economic difficulties in the discharge of ammonia nitrogen up to the standard, no enhanced denitrification function, poor wastewater treatment effect, etc., and achieves improved reaction efficiency, The effect of shortening the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

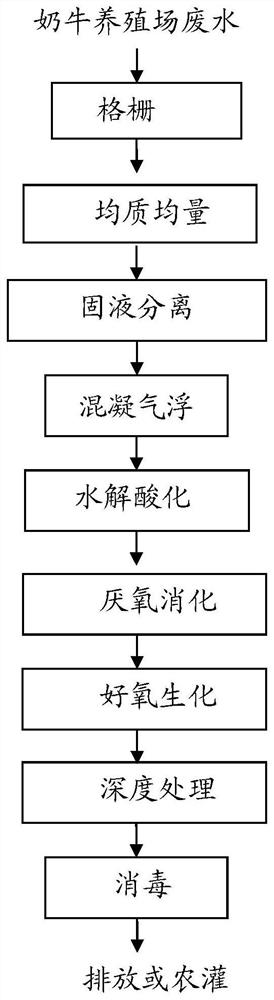

[0041] A dairy farming wastewater treatment process, comprising the following steps:

[0042] Step 1, pretreatment of dairy farming wastewater

[0043] Step 1.1, passing through the grille: Collect the cow urine, floor washing water, milking equipment cleaning water and farm domestic sewage produced in the dairy farm, and then pass through the rotary rake-toothed mechanical grille with a grid spacing of 40mm to remove Coarse solid debris in the waste water is discharged from the grid;

[0044] Step 1.2, homogenization and equalization: the water from the grille enters the storage and adjustment tank, and the pool water is stirred by the stirring device installed in the storage and adjustment tank to make the water quality uniform and obtain high-concentration raw water;

[0045]Step 1.3, solid-liquid separation: the high-concentration raw water is transported to the solid-liquid separator through a lifting pump, and filtered through a high-density screen with a size of 80 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com