Efficient synthesis method of acetyl tributyl citrate

A technology for acetyl tributyl citrate and tributyl citrate, which is applied in the field of efficient synthesis of acetyl tributyl citrate, can solve the problems of harsh catalyst synthesis conditions and low yield, and achieves high selectivity and yield. High, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

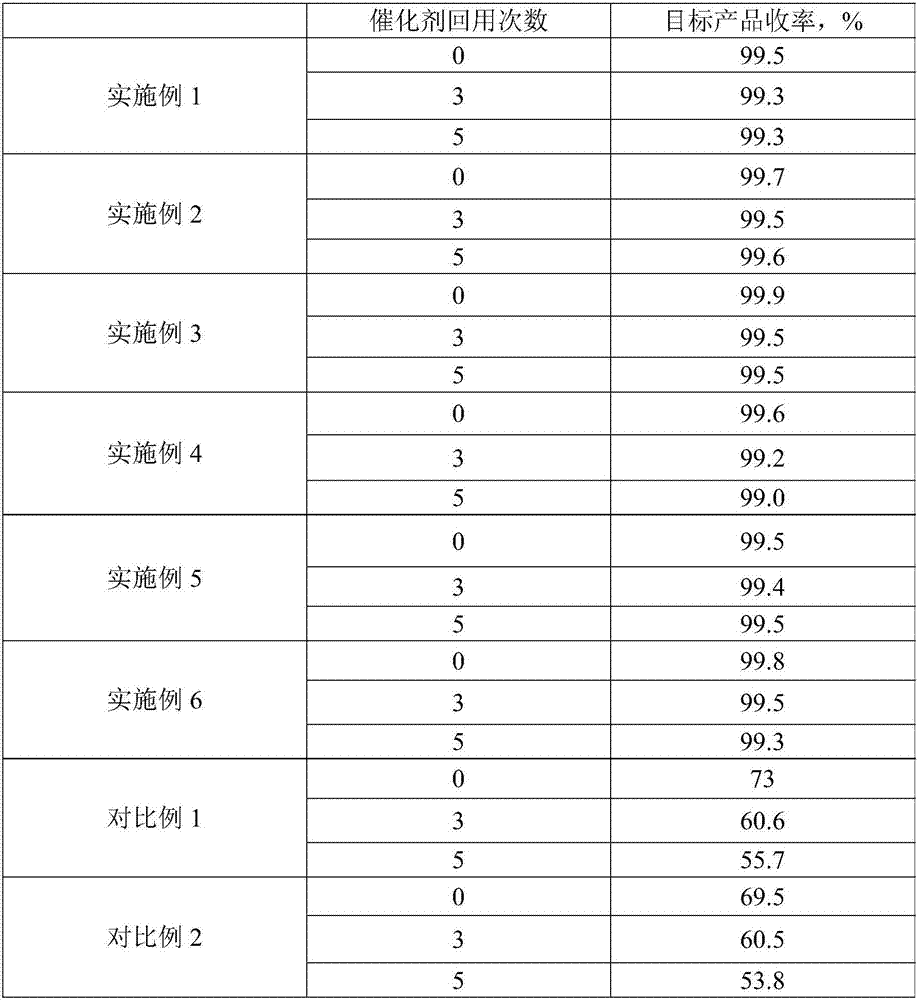

Examples

Embodiment 1

[0025] A kind of efficient synthetic method of acetyl tributyl citrate, comprises the following steps:

[0026] (1) mixing and stirring trifluoroacetic acid and concentrated sulfuric acid evenly to obtain a mixed acid catalyst; wherein, the content of fluoroacetic acid in the mixed acid catalyst is 10wt%;

[0027] (2) Stir tributyl citrate, n-butanol and acetic anhydride at room temperature for 10 minutes, then transfer to a three-necked flask, add the mixed acid catalyst prepared above, and react for 3 hours at 55° C. After the reaction, cool to At room temperature, remove the catalyst by filtration, cool the filtrate to room temperature after vacuum distillation, and wash with 8% sodium bicarbonate solution to neutrality, separate the organic phase, dry the organic phase with anhydrous copper sulfate, filter, and decompress the filtrate Distillation to obtain acetyl tributyl citrate; wherein, the mass ratio of tributyl citrate, n-butanol and acetic anhydride is: 1:2:1; the a...

Embodiment 2

[0029] A kind of efficient synthetic method of acetyl tributyl citrate, comprises the following steps:

[0030] (1) Trichloroacetic acid and concentrated sulfuric acid are mixed and stirred uniformly to obtain a mixed acid catalyst; wherein, the content of trichloroacetic acid in the mixed acid catalyst is 33wt%;

[0031] (2) Stir tributyl citrate, n-butanol and acetic anhydride at room temperature for 20 minutes, then transfer to a three-necked flask, add the mixed acid catalyst prepared above, and react for 1.5 hours at 95°C. After the reaction, cool to room temperature, remove the catalyst by filtration, cool to room temperature after the filtrate is distilled under reduced pressure, and wash to neutrality with a sodium bicarbonate solution with a mass fraction of 8%, separate the organic phase, dry the organic phase with anhydrous copper sulfate, filter, and the filtrate reduces Press distillation to obtain acetyl tributyl citrate; wherein, the mass ratio of tributyl citra...

Embodiment 3

[0033] A kind of efficient synthetic method of acetyl tributyl citrate, comprises the following steps:

[0034] (1) Mix and stir trifluoroacetic acid, trichloroacetic acid and concentrated sulfuric acid evenly to obtain a mixed acid catalyst; wherein, the content of trifluoroacetic acid and trichloroacetic acid in the mixed acid catalyst is 7wt%, 8wt%;

[0035] (2) Stir tributyl citrate, n-butanol and acetic anhydride at room temperature for 10 minutes, then transfer to a three-necked flask, add the mixed acid catalyst prepared above, and react at 60°C for 2.7 hours. After the reaction, cool to room temperature, remove the catalyst by filtration, cool to room temperature after the filtrate is distilled under reduced pressure, and wash to neutrality with a sodium bicarbonate solution with a mass fraction of 8%, separate the organic phase, dry the organic phase with anhydrous copper sulfate, filter, and the filtrate reduces Press distillation to obtain acetyl tributyl citrate; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com