Wastewater nitrogen removal treatment system and nitrogen removal treatment process

A treatment system and waste water technology, applied in multi-stage water treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve problems such as difficult water discharge, standard discharge, high nitrogen content, etc., and achieve good removal and pH value maintenance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

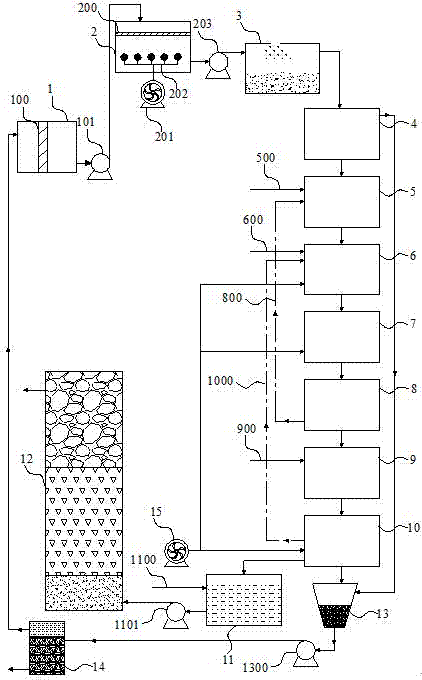

[0033] Such as figure 1 As shown, a waste water denitrification treatment system includes a sump tank 1, an aeration tank 2, a coagulation tank 3, an air flotation tank 4, an MBR tank, a reuse pool 11 and a sulfur iron filter bed 12 connected in series through pipelines in sequence. A coarse grid 100 is provided in the sump 1, a 1# pump 101 is provided on the pipeline between the sump 1 and the aeration tank 2, and a fine grid 200 is provided in the aeration tank 2, and the specification of the coarse grid is 40mm, the specification of the fine grid is 8mm, the aeration tank 2 is provided with an aeration pipe 202 and the aeration pipe 202 is connected to the 1# blower 201. The pipeline between the aeration tank 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com