Emulsion paint composition with special artistic effect, and preparation method and application thereof

A composition and emulsion technology, applied in latex paint, building structure, coating, etc., can solve the problems of complex construction, no functionality, and hardening of shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

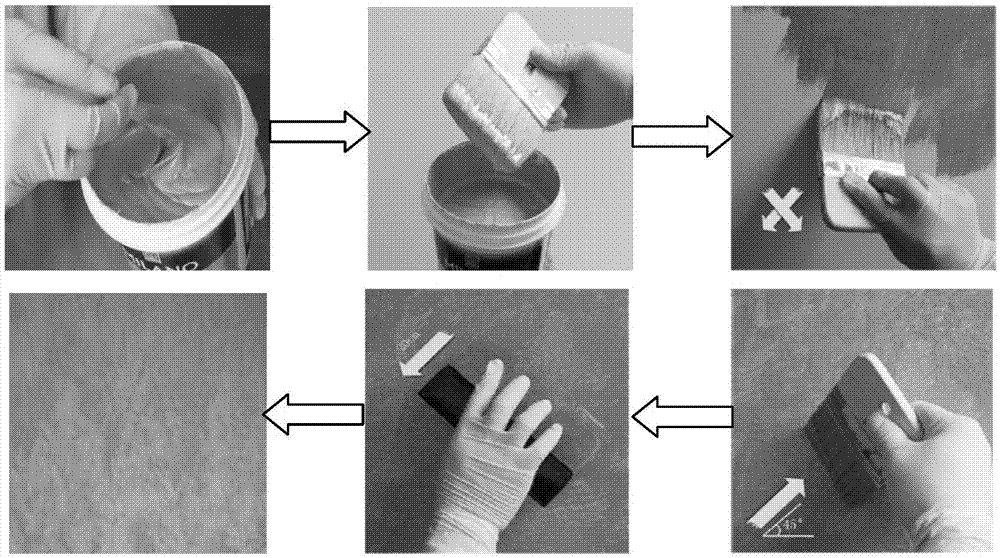

preparation example Construction

[0191] The present invention also provides a preparation method of the composition, comprising the steps of:

[0192] 1) providing the first mixed solution and the second mixed solution, wherein,

[0193] The first mixed solution contains: 3-30 parts by weight of pearlescent pigment, 20-25 parts by weight of glass beads and optionally 25-50 parts by weight of water;

[0194] The second mixed liquid contains: 10-40 parts by weight of emulsion;

[0195] 2) Mixing the first mixed liquid and the second mixed liquid under stirring condition to obtain the composition.

[0196] In another preferred example, the first mixed solution also contains one or more components selected from the following group:

[0197] 0.1-5 parts by weight of cellulose thickener;

[0198] The pH regulator of 0.01-1 weight part;

[0199] 0.01-1 part by weight of wetting agent;

[0200] 0.2-5 parts by weight of silicone defoamer; and

[0201] 0-10 parts by weight of antifreeze.

[0202] In another pref...

Embodiment 1

[0253] Example 1 Paint 1

[0254] making process

[0255] Weigh 18 parts of water in the tank by weight, add 10 parts of golden pearlescent pigments with a particle size of 10-60um (the outer layer of metal oxide is titanium dioxide and ferric oxide, and the particle size of the core mica is 7-40um) Soak for use, weigh 18 parts of water and add it to the dispersion tank, control the speed at 200-300 rpm, add in order: 0.75 part of cellulose thickener NATROSOL 250MBR, 0.1 part of organic alcohol amine pH regulator AMP950.1 part, 0.2 parts of wetting agent SN996, 3 parts of antifreeze PEG400, 0.3 parts of silicone defoamer SN154, 28 parts of pre-soaked pearlescent pigment slurry, 3 parts of 100-mesh glass beads, 17 parts of 150-mesh glass beads, and adjust the speed to 1000 rev / min, disperse for 15 minutes and then control the speed at 700-800 rev / min, add in sequence: 0.5 part of preservative BIOX CM, 0.5 part of antifungal agent BIOX M248, 25 parts of pure acrylic emulsion SF...

Embodiment 2

[0265] Example 2 Paint 2

[0266] making process

[0267] Take by weight 15 parts of water and the tank, add 10 parts of golden pearlescent pigments with a particle size of 10-60um (the metal oxide outer layer is titanium dioxide and ferric oxide, and the particle size of the core mica is 7-40um ) soaked for later use, weighed 16 parts of water and added to the dispersion tank, the speed was controlled at 200-300 rpm, and added in turn: 0.75 part of cellulose thickener NATROSOL 250MBR, 0.1 part of organic alcohol amine pH regulator AMP950.1 , 0.2 parts of wetting agent SN996, 3 parts of antifreeze PEG400, 0.3 parts of silicone defoamer SN154, 25 parts of pre-soaked pearlescent pigment slurry, 5 parts of 100-mesh glass beads, 20 parts of 150-mesh glass beads, adjust the speed to 1000 rpm, disperse for 15 minutes and then control the rotation speed at 700-800 rpm, add in sequence: 0.5 parts of preservative BIOX CM, 0.5 parts of antifungal agent BIOX M248, 25 parts of pure acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com