A kind of multi-layer laundry sheet and preparation method thereof

A laundry tablet and single-chip technology, applied in the field of daily chemical washing, can solve the problems of easy loss of function, difficulty in exerting effects, unstable antibacterial agent, etc., and achieve the effects of improving washing performance, saving costs, and protecting activity

- Summary

- Abstract

- Description

- Claims

- Application Information

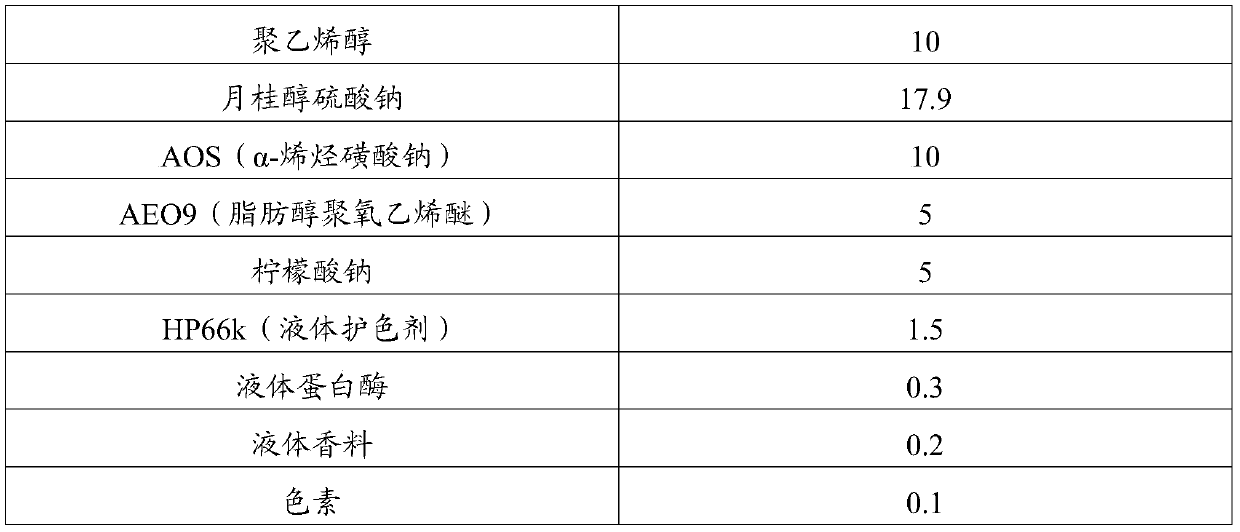

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

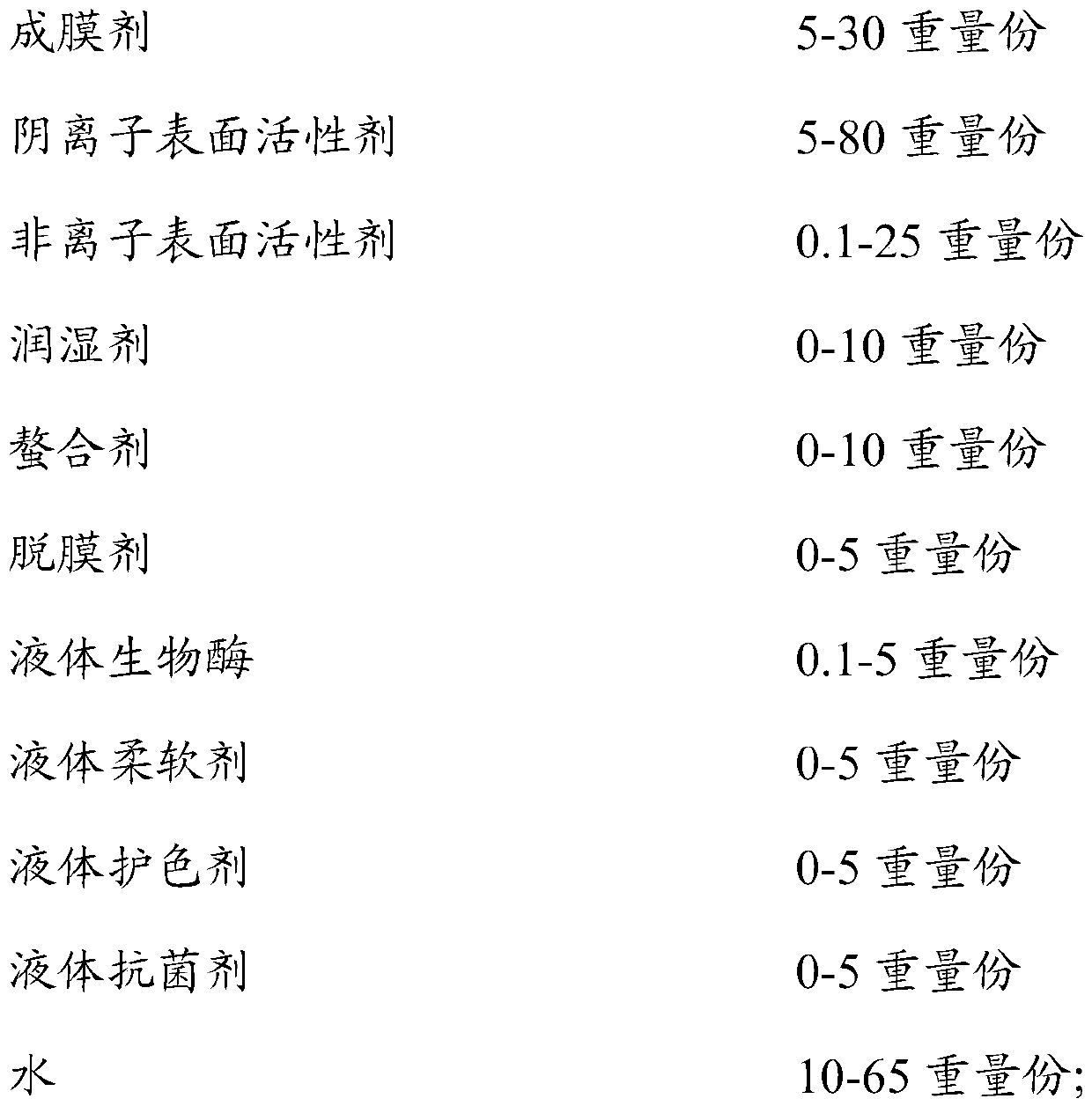

[0046]The formula of the multi-layer laundry sheet of the present embodiment is as shown in Table 1.

[0047] Table 1

[0048] components mass, g Deionized water 56 polyvinyl alcohol 9 Sodium dodecyl benzene sulfonate 12 AOS (Sodium Alpha Olefin Sulfonate) 9 AEO9 (fatty alcohol polyoxyethylene ether) 4 Sodium citrate 4 glycerin 3.3 white oil 2 liquid protease 0.2 liquid amylase 0.2 liquid spice 0.2 pigment 0.1

[0049] Add 9g of polyvinyl alcohol and 56g of deionized water into the batching pot, stir for 30 minutes to pre-dissolve, and control the temperature at 60°C until completely dissolved; add 12g of sodium dodecylbenzenesulfonate, 9g of AOS, 4g of AEO9, 3.3g of Glycerin, 4g sodium citrate, 2g white oil and 0.1g pigment, the temperature of the batching pot is controlled at 80°C, and stirred for 50 minutes to obtain a uniform slurry; transfer the slurry to a drying drum at 80°C, and dry ...

Embodiment 2

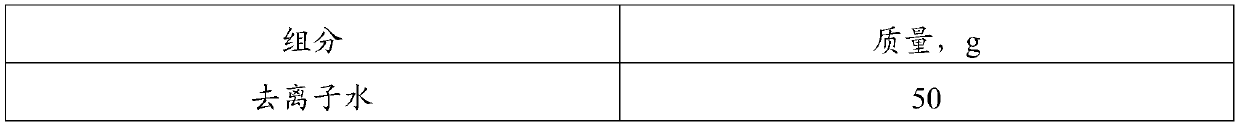

[0051] The formula of the multi-layer laundry sheet of the present embodiment is as shown in Table 2.

[0052] Table 2

[0053] components mass, g Deionized water 50 polyvinyl alcohol 10 Sodium dodecyl benzene sulfonate 8 sodium lauryl sulfate 15 AEO9 (fatty alcohol polyoxyethylene ether) 6 Disodium edetate 5 Propylene Glycol 2.3 white oil 3 liquid protease 0.2 liquid cellulase 0.2 liquid spice 0.2 pigment 0.1

[0054] Add 10g of polyvinyl alcohol and 50g of deionized water into the batching pot, stir for 40 minutes to pre-dissolve, and control the temperature at 65°C until completely dissolved; add 8g of sodium dodecylbenzenesulfonate, 15g of sodium lauryl sulfate, 6g AEO9, 2.3g propylene glycol, 5g disodium ethylenediamine tetraacetate, 3g white oil and 0.1g pigment, the temperature of the batching pot is controlled at 70°C, and stirred for 45min to obtain a uniform slurry; transfer the sl...

Embodiment 3

[0056] The formula of the multi-layer laundry sheet of the present embodiment is as shown in table 3.

[0057] table 3

[0058] components mass, g Deionized water 50 polyvinyl alcohol 8 Polyvinylpyrrolidone 3 sodium lauryl sulfate 15 AES (sodium fatty alcohol polyoxyethylene ether sulfate) 8 6501 (coconut oil fatty acid diethanolamide) 5 Sodium citrate 5 Isopropanol 2.3 white oil 3 liquid protease 0.3 liquid spice 0.3 pigment 0.1

[0059] Add 8g of polyvinyl alcohol, 3g of polyvinylpyrrolidone and 50g of deionized water into the batching pot, stir and pre-dissolve for 50 minutes, and control the temperature at 70°C until completely dissolved; add 15g of sodium lauryl sulfate, 8gAES, 5g6501, 2.3g of isopropanol, 5g of sodium citrate, 3g of white oil and 0.1g of pigment, the temperature of the batching pot is controlled at 70°C, and stirred for 40min to obtain a uniform slurry; the slurry is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com