Preparation method of alogliptin benzoate tablet high in bioavailability

A technology of alogliptin tablets and benzoic acid, which is applied in the field of preparation of alogliptin benzoate tablets, can solve the problems of affecting human absorption, slow disintegration, and lowering the level of hemoglobin Alc, so as to speed up the disintegration speed and speed up Absorption, bioavailability enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

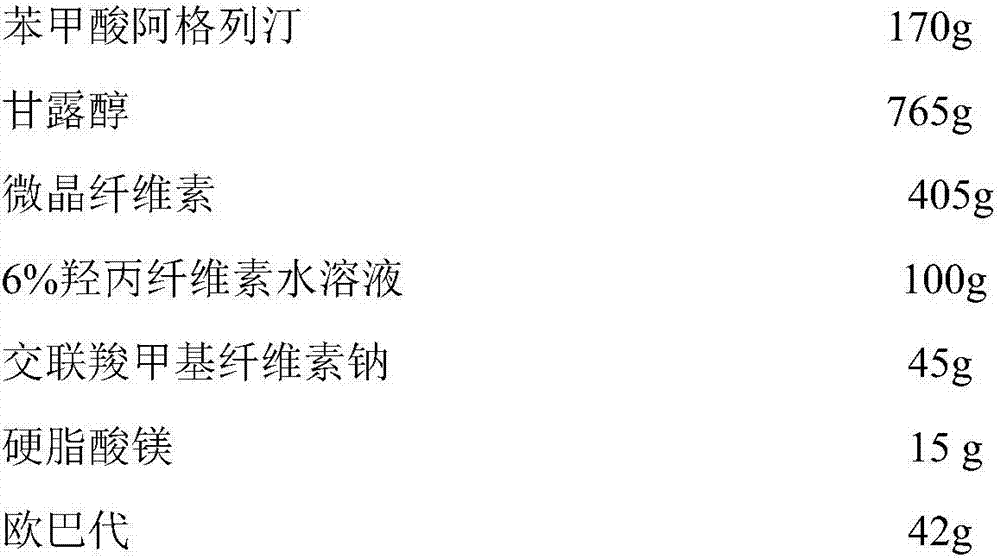

[0026] Alogliptin Benzoate Tablets (Specification: 12.5mg (calculated as alogliptin), 10,000 tablets in total)

[0027]

[0028] Preparation method:

[0029] (1) Weigh the raw material of alogliptin benzoate through micronization and pass through a 120 mesh sieve, mannitol, microcrystalline cellulose, hypromellose, cross-linked carmellose sodium pass through a 80 mesh sieve, stearin Magnesium acid is passed through a 40-mesh sieve for subsequent use.

[0030] (2) Take alogliptin benzoate, mannitol, microcrystalline cellulose, and croscarmellose sodium in the prescribed amount by weighing and mix them evenly, then add the adhesive soft material in the prescribed amount, and pass through a 20-mesh sieve. grain. The prepared wet granules are air-dried at 50-60°C.

[0031] (3) The dry granules are passed through an 18-mesh sieve for granulation, and the prescription amount of magnesium stearate is added and mixed evenly to obtain mixed granules.

[0032] (4) Determining the...

Embodiment 2

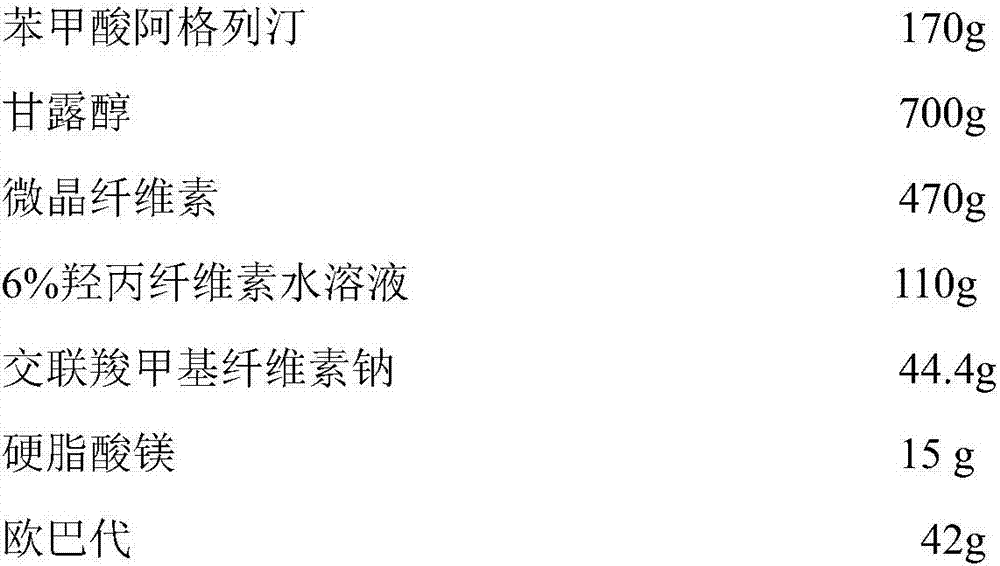

[0035] Alogliptin Benzoate Tablets (Specification: 12.5mg (calculated as alogliptin), 10,000 tablets in total)

[0036]

[0037] The preparation method is the same as in Example 1, and 10,000 alogliptin benzoate tablets can be obtained.

Embodiment 3

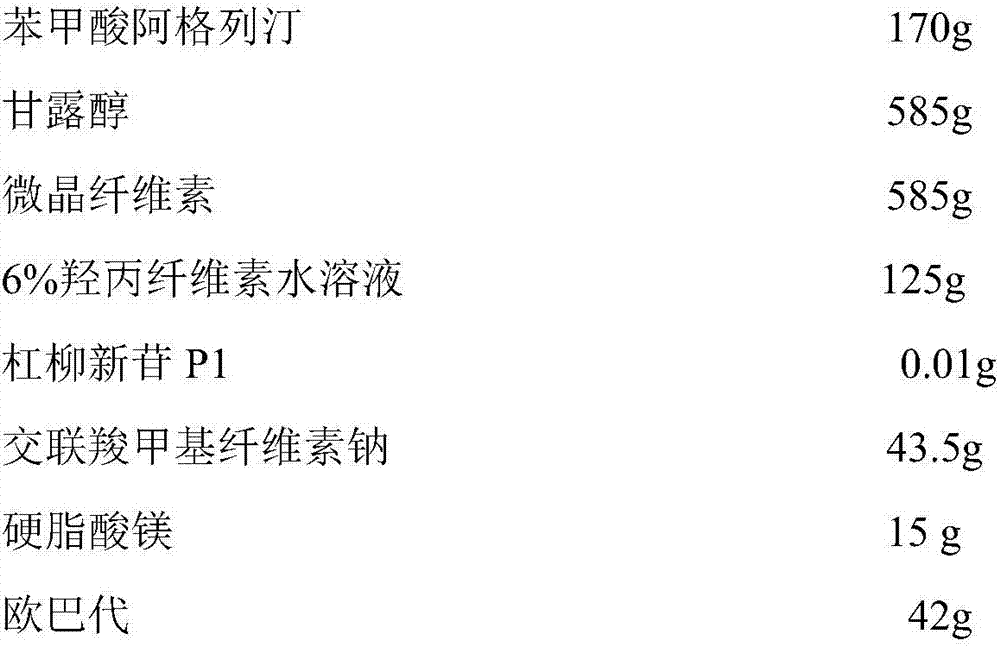

[0039] Alogliptin Benzoate Tablets (Specification: 12.5mg (calculated as alogliptin), 10,000 tablets in total)

[0040]

[0041] The croscarmellose sodium was premixed with the new glucoside P1, and the other preparation methods were the same as in Example 1, and 10,000 alogliptin benzoate tablets could be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com