Method for recycling lithium from waste ternary lithium ion battery

A lithium-ion battery, lithium recovery technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, to achieve the effect of expanding production, high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

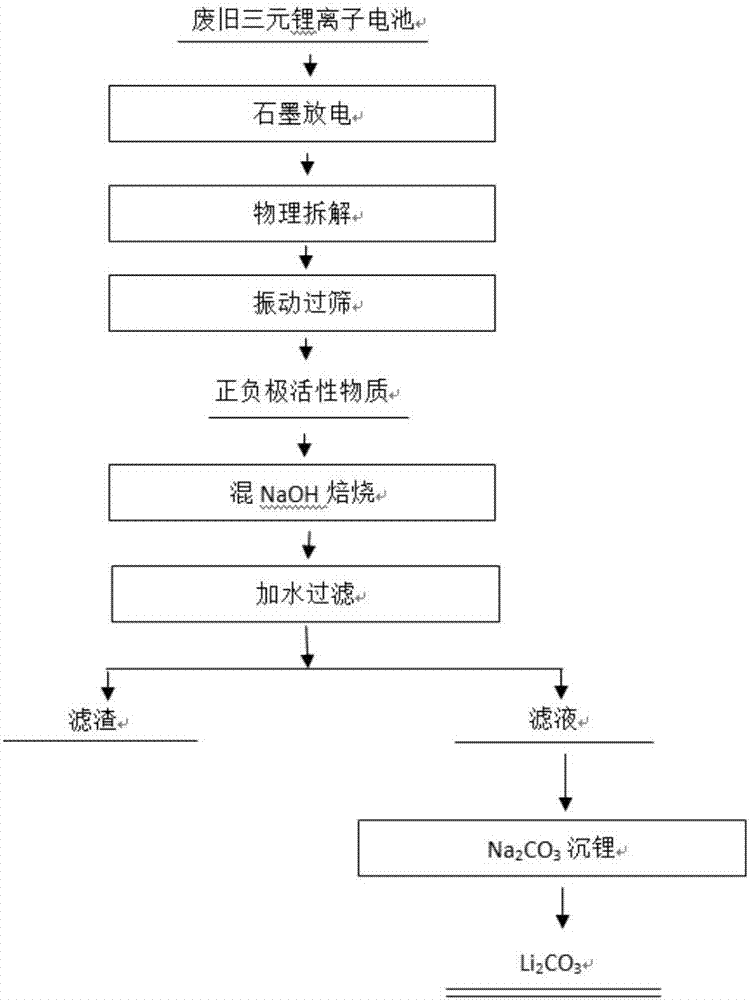

[0036] A method for reclaiming lithium from waste and old ternary lithium-ion battery active materials, comprising the following steps:

[0037] (1) Assembled and scrapped LiNi in the laboratory 1 / 3 co 1 / 3 mn 1 / 3 o 2 Place in graphite-containing solid powder and discharge for 12 hours, then disassemble and vibrate to obtain mixed powder of positive and negative active materials.

[0038] (2) Pass the mixed powder of positive and negative active materials through a 180-mesh sieve, and collect the sieved active material powder.

[0039] (3) Take 10g of the positive and negative active material mixed powder and mix them evenly with 5g of NaOH powder;

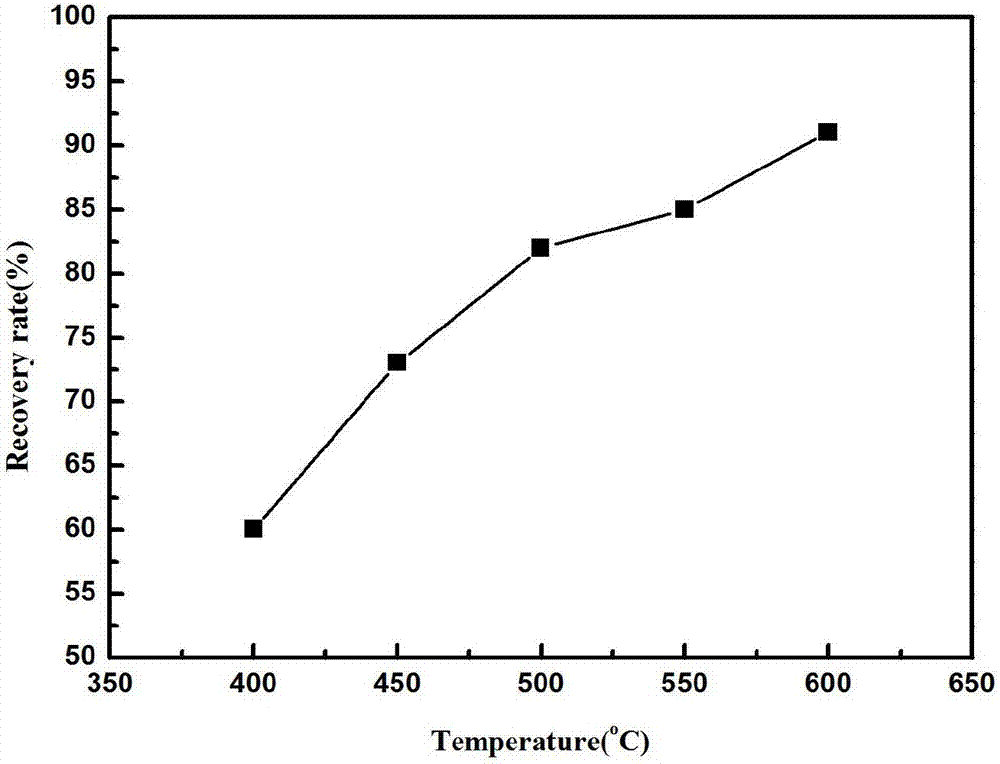

[0040] (4) Roasting the mixed powder of the active material and NaOH at 500°C for 4h;

[0041] (5) adding the roasted material into water and filtering;

[0042] (6) Add 0.5mol / L Na to the filtrate 2 CO 3 Solution, if there is precipitation, stir thoroughly for a period of time until no new precipitation is formed;

[0043...

Embodiment 2

[0046] A method for reclaiming lithium from waste and old ternary lithium-ion battery active materials, comprising the following steps:

[0047] (1) The acquisition of the active substance is the same as in Example 1, and the mixed powder of the positive and negative active substances of 10g is mixed with 5g NaOH;

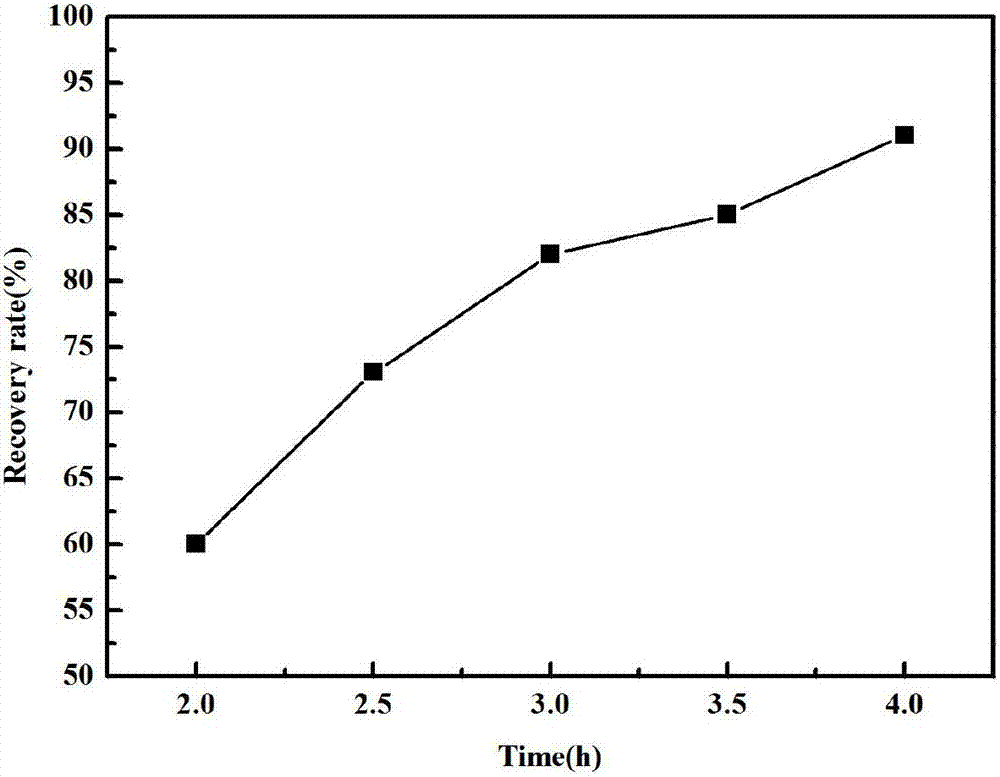

[0048] (2) Roasting the mixed powder of active material and NaOH at 500°C for 2h;

[0049] (3) adding the roasted material into water and filtering;

[0050] (4) Add 0.5mol / L Na to the filtrate2 CO 3 Solution, if there is precipitation, stir thoroughly for a period of time until no new precipitation is formed;

[0051] (5) Filter the suspension in (4), and the obtained filter cake is Li 2 CO 3

[0052] Adopt present embodiment to reclaim lithium recovery rate from waste and old ternary lithium ion battery as follows figure 1 As shown, it shows that after 10g of ternary battery active material powder is treated above, the recovery rate of lithium is 60.3%.

Embodiment 3

[0054] A method for reclaiming lithium from waste and old ternary lithium-ion battery active materials, comprising the following steps:

[0055] (1) The acquisition of the active substance is the same as in Example 1, and the mixed powder of the positive and negative active substances of 10g is mixed with 5g NaOH;

[0056] (2) Roasting the mixed powder of active material and NaOH at 600°C for 3h;

[0057] (3) adding the roasted material into water and filtering;

[0058] (4) Add 0.5mol / L Na to the filtrate 2 CO 3 Solution, if there is precipitation, stir thoroughly for a period of time until no new precipitation is formed;

[0059] (5) Filter the suspension in (4), and the obtained filter cake is Li 2 CO 3

[0060] Using this example to recover lithium from waste ternary lithium-ion batteries, it shows that after 10 g of ternary battery active material powder is treated above, the recovery rate of lithium is 82.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com