System for anodic oxidation reaction and electrolyte

A technology of anodic oxidation and electrolyte, applied in the direction of material analysis, measuring devices, instruments, etc. by electromagnetic means, can solve the problem that it is difficult to obtain high-quality surfaces that meet the requirements of optical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

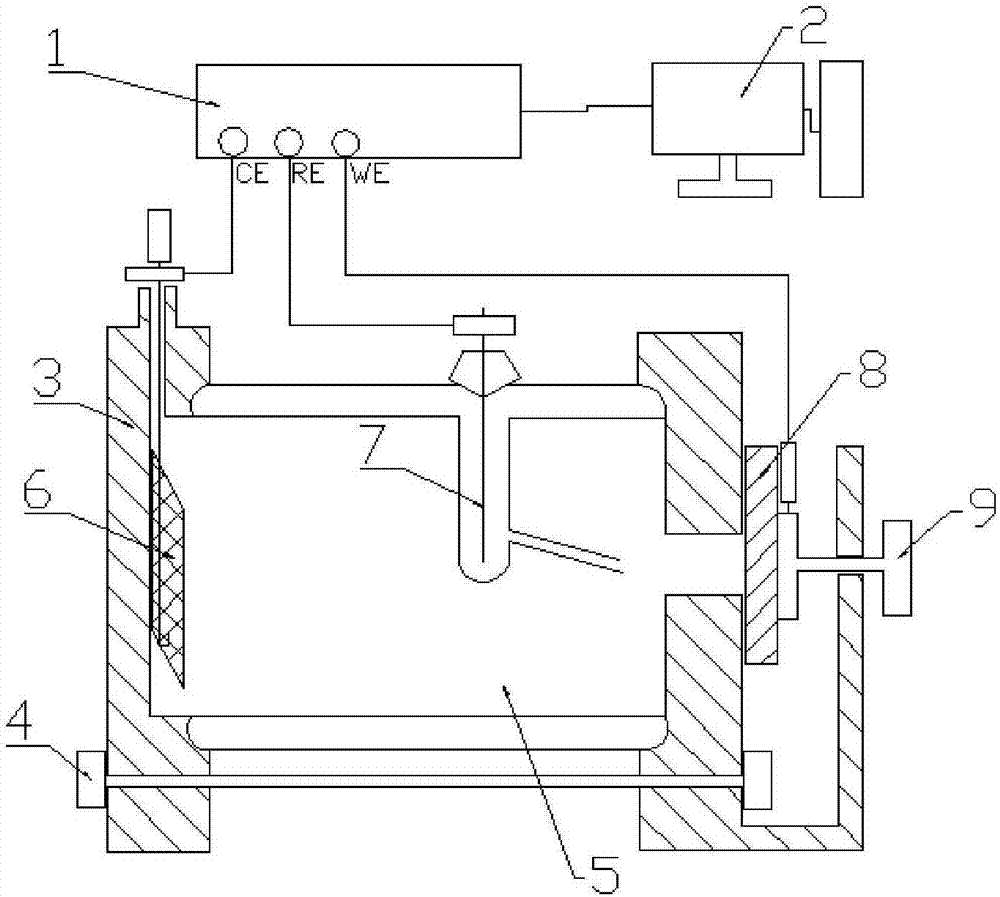

[0020] This embodiment provides a system for anodic oxidation reaction, the structure is as figure 1 As shown, the system includes a reaction vessel 3, the reaction vessel 3 is connected to a potentiostat 1, and the potentiostat 1 is connected to a computer 2; the reaction vessel 3 contains an electrolyte 5, and the electrolyte 5 is provided with a platinum grid electrode 6, and the platinum grid electrode 6 is connected to the auxiliary electrode of the potentiostat 1, the reference electrode 7 of the potentiostat 1 is immersed in the electrolyte 5, and the working electrode of the potentiostat 1 is connected to the sample 8.

[0021] A reaction vessel holder 4 is installed below the aforementioned reaction vessel 3 . The aforementioned sample 8 is installed and fixed on the side wall of the reaction vessel 3 through the sample holder 9 , and the sample 8 is in contact with the electrolyte 5 . The aforementioned reference electrode 7 adopts Ag or AgCl. The aforementioned sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com