Durable polysilsesquioxane nano hybrid super-hydrophobic leather coating layer and preparation method thereof

A polysilsesquioxane and durability technology, which is applied in the field of preparation of durable polysilsesquioxane nano-hybrid superhydrophobic leather coatings, can solve problems such as lack of application methods, achieve improved friction resistance, The effect of easy availability of raw materials and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

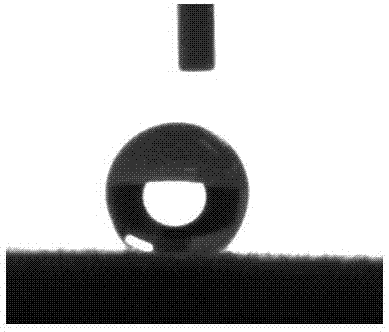

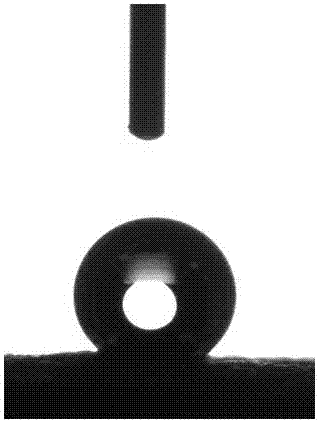

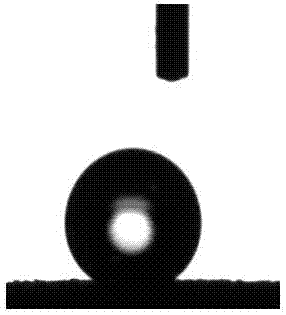

Image

Examples

preparation example Construction

[0033] A preparation method of durable polysilsesquioxane nano-hybrid superhydrophobic leather coating, comprising the following steps:

[0034] Step 1: Add aminosilane and isopropanol with a mass ratio of 5:1 into the reaction kettle, heat to 65°C, and stir for half an hour; add maleic anhydride in 5 batches, and the molar ratio of maleic anhydride to aminosilane is 1.1: 1. After the dropwise addition, keep the temperature for 3 hours, and the reaction is completed, and the carboxylated silane monomer (CTES) is obtained;

[0035] Step 2: Add sodium lauryl sulfate, AEO-3, NaOH catalyst and distilled water into the reaction kettle, stir at 15-25°C for 60 minutes; then slowly add methylsilane monomer dropwise at a rate of 20 drops / min, Continue to stir for 1.5-2.5 hours after dropping, then add carboxylated silane monomer (CTES) dropwise at the same dropping speed, and keep warm for 12 hours after dropping to prepare anionic narrowly dispersed polycarboxy / methylsilsesquioxane (...

Embodiment 1

[0050] (1) Add 20g of KH550 and 4g of isopropanol into the reaction kettle in sequence, heat to 65°C, and stir for 30 minutes. Then, start to add 9.8g maleic anhydride in 5 batches, after the dropwise addition is completed, keep the temperature for 3 hours, and the reaction is completed, and the carboxylated silane monomer (CTES) is obtained;

[0051] (2) Accurately weigh 3.8g sodium lauryl sulfate, 3.8g AEO-3, 4.5g NaOH and 1500g distilled water, add them into the reaction kettle, and stir at room temperature (25°C) for 60min. Then, start to slowly add 120g of methylsilane monomer (MTES) dropwise, control the drop rate (20 drops / min), continue to stir for 2.0h after the drop, and then start to drop the carboxyl group prepared in step (1) at the same drop rate Silane monomer (CTES), after dropping, keep warm for 12 hours to prepare anionic narrowly dispersed polycarboxy / methylsilsesquioxane (PCMSQ) nanosphere hybrid emulsion (average particle size is 106.9nm, PDI is 0.20);

...

Embodiment 2

[0057] (1) Add 20g of aminopropyltrimethoxysilane and 4g of isopropanol into the reaction kettle in sequence, heat to 65°C, and stir for 30min. Then, start to add 12.0 g of maleic anhydride in 5 batches, after the dropwise addition is completed, keep the temperature for 3 hours, and the reaction is completed, and the carboxylated silane monomer (CTES) is obtained;

[0058] (2) Accurately weigh 7.4g sodium lauryl sulfate, 7.4g AEO-3, 3.2g NaOH and 1920g distilled water, add them into the reaction kettle, and stir at room temperature (25°C) for 60min. Then, start to slowly add 128g of methylsilane monomer (MTMS) dropwise, control the drop rate (20 drops / min), continue to stir for 2.0h after the drop, and then start to drop the carboxyl group prepared in step (1) at the same drop rate Silane monomer (CTES), after dripping, keep warm for 12 hours to prepare anionic narrowly dispersed polycarboxy / methylsilsesquioxane (PCMSQ) nanosphere hybrid emulsion (average particle size is 66.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com