Preparation method of bimetallic loaded graphene catalyst for electrochemical detection of chlorophenol pollutants

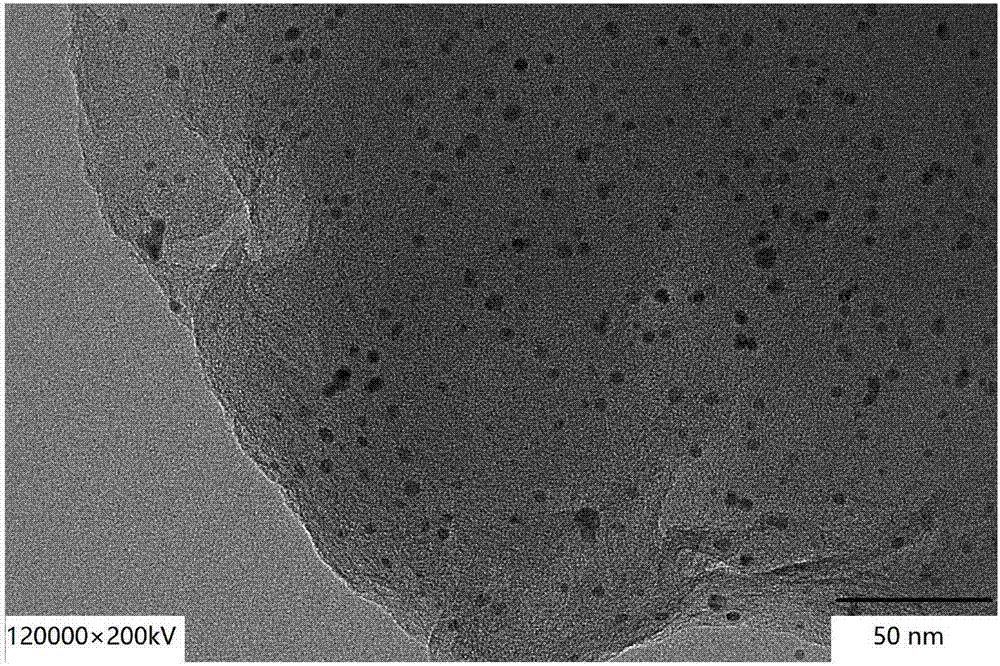

A bimetal and graphene technology, applied in the field of environmental pollutant detection, can solve the problems such as difficulty in controlling the particle size of silver-supported graphene catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Graphite oxide was prepared by the improved Hummers method. 0.2 g of graphite oxide was dispersed in 200 mL of deionized water, and ultrasonically treated for 2 h to obtain a graphite oxide solution (1.0 mg / mL). Dissolve 0.4g of polyvinylpyrrolidone in 100mL of 1% ethanol to prepare a 4% PVP dispersant solution, add 8mL of 4% PVP dispersant solution to the graphite oxide solution dropwise, and stir vigorously for 10-30min to oxidize Graphite and PVP are mixed evenly. Get 20mg palladium nitrate and dissolve in 10% nitric acid of 100mL, configure the palladium nitrate metal precursor solution of 0.2g / L, get the above-mentioned 0.2g / L palladium nitrate precursor solution of 12.5mL and join in the above-mentioned mixed solution, stir vigorously for 10 After ~30min, add 30% ammonia water dropwise, and adjust the pH of the mixture to 8~12; take 0.2g of silver nitrate and dissolve it in 1000mL of water to prepare a 0.2g / L silver nitrate metal precursor, and mix 8mL of 0.2g / L ...

Embodiment 2

[0026] This example is similar to the steps of Example 1, except that the amount of the metal precursor solution added is different: take 20 mg of palladium nitrate and dissolve it in 100 mL of 10% nitric acid to prepare a 0.2 g / L palladium nitrate metal precursor solution, and take 25 mL of The above 0.2g / L palladium nitrate precursor solution was added to the mixed solution described in Example 1, and after vigorous stirring for 10-30min, the pH was adjusted to 8-12; 0.2g silver nitrate was dissolved in 1000mL water, and 0.2g / L silver nitrate metal precursor solution, 16mL of 0.2g / L silver nitrate solution was added to the mixed solution, then continued to stir for 2h and mixed evenly, then reduced according to the reduction method in Example 1. The theoretical loading ratio of silver-palladium bimetallic elements in the prepared catalyst is 1:1.

Embodiment 3

[0028]This example is similar to the steps in Example 1, except that the amount of metal precursor solution added is different: take 25mL of 0.2g / L palladium nitrate precursor solution and add it to the mixed solution described in Example 1, and stir vigorously for 10-30min Finally, adjust the pH to 8-12; add 32mL of 0.2g / L silver nitrate solution into the mixture, then continue to stir for 2h to mix evenly and then reduce according to the reduction method in Example 1. The theoretical loading ratio of silver-palladium bimetallic elements in the prepared catalyst is 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com