Supported noble metal nanoparticle composite material and preparation method thereof

A nanoparticle and composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor uniformity of metal nanoparticles, wide particle size distribution range, harsh reaction conditions, etc. Achieve the effects of stable combination, narrow distribution range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

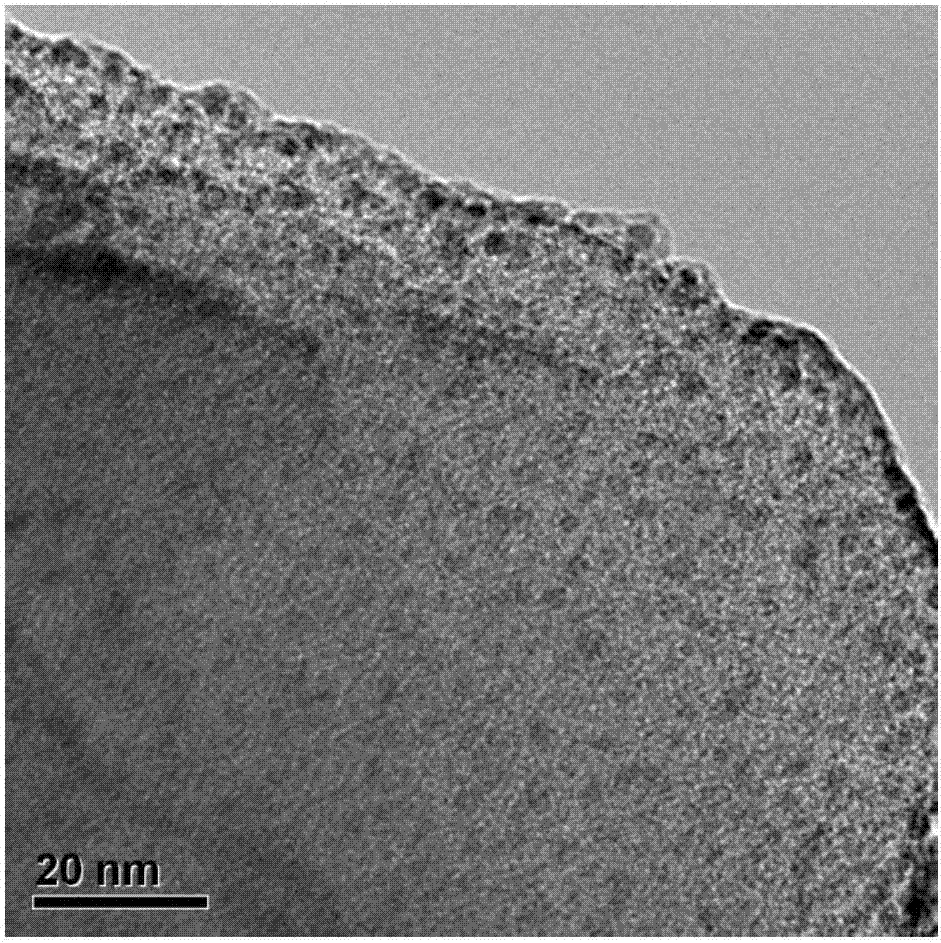

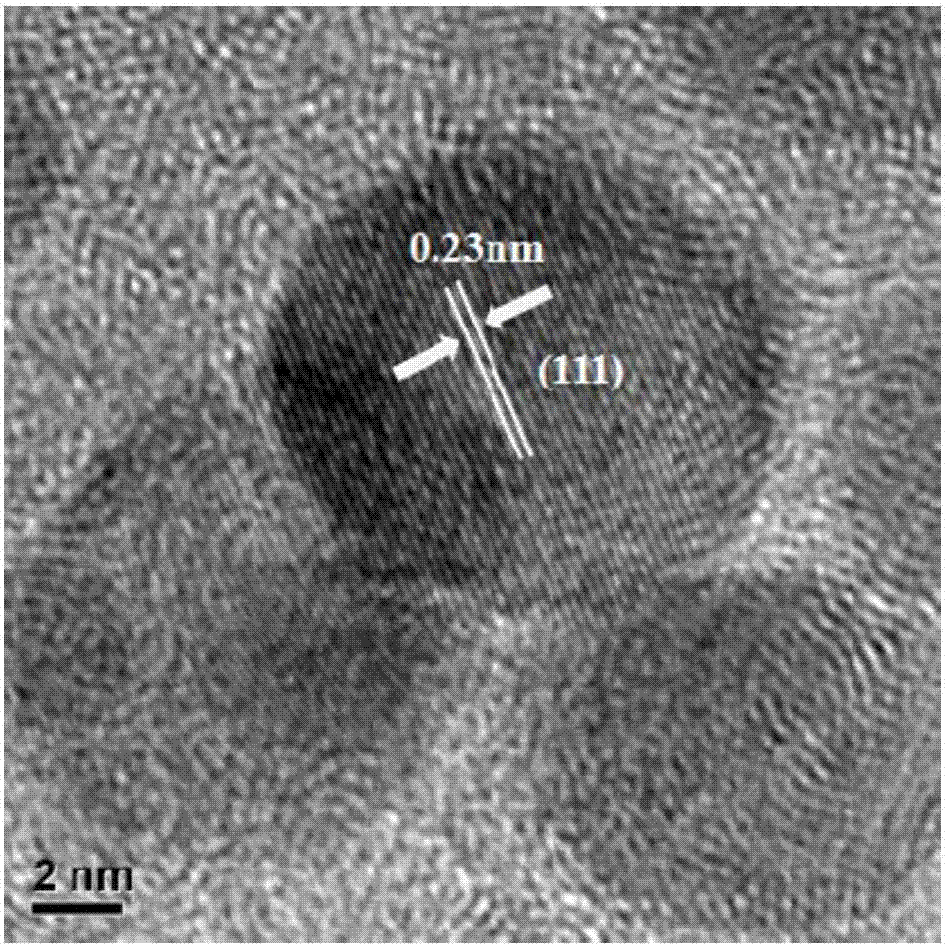

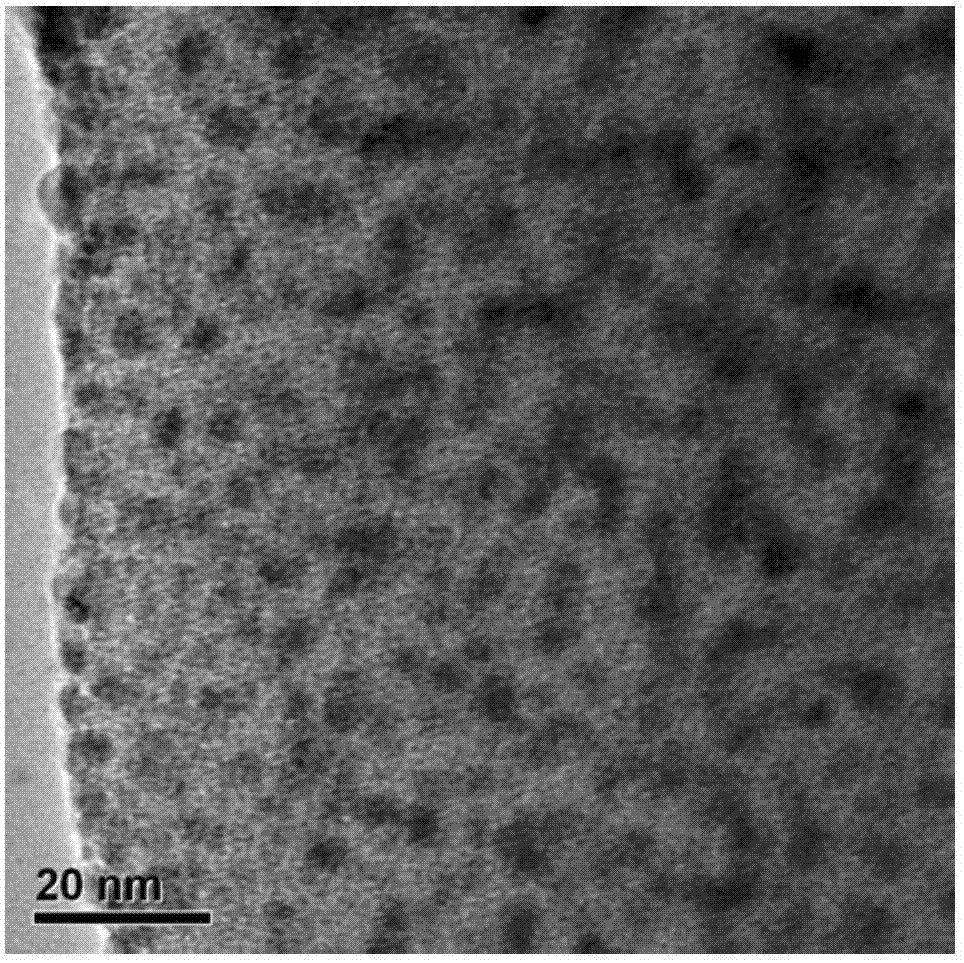

Embodiment 1

[0060] First, according to the literature (Li, H.; Ma, H.; Wang, X.; Gao, J.; Chen, C.; Shi, S.; Qu, M.; Feng, N.; Xu, J. Journal of Energy Chemistry 2014,23,742) ZIF-67 was prepared. Weigh 20 mg of ZIF-67 powder, dissolve it in 10 ml of methanol, and dissolve it ultrasonically for 10 minutes to obtain a purple suspension system. Prepare 50mM chloropalladium acid aqueous solution. Use a pipette to transfer 300 μL of the chloropalladium acid aqueous solution, slowly drop it into the ZIF-67 methanol solution system (that is, the purple suspension system described above), and stir for 6 hours to complete the immersion process. Weigh 7.2 mg of sodium borohydride, dissolve it in 1 ml of cooled methanol, dissolve it ultrasonically for 10 seconds, and add the obtained dispersion to the impregnation system after the impregnation, and the system changes from purple to black. Continue stirring for 1 h, then centrifuge at 8000 rpm for 10 min, separate the clear liquid, and wash it repea...

Embodiment 2

[0064] ZIF-67 was prepared by the same method as in Example 1. Weigh 20 mg of ZIF-67 powder, dissolve it in 10 ml of methanol, and dissolve it ultrasonically for 10 minutes to obtain a purple suspension system. Prepare 50mM chloroplatinic acid aqueous solution. Use a pipette to transfer 300 μL of the chloroplatinic acid aqueous solution, slowly drop it into the ZIF-67 methanol solution system (that is, the purple suspension system described above), and stir for 6 hours to complete the immersion process. Weigh 7.2 mg of sodium borohydride, dissolve it in 1 ml of cooled methanol, dissolve it ultrasonically for 10 seconds, and add the obtained dispersion to the impregnation system after the impregnation, and the system changes from purple to black. Continue stirring for 1 h, then centrifuge at 8000 rpm for 10 min, separate the clear liquid, and wash it repeatedly with methanol 3 times. The samples were dried at room temperature and protected from light for 12 hours to obtain a Z...

Embodiment 3

[0068] First, ZIF-67 was prepared by the same method as in Example 1. Weigh 20 mg of ZIF-67 powder, dissolve it in 10 ml of methanol, and dissolve it ultrasonically for 10 minutes to obtain a purple suspension system. Prepare 50mM chloroauric acid aqueous solution. Use a pipette to transfer 300 μL of the chloroauric acid aqueous solution, slowly drop it into the ZIF-67 methanol solution system (that is, the purple suspension system described above), and stir for 6 hours to complete the immersion process. Weigh 7.2 mg of sodium borohydride, dissolve it in 1 ml of cooled methanol, dissolve it ultrasonically for 10 seconds, and add the obtained dispersion to the impregnation system after the impregnation, and the system changes from purple to black. Continue stirring for 1 h, then centrifuge at 8000 rpm for 10 min, separate the clear liquid, and wash it repeatedly with methanol 3 times. The samples were dried at room temperature and protected from light for 12 hours to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com