New energy automobile power drive system and active balancing method of battery capacity thereof

A new energy vehicle, electric drive technology, used in secondary battery charging/discharging, battery/fuel cell control devices, electric vehicles, etc. The effect of simplified management and active power balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

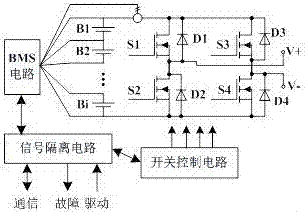

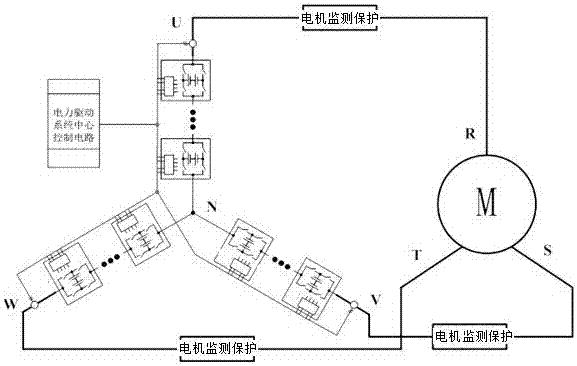

[0038] The system structure of the present invention sees figure 1 . The three module circuits are star-connected; each module circuit includes multiple modules in series; each module includes a battery pack and an inverter connected to the battery pack; the inverter is connected to the switch control circuit; all All the batteries in the battery pack are connected to the BMS circuit; the BMS circuit is connected to the switch control circuit through a signal isolation circuit; the signal isolation circuit is connected to the control center; the output ends of the three module circuits are respectively Corresponding connection with the three-phase stator winding of the motor.

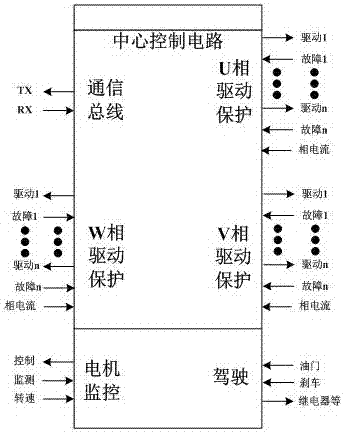

[0039] The motor-driven inverter has U, V, and W three-phase bridge arms (ie, module circuits), which are connected to the R, S, and T three-phase stator windings of the driven motor. Each phase bridge arm of the inverter is composed of n identical modules in series. Take the U-phase bridge arm as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com