Ultraviolet light excited three-component white light fluorescent powder and preparation method thereof

A three-component, ultraviolet light technology, applied in the field of white light phosphors, can solve the problems of being unsuitable for large-scale popularization and application, complicated preparation methods, etc., and achieve the effects of mature reaction conditions, simple preparation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

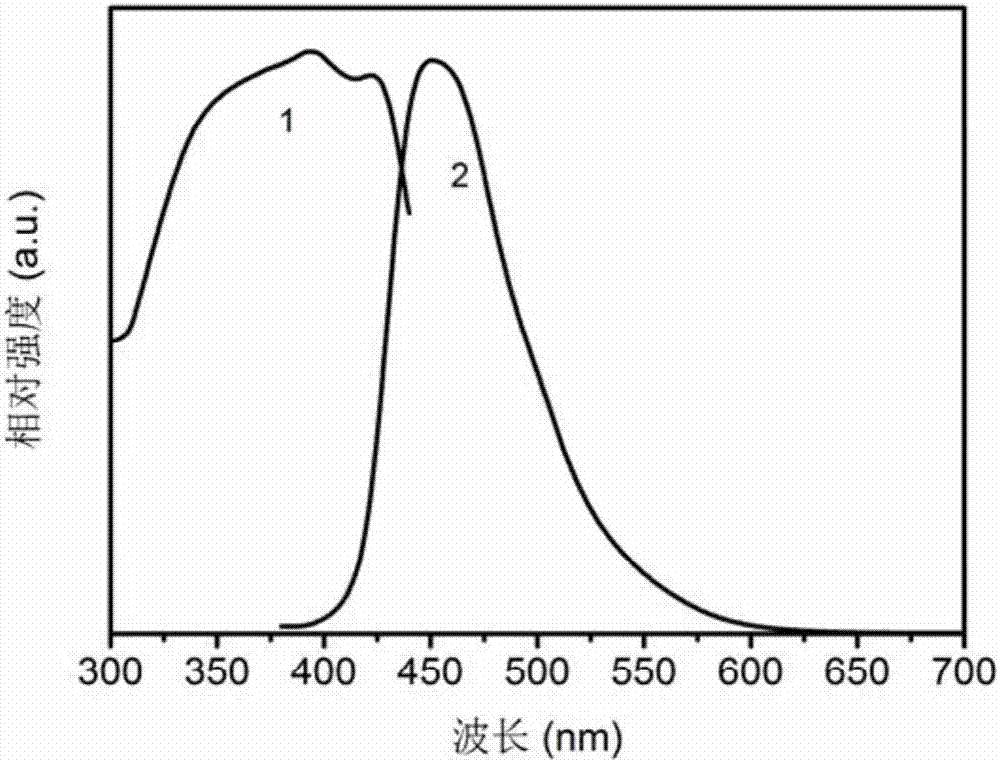

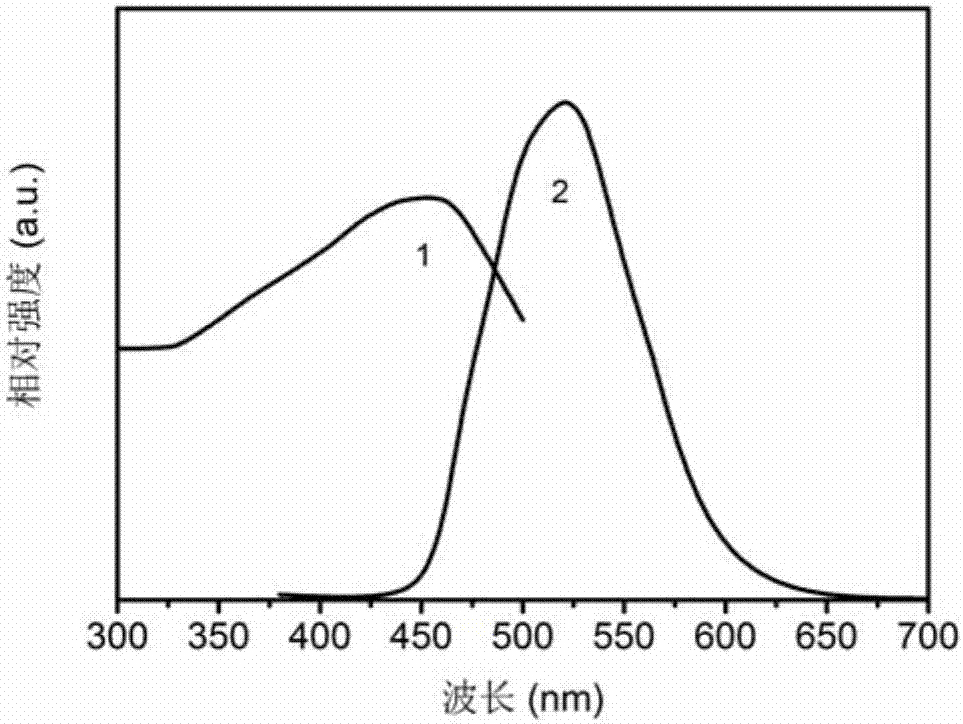

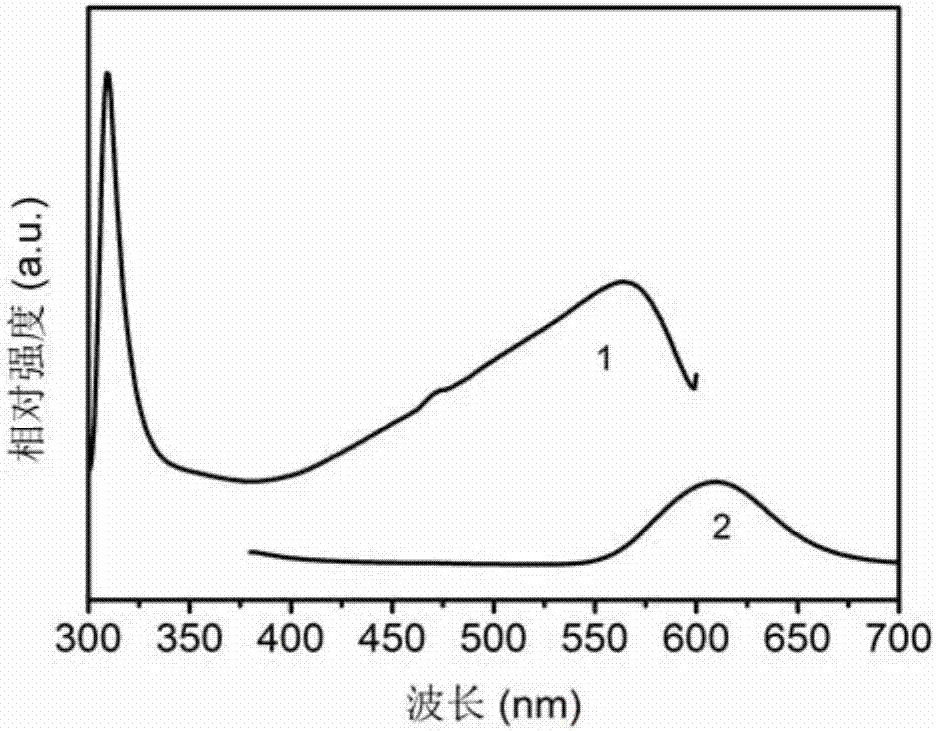

[0046] (1) Preparation of blue phosphor

[0047] 1) Weigh 10g of dicyandiamide and place it in a clean ceramic crucible, wrap it with aluminum foil and move it to a muffle furnace, and calcine it in air at 520°C for 2h, with a heating rate of preferably 3°C / min; after calcination, cool naturally to At room temperature, a light yellow blocky solid was obtained, which was collected by grinding with an agate mortar to obtain 5.2 g of light yellow powder g-C 3 N 4 .

[0048] 2) Take 2g g-C 3 N4 Put it into 50mL of concentrated nitric acid with a concentration of 65%, heat and stir at 80°C for 2 hours, the light yellow powder gradually turns white, after the reaction is completed, let it stand and cool to room temperature; collect the white powder by centrifugation, and wash the white powder with deionized water After many times, move it into a vacuum drying oven to dry at 60°C for 12 hours, grind and collect the white powder, that is, the blue phosphor, which is denoted as ACN....

Embodiment 2

[0063] (1) Preparation of blue phosphor

[0064] 1) Weigh 10g of dicyandiamide and place it in a clean ceramic crucible, wrap it with aluminum foil and move it to a muffle furnace, and calcine it in air at 500°C for 4h, with a heating rate of preferably 2°C / min; after calcination, cool naturally to At room temperature, a light yellow blocky solid was obtained, which was collected by grinding with an agate mortar to obtain 5.2 g of light yellow powder g-C 3 N 4 .

[0065] 2) Take 2g g-C 3 N 4 Put it into 50mL of concentrated nitric acid with a concentration of 65%, heat and stir at 80°C for 6h, the light yellow powder gradually turns white, after the reaction, let stand and cool to room temperature; collect the white powder by centrifugation, wash the white powder with deionized water After many times, move it into a vacuum drying oven to dry at 60°C for 12 hours, grind and collect the white powder, that is, the blue phosphor, which is denoted as ACN.

[0066] (2) Preparat...

Embodiment 3

[0077] (1) Preparation of blue phosphor

[0078] 1) Weigh 10g of dicyandiamide and place it in a clean ceramic crucible, wrap it with aluminum foil and move it to a muffle furnace, and calcine it in the air at 550°C for 2h, the heating rate is preferably 5°C / min; after the calcination, cool naturally to At room temperature, a light yellow blocky solid was obtained, which was collected by grinding with an agate mortar to obtain 5.2 g of light yellow powder g-C 3 N 4 .

[0079] 2) Take 2g g-C 3 N 4 Put it into 50mL of concentrated nitric acid with a concentration of 65%, heat and stir at 25°C for 1h, the light yellow powder gradually turns white, after the reaction, let it stand and cool to room temperature; collect the white powder by centrifugation, and wash the white powder with deionized water After many times, move it into a vacuum drying oven to dry at 60°C for 12 hours, grind and collect the white powder, that is, the blue phosphor, which is denoted as ACN.

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com