Metal atom-containing nano carbon material as well as preparation method and application thereof and hydrocarbon dehydrogenation reaction method

A nano-carbon material, metal atom technology, applied in nanotechnology, nanotechnology, hydrocarbons and other directions, can solve problems such as lack of consensus, achieve small structural impact, improve raw material conversion rate and product selectivity, and good catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

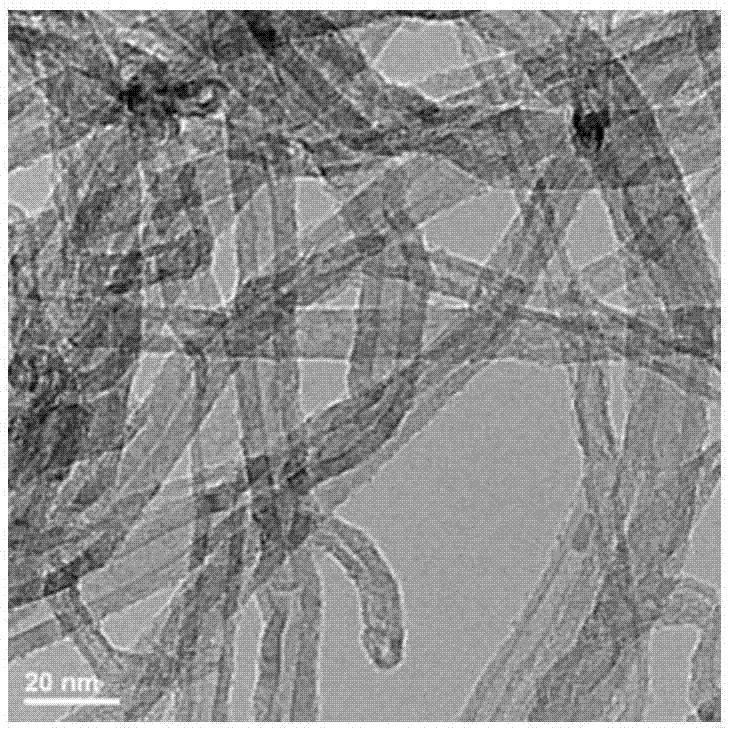

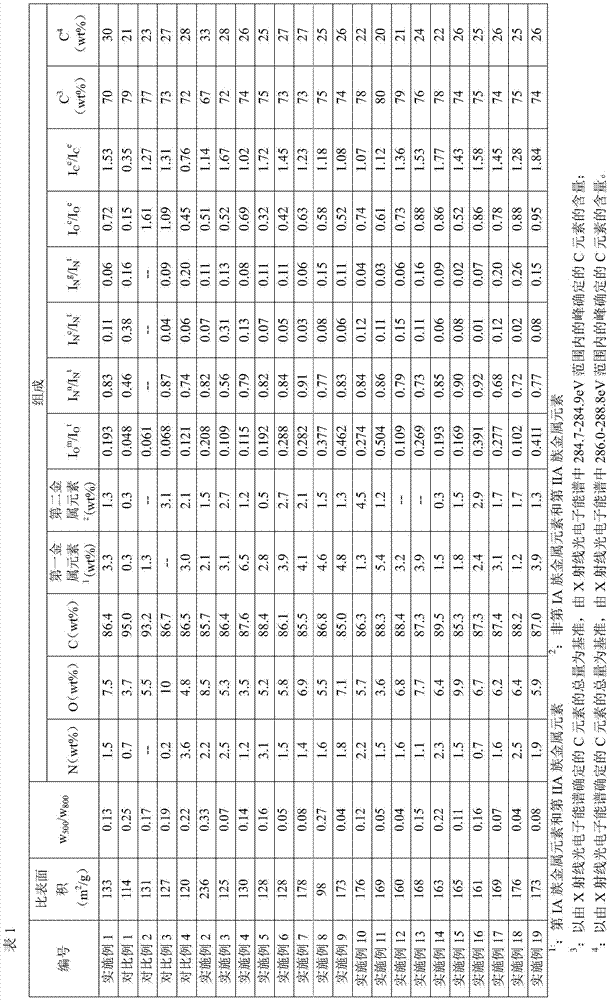

Embodiment 1

[0098] (1) 20g of multi-walled carbon nanotubes (specific surface area is 136m 2 / g, the content of oxygen atom is 0.3% by weight, the content of nitrogen atom is 0.02% by weight, the total content of other non-metallic heteroatoms (phosphorus atom and sulfur atom) except nitrogen atom and oxygen atom is 0.01% by weight, and the total content of metal atom The content is 0.1% by weight, and the weight loss rate in the temperature range of 400-800°C is w 800 , the weight loss rate w in the temperature range of 400-500°C 500 ,w 500 / w 800 0.12, purchased from Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences) dispersed in deionized water, and dispersed under ultrasonic oscillation conditions, the ultrasonic oscillation conditions include: the frequency is 140 kHz, and the time is 1 hour. Then, add barium hydroxide as the basic metal compound and nickel nitrate as the metal nitrate salt, thereby obtain the water dispersion liquid, wherein, according to the raw m...

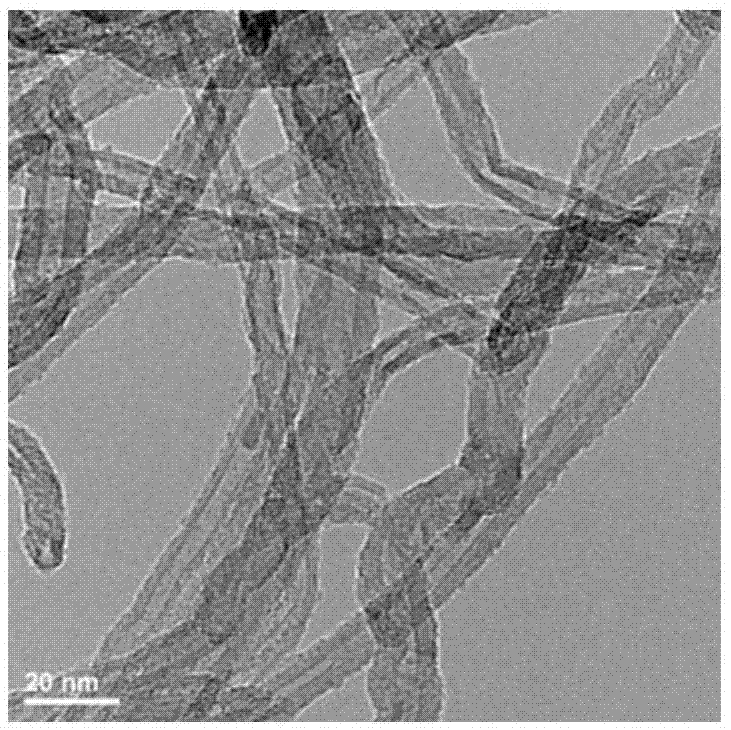

Embodiment 2

[0111] The same method as in Example 1 is used to prepare nano-carbon materials containing metal atoms. The difference is that in step (1), the ratio of multi-walled carbon nanotubes (purchased from Shandong Dazhan Nano Materials Co., Ltd.) as raw material nano-carbon materials Surface area is 251m 2 / g, the weight loss rate w in the temperature range of 400-800°C 800 , the weight loss rate w in the temperature range of 400-500°C 500 ,w 500 / w 800 is 0.33, the content of oxygen atoms is 0.62% by weight, the content of nitrogen atoms is 0.01% by weight, the total content of other non-metallic heteroatoms (phosphorus atoms and sulfur atoms) is 0.01% by weight except nitrogen atoms and oxygen atoms, and the total content of metal atoms is 0.01% by weight. The content is 0.08% by weight. The composition, specific surface area and w of the prepared metal atom-containing nanocarbon materials 500 / w 800 Listed in Table 1.

Embodiment 3

[0113] The same method as in Example 1 is used to prepare the metal-atom-containing nano-carbon material. The difference is that in step (2), the aqueous dispersion obtained is placed in an autoclave with a polytetrafluoroethylene liner at 80 °C under autogenous pressure for 24 hours. The composition, specific surface area and w of the prepared metal atom-containing nanocarbon materials 500 / w 800 Listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com