Preparation and application for Ni-Co oxide catalyst prepared on basis of water-in-oil reverse microemulsion method

A reverse-phase microemulsion and water-in-oil technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low production efficiency, uneven particle size, and affecting catalytic performance of nano-scale materials, and achieve good ORR catalytic activity And reaction stability, simple preparation method, easy to popularize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

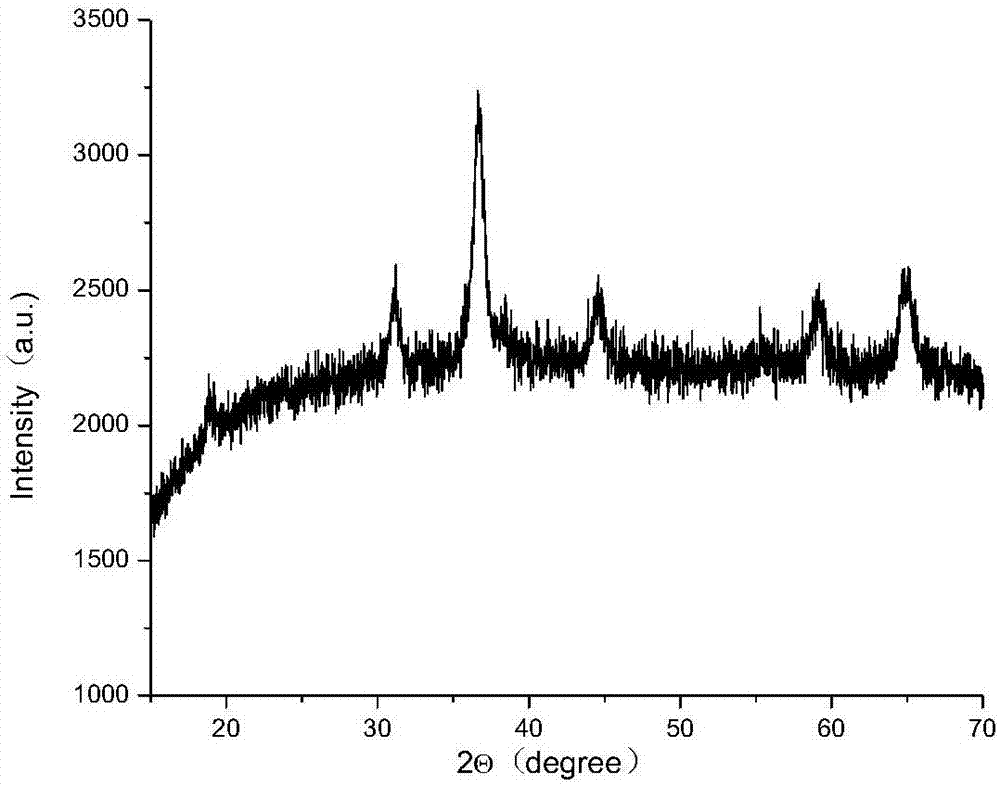

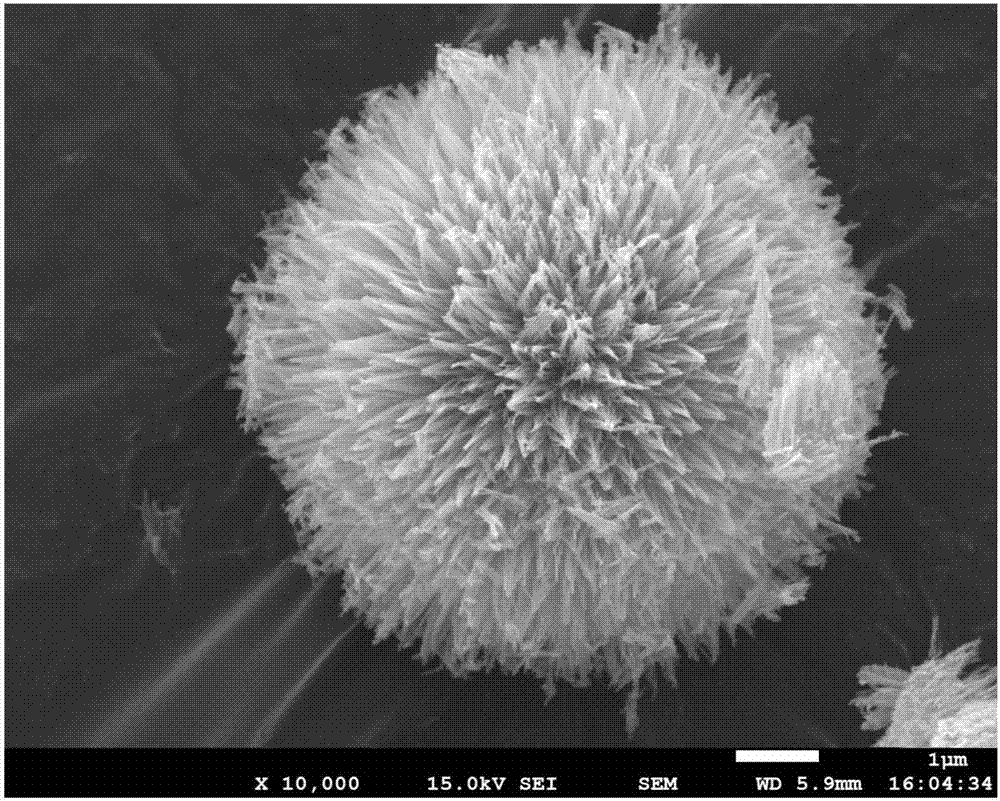

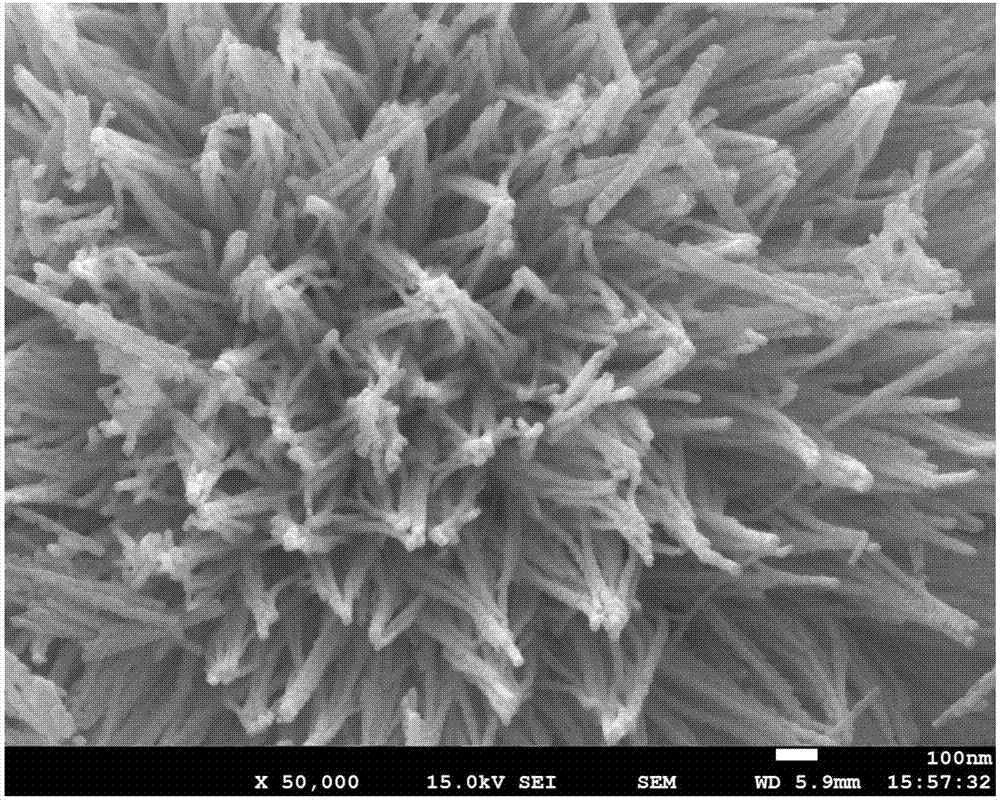

Embodiment 1

[0062] Prepare A solution, weigh 0.5mmol Ni(NO 3 ) 2 , 1mmol Co(NO 3 ) 2 , then add 3ml cyclohexane, 4.66mL DDAB (concentration: 2mmol / L), 2.34mL n-butanol, add water dropwise and stir for 0.5h until the solution is clear and transparent. To prepare solution B, add 3ml cyclohexane, 4.66mL DDAB (concentration: 2mmol / L), 2.34mL n-butanol, add ammonia water to adjust the pH to 9-10, and stir for 0.5h. Then mix the two solutions well, add ammonia water to adjust the pH to 9-10. From transparent to opaque. After stirring for half an hour, pour it into a reaction kettle and heat it at 60°C for 24 hours, then take it out, centrifuge and wash it, and vacuum freeze-dry it for 24 hours. Next, put it into a tube furnace for roasting, raise the temperature to 300°C in the air and keep it for 3h, and the heating rate is 5°C / min. Finally, the sea urchin-like nanostructured NiCo 2 o 4 , the quality is about 0.253g, and the productive rate is 89.3%, and the NiCo of productive rate (%)...

Embodiment 2

[0069] Prepare A solution, weigh 0.5mmol Ni(NO 3 ) 2 , 1mmol Co(NO 3 ) 2 , then added 4ml cyclohexane, 4mL DDAB (concentration: 4mmol / L), 2mL n-butanol, added water dropwise and stirred for 0.5h until the solution was clear and transparent. To prepare solution B, add 4ml cyclohexane, 4mL DDAB (concentration: 4mmol / L), 2mL n-butanol, add ammonia water to adjust the pH to 9-10, and stir for 0.5h. Then mix the two solutions well, add ammonia water to adjust the pH to 9-10. From transparent to opaque. After stirring for half an hour, pour it into a reaction kettle, heat it at 80°C for 24 hours, take it out, centrifuge and wash it, and vacuum freeze-dry it for 12 hours. Then put it into a tube furnace for roasting, raise the temperature to 400°C in the air and keep it for 3h, the heating rate is 10°C / min. Finally, the sea urchin-like nanostructured NiCo 2 o 4 , the mass is about 0.232g, and the yield is 85%. Product appearance is identical with embodiment 1. The catalyst ...

Embodiment 3

[0071] Prepare A solution, weigh 1mmol Ni(NO 3 ) 2 , 2mmol Co(NO 3 ) 2 , add 3ml of n-hexane, 4.66mL of DDAB (concentration: 6mmol / L), 2.34mL of n-butanol, add water dropwise and stir for 0.5h until the solution is clear and transparent. To prepare solution B, add 3ml cyclohexane, 4.66mL DDAB (concentration: 6mmol / L), 2.34mL n-butanol, add ammonia water to adjust the pH to 9-10, and stir for 0.5h. Then mix the two solutions well, add ammonia water to adjust the pH to 9-10. From transparent to opaque. After stirring for half an hour, pour it into a reaction kettle and heat it at 60°C for 24 hours, then take it out, centrifuge and wash it, and vacuum freeze-dry it for 24 hours. Then put it into a tube furnace for roasting, raise the temperature to 500°C in the air and keep it for 2h, the heating rate is 10°C / min. Finally, the sea urchin-like nanostructured NiCo 2 o 4 , the mass is about 0.504g, and the yield is 85.6%. Product appearance is identical with embodiment 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com