Method of producing functional nutritious food by using sorghum as a raw material

A nutritious food and functional technology, applied in the field of sorghum deep processing, can solve the problems of different efficacy, achieve the effect of increasing added value, strengthening practical value, and reducing starch digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] The specific embodiment one, in the present embodiment, the method for producing functional nutritious food with sorghum as raw material is carried out according to the following steps:

[0017] Step a, preparing sorghum starch and sorghum protein by using alkali-soluble acid precipitation method, weighing sorghum grains, soaking them in water for 5 hours, grinding and filtering with gauze, leaving the filtrate for 2 hours, and degreasing the obtained starch precipitation with petroleum ether, Wash 3 times with 1% NaCl, elute 3 times with 0.01M / L sodium hydroxide (collect the eluent for later use), then rinse with distilled water until the pH is neutral, and dry the precipitate at 40°C to obtain sorghum starch ; The pH of the eluate collected by eluting with sodium hydroxide is adjusted to 4.2, and the obtained precipitate is freeze-dried to obtain sorghum protein.

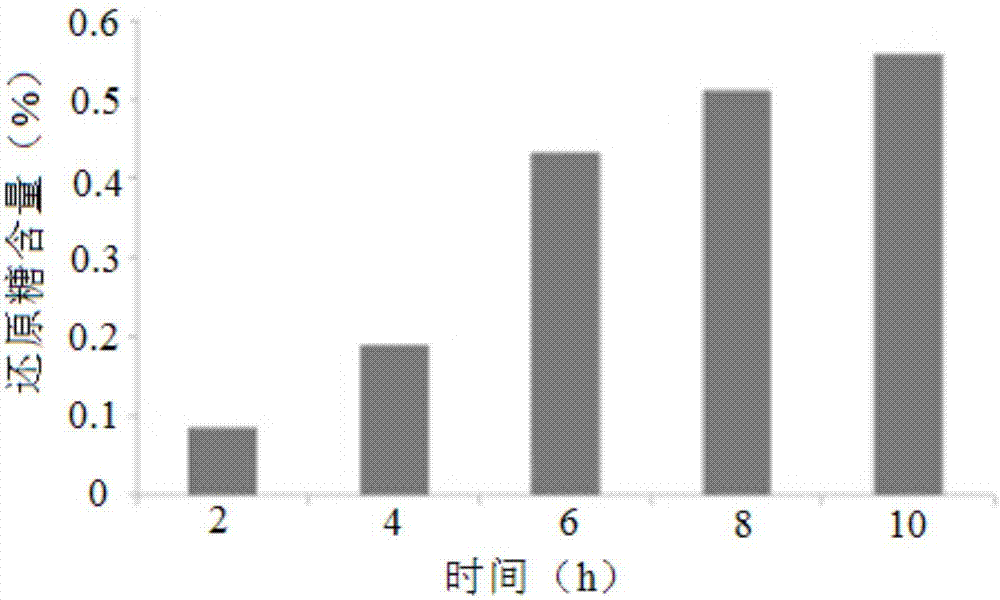

[0018] The sorghum starch obtained in step b and step a is formulated into 10% (w / v) starch milk, the pH...

specific Embodiment approach 2

[0025] Specific embodiment two, in the present embodiment, the method for producing functional nutritious food with sorghum as raw material is carried out according to the following steps:

[0026] In step a, the sorghum starch and sorghum protein are prepared by using an alkali-soluble acid precipitation method, and the preparation steps and parameters are the same as those in Embodiment 1;

[0027] The sorghum starch obtained in step b and step a is formulated into 15% (w / v) starch milk, the pH value is adjusted to 8.0, microwave gelatinization is carried out under the condition of microwave power of 320W for 2.0min, and it is placed in a refrigerator at 4°C for cooling for 42h. Drying at 35°C and pulverizing to obtain sorghum resistant starch;

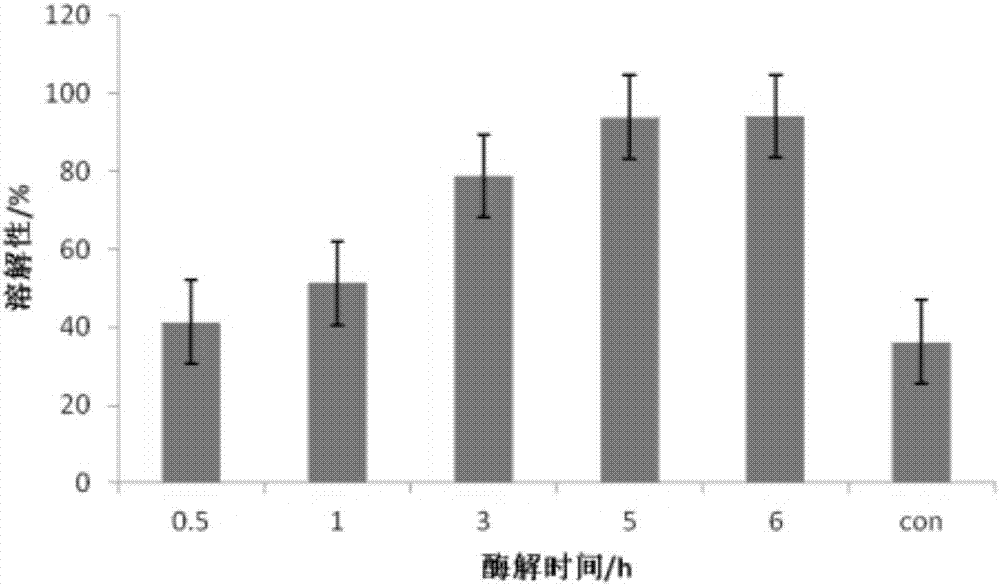

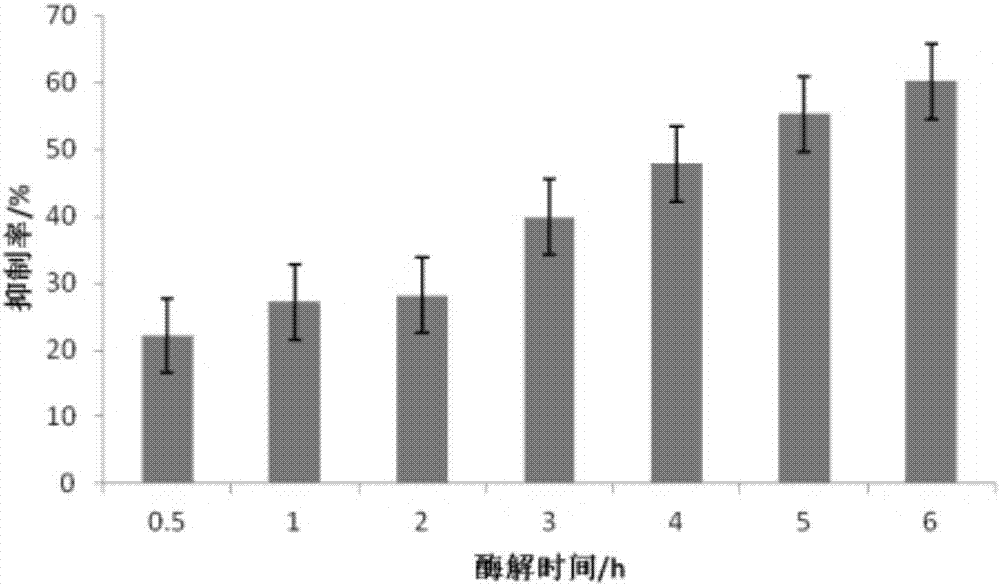

[0028] The sorghum protein obtained in step c and step a is prepared into a 12% (w / v) protein solution, preheated in a water bath at 95°C for 8 minutes, then sequentially use trypsin, alkaline protease, and flavor protease to perfor...

specific Embodiment approach 3

[0031] Specific embodiment three, in the present embodiment, the method for producing functional nutritious food with sorghum as raw material is carried out according to the following steps:

[0032]In step a, the sorghum starch and sorghum protein are prepared by using an alkali-soluble acid precipitation method, and the preparation steps and parameters are the same as those in Embodiment 1;

[0033] The sorghum starch obtained in step b and step a is formulated into 30% (w / v) starch milk, the pH value is adjusted to 9.0, microwave gelatinization is performed under the condition of microwave power of 240W for 2.0min, and it is placed in a refrigerator at 4°C for cooling for 48h. Drying at 35°C and pulverizing to obtain sorghum resistant starch;

[0034] The sorghum protein obtained in step c and step a is prepared into a 16% (w / v) protein solution, preheated in a water bath at 95°C for 10 minutes, then sequentially use trypsin, alkaline protease, and flavor protease for gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com