Chromium-doped magnetite hetero-phase Fenton catalyst and preparation method for same

A catalyst and magnetite technology, which is applied in the field of chromium-doped magnetite heterogeneous Fenton catalyst and its preparation, can solve the problems of unsatisfactory decolorization and degradation effects of anionic dyes, neglect of the influence of catalytic oxidation effects, etc., and achieve the realization of Reuse, good degradation effect, high removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

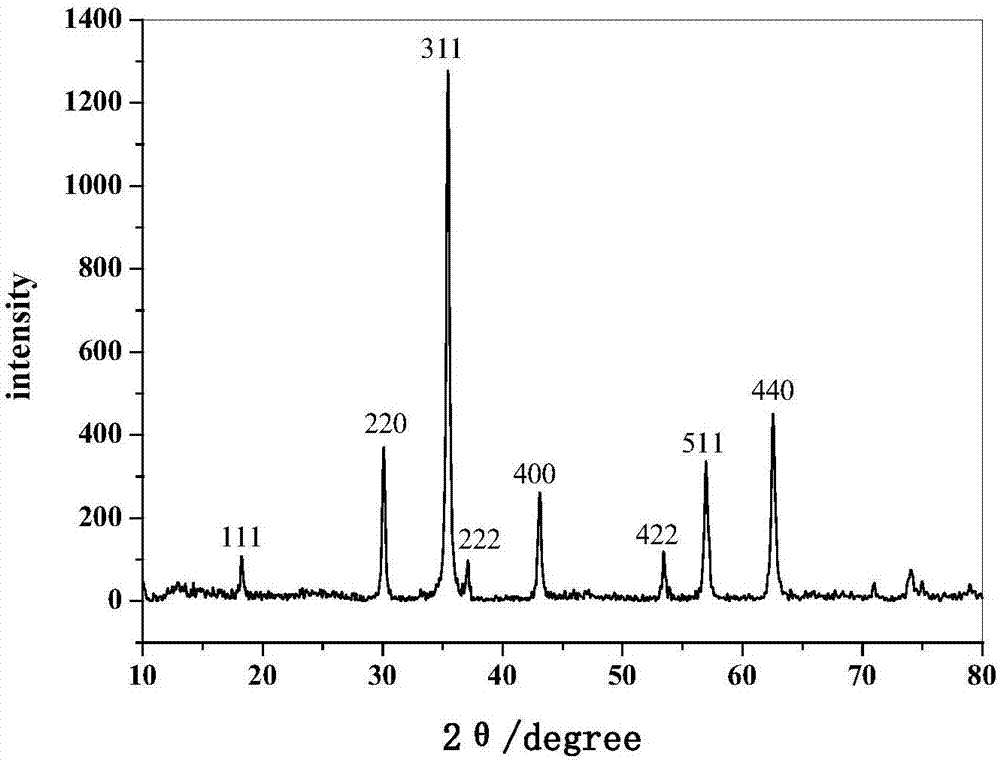

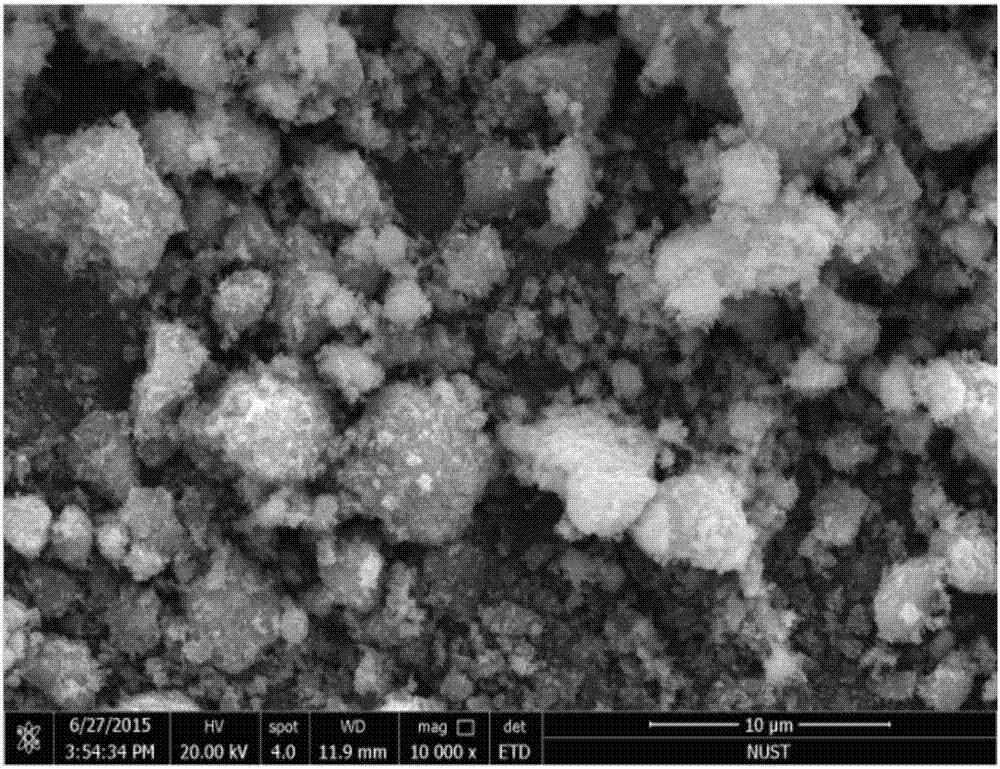

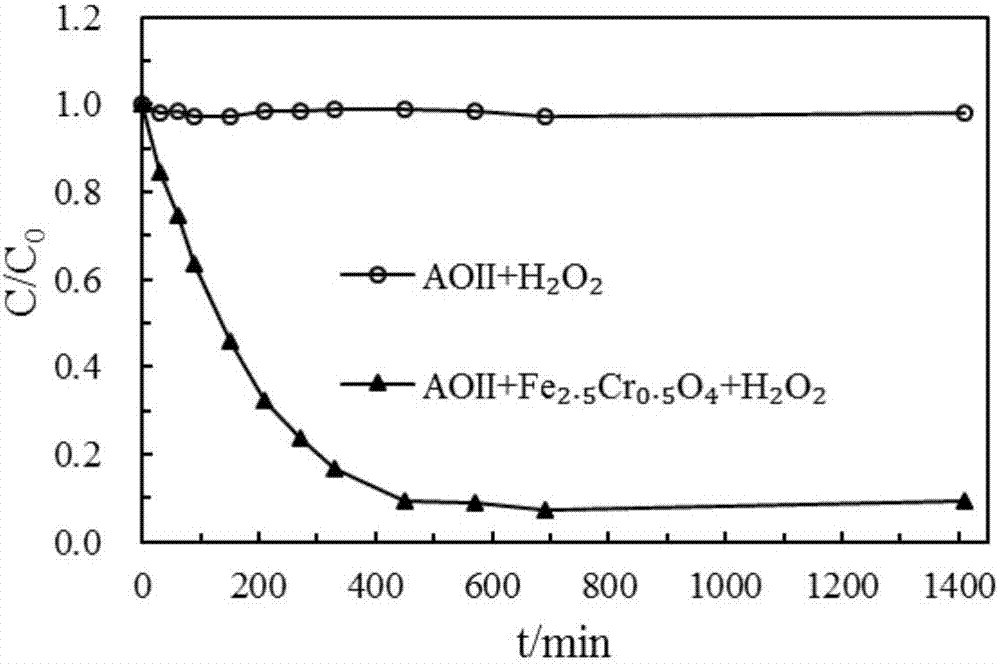

[0020] Example: Fe 2.5 Cr 0.5 o 4 Preparation and decolorization of Acid Orange II:

[0021] According to Fe 2+ :Cr 3+ Take 0.05 mol of ferrous sulfate heptahydrate and 0.01 mol of chromium nitrate nonahydrate at a molar ratio of 2.5:0.5 and mix them with 200 mL of deionized water. The metal ion concentration in the mixed solution is about 0.3 mol / L. Take 50mL of NH with a mass concentration of 25.0-28.0% 3 ·H 2 O was diluted with an equal volume of deionized water, and the above metal ion mixture was quickly poured into ammonia water, and the reaction system was stirred and reacted at a speed of 800r / min for 2h. After the stirring reaction was completed, Fe was separated by centrifugation 2.5 Cr 0.5 o 4 , washed, and centrifuged again. After repeated operation 5 times, dry at 100°C for 12h. After the dried sample is cooled, the sample is ground to 40-60 mesh, and placed in a muffle furnace for calcination at 400°C for 3 hours to obtain chromium-doped magnetite Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com