Production method of 3,3-biethylene sulfate

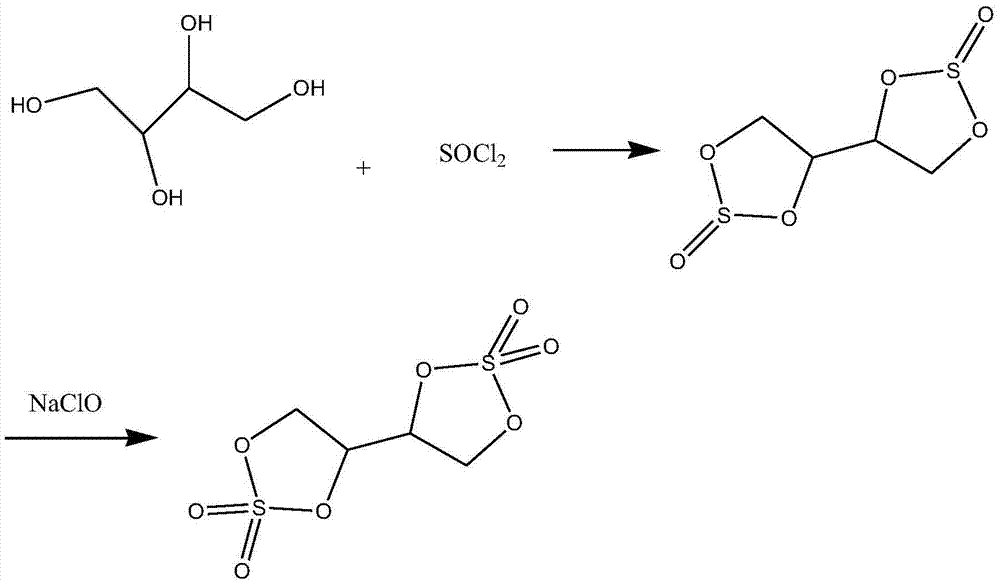

A technology of vinyl disulfate and vinyl disulfite, which is applied in the field of production of 3,3-vinyl disulfite, can solve the problems of affecting battery performance, affecting the reaction process, troublesome solvent handling, etc. Achieve the effects of preventing capacity reduction, avoiding hydrolysis, and improving purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

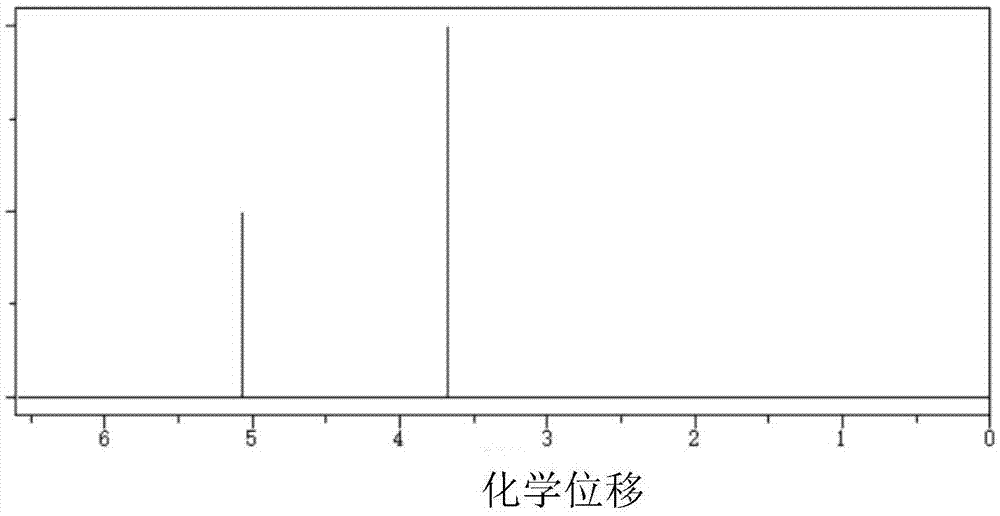

Examples

Embodiment 1

[0036] Step 1, using thionyl chloride and erythritol as reaction raw materials for addition reaction to obtain the intermediate 3,3-diethylene disulfite; adding thionyl chloride to the first reaction kettle and lowering the temperature To -15°C, add erythritol dropwise, fully react at -15°C to obtain the first reaction liquid, then carry out vacuum distillation on the first reaction liquid, and distill out the intermediate 3,3-bidia Vinyl sulfate is refluxed into the second reaction kettle by condensation and reflux; the molar ratio of thionyl chloride and erythritol is 3:1; the erythritol is added dropwise to the first reaction kettle by dropping at a constant speed , took 1 hour; the reaction time was 1 hour, the time to continue the reaction after adding erythritol dropwise; mechanical stirring was carried out in the first reaction kettle, so that thionyl chloride and erythritol fully contacted and reacted .

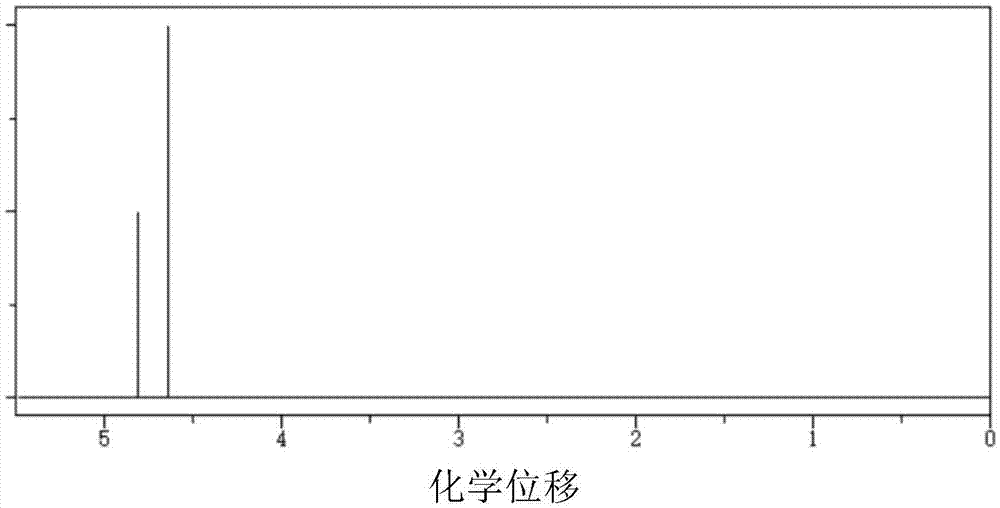

[0037] Step 2, intermediate oxidation reaction to obtain 3,3-di...

Embodiment 2

[0041] Step 1, using thionyl chloride and erythritol as reaction raw materials for addition reaction to obtain the intermediate 3,3-diethylene disulfite; adding thionyl chloride to the first reaction kettle and lowering the temperature To -10°C, add erythritol dropwise, and react fully at -10°C to obtain the first reaction solution, and then carry out vacuum distillation on the first reaction solution to distill out the intermediate 3,3-bidia Vinyl sulfate is refluxed into the second reaction kettle through condensation and reflux; the molar ratio of thionyl chloride and erythritol is 2:1; the erythritol is added dropwise to the first reaction kettle by dropping at a constant speed , during 2 hours; the reaction time was 3 hours, and the reaction time included the time of dripping erythritol, and the time to continue the reaction after dripping erythritol; ultrasonic dispersion was carried out in the first reactor, so that Thionyl chloride and erythritol fully contact and reac...

Embodiment 3

[0046] Step 1, using thionyl chloride and erythritol as reaction raw materials for addition reaction to obtain the intermediate 3,3-diethylene disulfite; adding thionyl chloride to the first reaction kettle and lowering the temperature To -5°C, add erythritol dropwise, fully react at -5°C to obtain the first reaction liquid, then carry out vacuum distillation on the first reaction liquid, and distill out the intermediate 3,3-bidia Vinyl sulfate is refluxed into the second reaction kettle by condensation and reflux; the molar ratio of thionyl chloride and erythritol is 1:1; erythritol is added dropwise to the first reaction kettle by dropping at a constant speed , with a time of 1.5 hours; the reaction time was 3 hours, and the reaction time was the time for continuing the reaction after dripping erythritol; ultrasonic dispersion was carried out in the first reaction kettle, so that thionyl chloride and erythritol were fully Touch and react.

[0047] Step 2, intermediate oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com