Electrically active ta-ha composite nerve guide and preparation method thereof

A TA-HA, nerve catheter technology, applied in prosthesis, tissue regeneration, medical science and other directions, can solve the problems of sacrificing secondary nerve function, clinical application limitations, limited nerve sources, etc., to achieve good biocompatibility, reduce Toxic and side effects, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

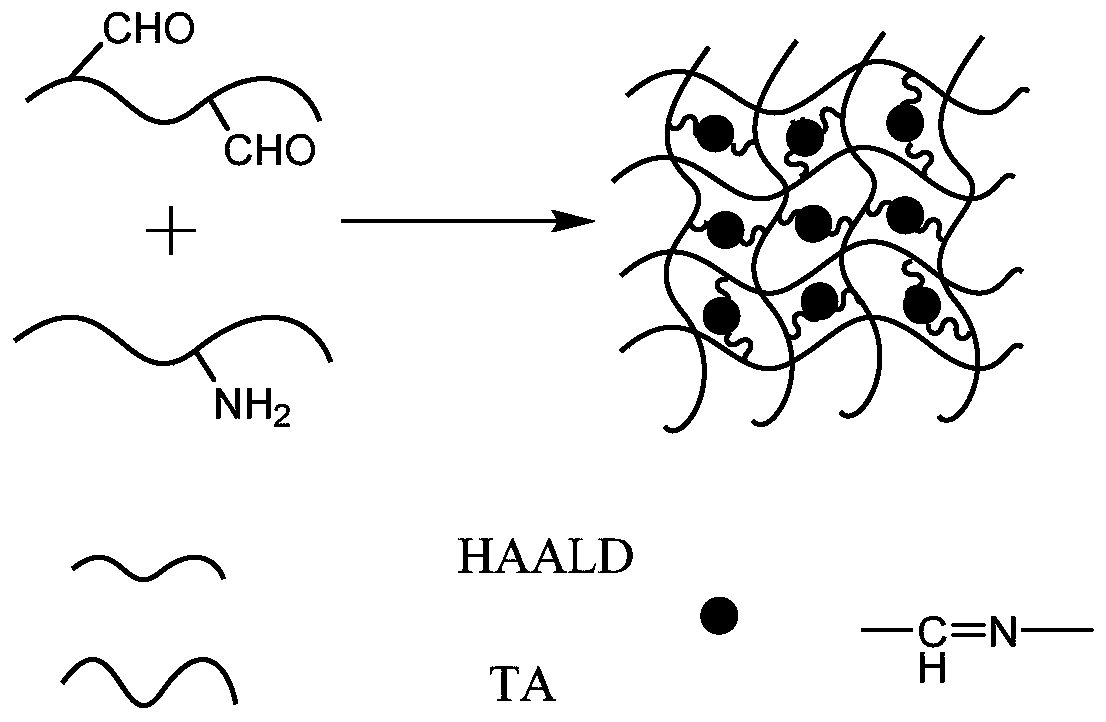

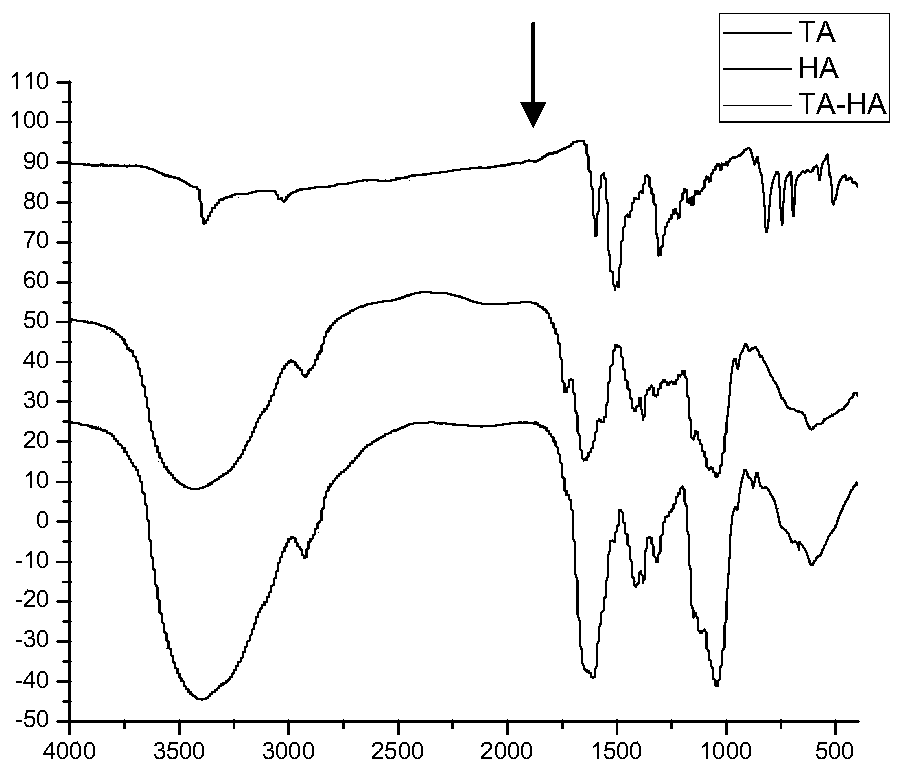

Method used

Image

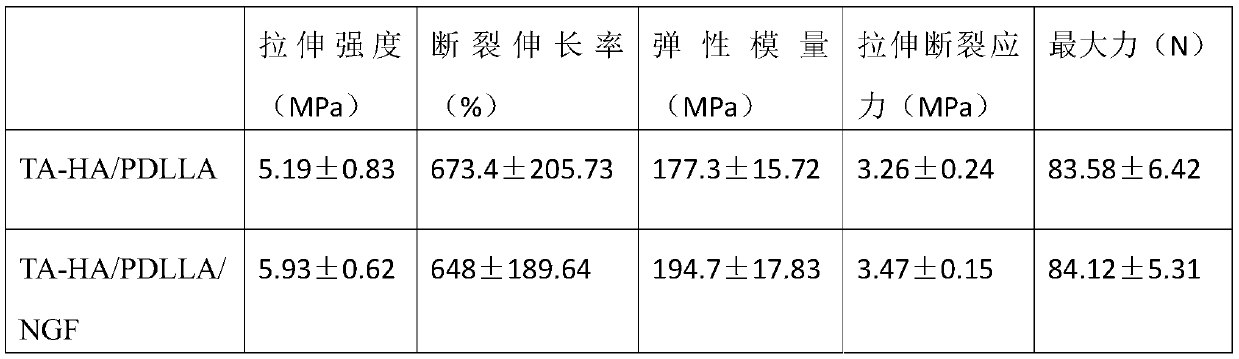

Examples

Embodiment 1

[0025] 1) Formylated HAALD of hyaluronic acid:

[0026] Dissolve 0.1g of hyaluronic acid in 50mL of deionized water, adjust the pH between 5-6, dissolve under magnetic stirring, add 10ml of 0.25mol / L sodium periodate, react at room temperature for 4-5h, add 10ml of ethylene glycol Alcohol terminated the reaction, dialyzed for three days, changed the water, removed unreacted substances, and obtained powdered formylated hyaluronic acid after freeze-drying.

[0027] 2) Preparation of TA:

[0028] Dissolve 0.5g of N-phenyl-p-phenylenediamine in a precooled mixed solvent of 1mol / L HCl and acetone, stir magnetically at 0°C, dissolve 0.5g of ammonium persulfate in a mixed solvent of acetone and water, and Ammonium sulfate was slowly added dropwise to the N-phenyl-p-phenylenediamine system, stirred magnetically for 3 h, washed and filtered, counter-doped with 0.1 mol / L ammonia water, then reduced with 5 ml of phenylhydrazine, filtered, and vacuum-dried to obtain TA powder.

[0029] ...

Embodiment 2

[0039] 1) Formylated HAALD of hyaluronic acid:

[0040] Dissolve 0.1g of hyaluronic acid in 50mL of deionized water, adjust the pH between 5-6, dissolve under magnetic stirring, add 15ml of 0.25mol / L sodium periodate, react at room temperature for 4-5h, add 20ml of ethylene glycol Alcohol terminated the reaction, dialyzed for three days, changed the water, removed unreacted substances, and obtained powdered formylated hyaluronic acid after freeze-drying.

[0041] 2) Preparation of TA:

[0042] Dissolve 0.5g of N-phenyl-p-phenylenediamine in a precooled mixed solvent of 1.5mol / L HCl and acetone, stir magnetically at 0°C, dissolve 0.8g of ammonium persulfate in a mixed solvent of acetone and water, and Ammonium sulfate was slowly added dropwise to the N-phenyl-p-phenylenediamine system, stirred magnetically for 3 hours, washed and filtered, counter-doped with 0.15mol / L ammonia water, then reduced with 5ml of phenylhydrazine, filtered, and vacuum-dried to obtain TA powder.

[0...

Embodiment 3

[0048] 1) Formylated HAALD of hyaluronic acid:

[0049] Dissolve 0.2g of hyaluronic acid in 50mL of deionized water, adjust the pH between 5-6, dissolve under magnetic stirring, add 10ml of 0.25mol / L sodium periodate, react at room temperature for 4-5h, add 10ml of ethylene glycol Alcohol terminated the reaction, dialyzed for three days, changed the water, removed unreacted substances, and obtained powdered formylated hyaluronic acid after freeze-drying.

[0050] 2) Preparation of TA:

[0051] Dissolve 0.5g of N-phenyl-p-phenylenediamine in a precooled mixed solvent of 1mol / L HCl and acetone, stir magnetically at 0°C, dissolve 0.5g of ammonium persulfate in a mixed solvent of acetone and water, and dissolve the persulfuric acid Ammonium was slowly added dropwise to the N-phenyl-p-phenylenediamine system, stirred magnetically for 5 hours, washed and filtered, counter-doped with 0.1mol / L ammonia water, then reduced with 10ml of phenylhydrazine, filtered, and vacuum-dried to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com