Modified rosin resin, preparation method and printing ink using modified rosin resin

A technology for modifying rosin and resin, which is applied in the field of rosin modification, which can solve the problems of UV-curable inks such as the lack of ecological sustainability, and achieve the effects of shortened reaction time, low energy consumption, and good miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The embodiment of the present invention provides a kind of preparation method of modified rosin resin, comprises the following steps:

[0057] (1) In a 500mL three-necked flask with mechanical stirring and dropping funnel, add 60.5g (0.2mol) rosin and 34.00g (0.1mol) epoxy resin DER331, pass nitrogen to remove oxygen, heat up to 115°C, and react The product was melted, and then 0.76 g of triphenylphosphine was added, and stirred and reacted at 115° C. for 1.5 hours to obtain rosin-epoxy intermediate 1;

[0058] (2) Add 14.70 g (0.15 mol) of maleic anhydride to the rosin-epoxy intermediate 1 and react at 115°C for 2 hours to obtain the modified rosin resin 1.

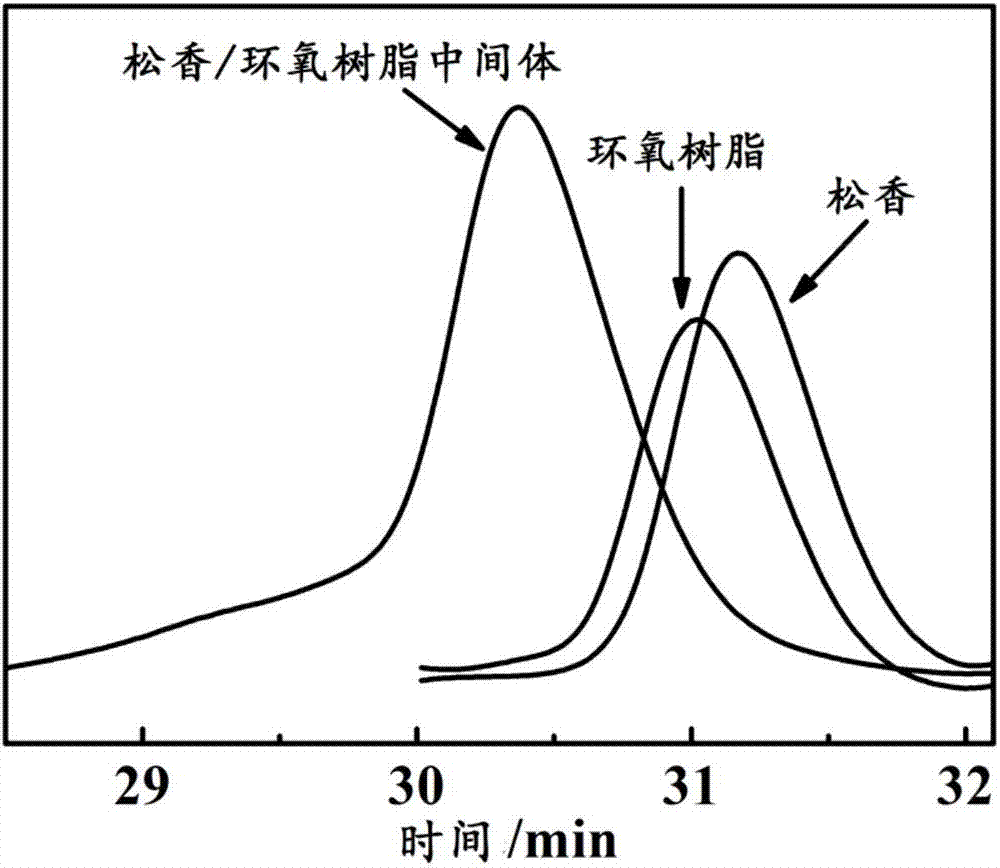

[0059] The GPC figure of the prepared rosin-epoxy intermediate one is shown in figure 1 ,Such as figure 1 As shown, the GPC curve of rosin-epoxy intermediate 1 moves to the high molecular weight part, and the peaks of raw material rosin and epoxy resin DER331 almost disappear, indicating that rosin and epoxy res...

Embodiment 2

[0066] The embodiment of the present invention provides a kind of preparation method of modified rosin resin, comprises the following steps:

[0067] (1) In a 500mL three-necked flask with mechanical stirring and dropping funnel, add 60.5g (0.2mol) rosin and 34.00g (0.1mol) epoxy resin DER331, pass nitrogen to remove oxygen, heat up to 115°C, and react The product was melted, and then 0.76 g of triphenylphosphine was added, and stirred and reacted at 115° C. for 2 hours to obtain rosin-epoxy intermediate 2;

[0068] (2) Add 9.8 g (0.1 mol) of maleic anhydride to the rosin-epoxy intermediate 2 and react at 115°C for 2 hours to obtain the modified rosin resin 2.

[0069] The number-average molecular weight of the prepared modified rosin resin II measured by GPC was 1110, and the weight-average molecular weight was 1620.

Embodiment 3

[0071] The embodiment of the present invention provides a kind of preparation method of modified rosin resin, comprises the following steps:

[0072] (1) In a 500mL three-necked flask with mechanical stirring and dropping funnel, add 60.5g (0.2mol) rosin and 34.00g (0.1mol) epoxy resin DER331, pass nitrogen to remove oxygen, heat up to 115°C, and react The product was melted, and then 0.76 g of triphenylphosphine was added, and stirred and reacted at 115° C. for 1.5 hours to obtain rosin-epoxy intermediate 3;

[0073] (2) Add 19.6 g (0.2 mol) of maleic anhydride to the rosin-epoxy intermediate 3 and react at 115°C for 2 hours to obtain the modified rosin resin 3.

[0074] The number-average molecular weight of the prepared modified rosin resin 3 measured by GPC was 1350, and the weight-average molecular weight was 1920.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com