Phosphorus removal modified slag haycite and preparation method and application thereof

A phosphorus modification and steel slag technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of low phosphorus removal efficiency and complicated preparation methods, and achieve good adsorption effect, The effect of simple preparation method and wide industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

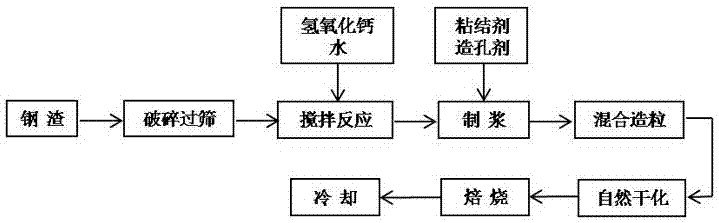

Method used

Image

Examples

Embodiment 1

[0033] Crush the steel slag to a fineness of 100-200 mesh, and dry it at 105°C to obtain steel slag powder. Mix 100-200 mesh steel slag powder with calcium hydroxide at a mass ratio of 5:1, add a certain amount of water to it, and place it in a constant temperature magnetic stirrer at 70°C for 4 hours to obtain calcium hydroxide-modified steel slag slurry material.

[0034] According to calcium hydroxide modified steel slag: montmorillonite powder: soluble starch mass ratio is 60%: 25%: 15%, add montmorillonite powder and soluble starch to calcium hydroxide modified steel slag slurry, stir evenly, get Mix slurry.

[0035] The above mixed slurry is granulated and casted to make particles with a particle size of 3~5mm, and the particles are dried under natural conditions for 24 hours, and then the obtained particles are put into a muffle furnace and calcined in an air atmosphere at 1100°C After 30 minutes, it was taken out after natural cooling to obtain steel slag ceramsite m...

Embodiment 2

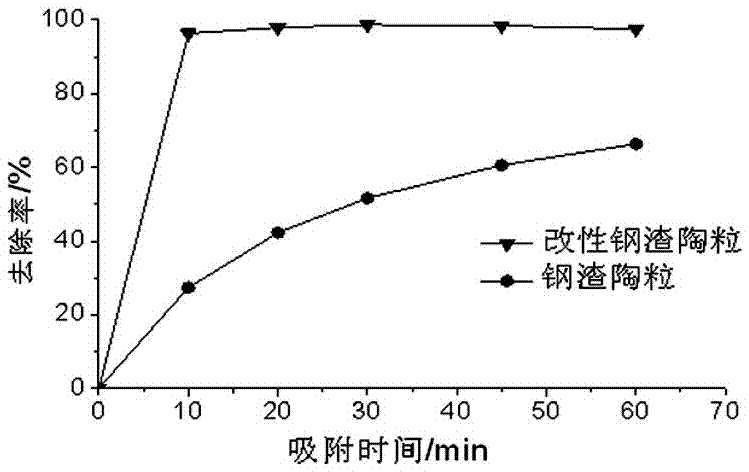

[0039] 100 mL of KH with an initial concentration of 0.5 mg / L 2 PO 4 The solution (calculated as P) is packed into a 250mL series conical flask with a stopper, and the pH value of the solution is adjusted to neutrality by using 5% hydrochloric acid and 5% sodium hydroxide, and the adsorbent amount prepared in Example 1 of 5g / L is added respectively. Calcium hydroxide modified steel slag ceramsite or steel slag ceramsite prepared in Comparative Example 1 and 0.5g toluene (as microbial inhibitor), 3 parallel experiments for each group. Place the Erlenmeyer flask in a shaker at 25°C and 150r / min for 1 hour. During this period, take samples every 10 min, 20 min, 30 min, 45 min, and 60 min. Take the supernatant and filter it with a 0.45 μm filter membrane. Filter, and measure the concentration of residual phosphate in the filtrate after filtration. The phosphorus removal experiment results of the modified steel slag ceramsite prepared in Example 1 and the steel slag ceramsite pre...

Embodiment 3

[0042] Crush the steel slag to a fineness of 100-200 mesh, and dry it at 105°C to obtain steel slag powder. Mix 100-200 mesh steel slag powder and calcium hydroxide at a mass ratio of 3:1, add a certain amount of water to it and place it in a constant temperature magnetic stirrer at 70°C for 4 hours to obtain calcium hydroxide-modified steel slag slurry material.

[0043] According to calcium hydroxide modified steel slag: montmorillonite powder: soluble starch mass ratio is 80%: 15%: 5%, add montmorillonite powder and soluble starch to calcium hydroxide modified steel slag slurry, stir evenly, get Mix slurry.

[0044] The above mixed slurry is granulated and casted to make particles with a particle size of 3~5mm, and the particles are dried under natural conditions for 24 hours, and then the obtained particles are put into a muffle furnace and calcined at 1300°C in an air atmosphere After 15 minutes, take it out after natural cooling to obtain steel slag ceramsite modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com