Method for changing wettability of liquid drops on surface of high-temperature solid

A high-temperature solid, wettable technology, applied in ion implantation plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

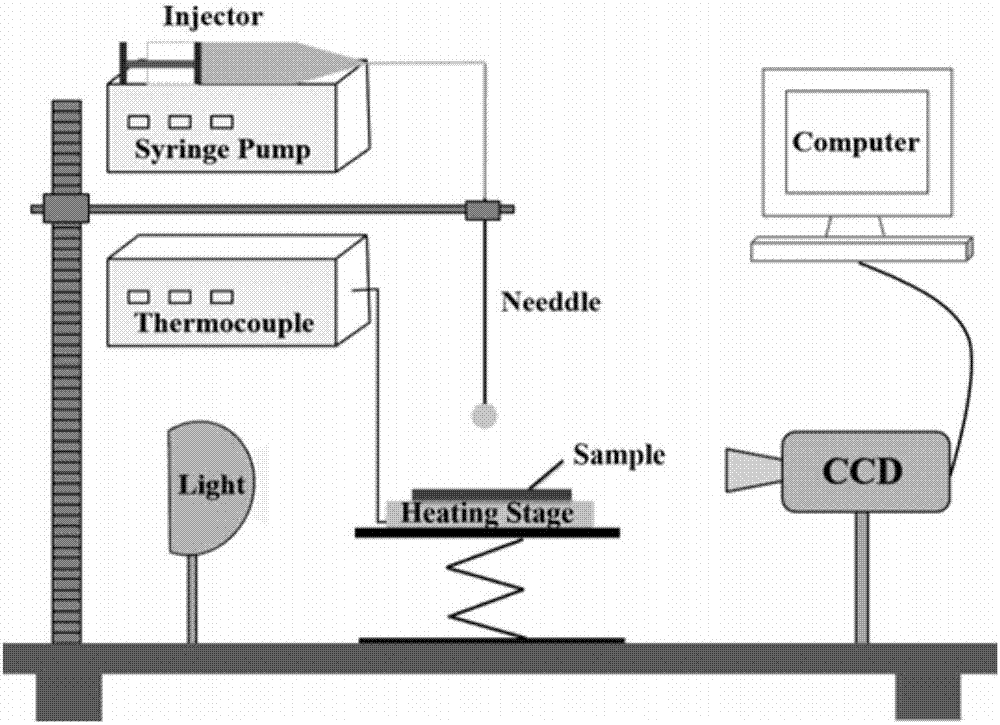

Method used

Image

Examples

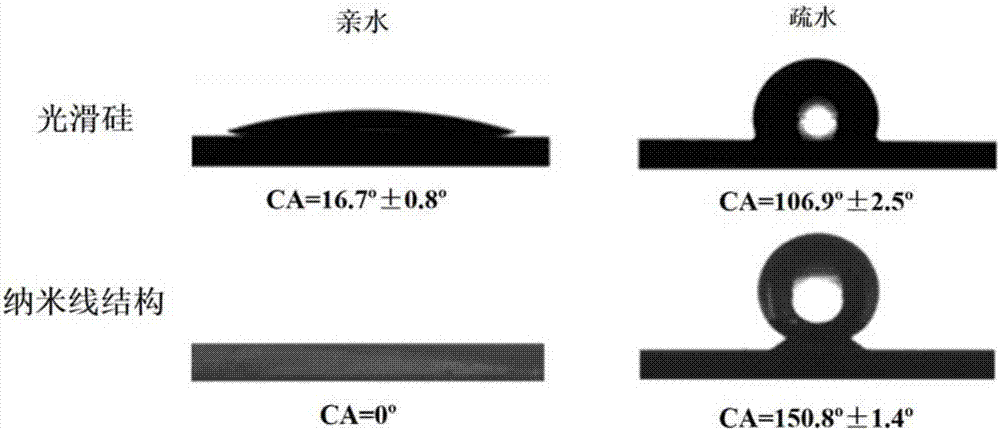

Embodiment 1

[0060] In this embodiment, the working liquid droplet uses a surfactant sodium dodecylsulfonate SDS solution, and the base material is a smooth silicon wafer.

[0061] The first step is the selection of working droplets;

[0062] In the first step, the surfactant sodium dodecylsulfonate SDS solution is selected as the working droplet, and the configuration is 0mol / L, 1.0×10 -3 mol / L, 4.0×10 -3 mol / L, 9.0×10 -3 mol / L, 1.0×10- 2 mol / L aqueous solution of sodium dodecylsulfonate.

[0063] The second step is the cleaning of the silicon wafer;

[0064] The second step is further specifically immersing the smooth silicon wafer (P-type, crystal orientation 100) in acetone and ethanol for 15 minutes, followed by rinsing with water, and then immersing in a solution with a volume ratio of 98% sulfuric acid and hydrogen peroxide at a volume ratio of 3:1. , heated at 80°C for 30 minutes, took it out and washed it with a large amount of water, at this time the silicon wafer is hydroph...

Embodiment 2

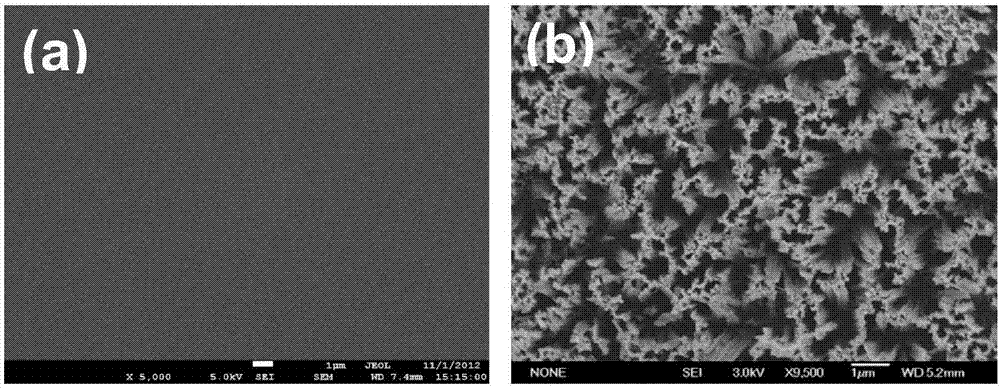

[0071] In this embodiment, the working droplets use SiO 2 Nanofluid, the base material is silicon nanowire structure.

[0072] The first step is the selection of working droplets;

[0073] The first step selects SiO 2 Nanofluids as working droplets. Prepare nanofluids of 0g / L, 0.05g / L, 0.1g / L, 0.2g / L, and 0.3g / L, but place them in 100mL volumetric flasks for future use. Due to the small size effect of nanoparticles, agglomeration is easy to occur, so ultrasonic dispersion should be carried out in an ultrasonic machine during the preparation process, and the ultrasonic time is 10h. Ultrasonic dispersion should be carried out in the ultrasonic machine before the next use to avoid the agglomeration of nanoparticles and affect the experimental results

[0074] The second step is the cleaning of the silicon wafer;

[0075] Soak a smooth silicon wafer (type P, crystal orientation 100) in acetone and ethanol for 15 minutes, rinse with water, then immerse in a solution of 98% sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com