Conductive air-ventilating and liquid-blocking film and preparation and application thereof

A technology of liquid-resistant and conductive materials, applied in electrical components, circuits, fuel cells, etc., can solve problems such as restricting applications, unfavorable uniform distribution of PTFE and carbon powder, affecting membrane mechanics, electrical conductivity, and air permeability and liquid resistance. content, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]A conductive air-permeable liquid-resistance film, the composition of which comprises: PTFE with a mass fraction of 60% and acetylene black with a mass fraction of 40%.

[0035] Weigh 12g of acetylene black powder into a 2L three-neck glass flask, then add the PTFE solution diluted 100 times by mass, and add an equal volume of deionized water at the same time, maintain the system temperature at 80°C, mechanically stir and disperse for 2 hours, and keep stirring The speed is not lower than 800rpm. After the stirring and mixing are completed, the water is removed by centrifugation, and then the obtained solid dough is further dried in an air oven until the water content is not more than 1%. Grind the dried solid into a fine powder, add equal mass of ethanol and knead for 60 times, then place it on the roller machine, set the distance between the rollers to 3mm, maintain the temperature of the roller film at 25°C, and roll it 10 times into a blank; turn down the roller spa...

Embodiment 2

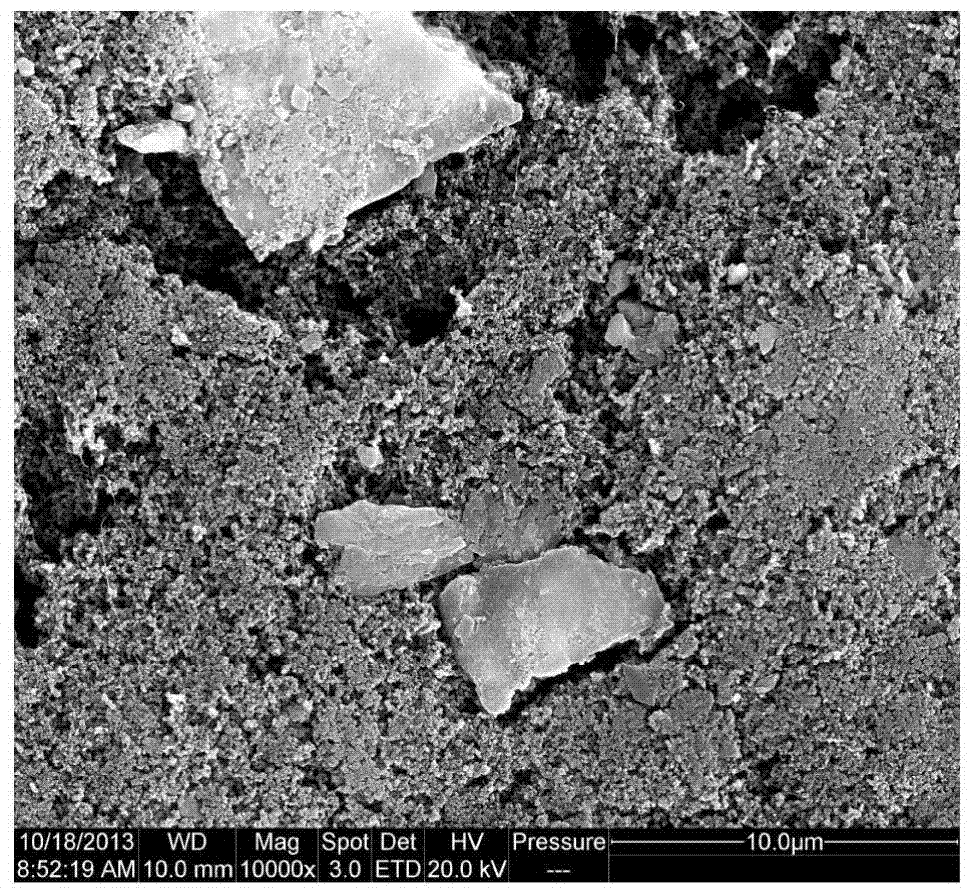

[0040] The difference between this embodiment and Embodiment 1 is that the composition of the conductive air-permeable liquid-resistant film of this embodiment includes: PTFE with a mass fraction of 33% and acetylene black with a mass fraction of 67%. Figure 5 It is the SEM image of the film after heat treatment.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is that the composition of the conductive air-permeable liquid-resistant film of this embodiment includes: PTFE with a mass fraction of 15% and acetylene black with a mass fraction of 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com