A kind of preparation method of 5-fluorouracil spherical crystal

A technology of fluorouracil and spherical crystals, which is applied in the field of preparation of 5-fluorouracil spherical crystals, can solve problems such as solvent or reagent residue, and achieve the effects of increasing shear force and breaking force, reducing aggregation efficiency, and large wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of 5-fluorouracil spherical crystal of the present invention, this preparation method comprises the following steps:

[0029] (1) Add 5-fluorouracil and purified water solvent into a cylindrical reactor, and heat to 90-100°C under stirring to prepare a 5-fluorouracil solution;

[0030] (2) Decrease the temperature and crystallize the 5-fluorouracil solution in the step (1) at a stirring speed of 140-280rpm, and adopt a gradient cooling method to cool down for 4-5h;

[0031] (3) The temperature of the system is lowered to below 35° C. for filtration, and the filter cake is dried under normal pressure at 70-80° C. for 3-4 hours. After drying to constant weight, spherical crystals of 5-fluorouracil are obtained.

[0032] Among the present invention, the more specific implementation mode as an example is: the consumption of the purified water solvent in the step (1) is 10-15 times of 5-fluorouracil, and the stirring in the step (1) adopts a turbine ty...

Embodiment 1

[0035] Add 3kg of 5-fluorouracil and 30kg of purified water (10 times the mass of 5-fluorouracil) into a clean 50L cylindrical reactor, stir with a turbine-type stirring paddle, heat the reaction system to 100°C, and dissolve the solid completely to obtain 5 - Aqueous solution of fluorouracil.

[0036] The temperature of the above solution was lowered at a rate of 0.2°C / min under stirring at 240rpm. At 93°C, solids began to precipitate. As the temperature decreased, the amount of solids precipitated increased.

[0037] Filter when the temperature of the solution drops to 25°C, and wash the filter cake with purified water. Drying at 70° C. under normal pressure for 4 hours gave about 2.71 kg of 5-fluorouracil spherical crystal product with a yield of 90.33%.

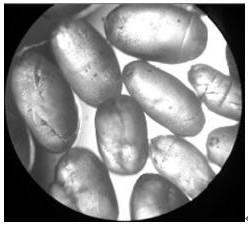

[0038] The microscope appearance picture of the obtained product is as follows: figure 1 As shown, the obtained crystal is a regular ellipsoid shape; D(0.9)=965 μm of the product, and the particle size distribution diag...

Embodiment 2

[0040] Add 1.6kg of 5-fluorouracil and 24kg of purified water (15 times the mass of 5-fluorouracil) into a clean 30L cylindrical reaction kettle, stir with an impeller-type stirring paddle, heat the reaction system to 95°C, and dissolve the solid completely to obtain 5-fluorouracil aqueous solution.

[0041] The temperature of the above solution was lowered at a rate of 0.3°C / min under stirring at 140rpm, solids began to precipitate at 90°C, and the amount of solids precipitated increased as the temperature decreased.

[0042] Filter when the temperature of the solution drops to 10°C, and wash the filter cake with purified water. After drying at 70°C under normal pressure for 4 hours, about 1.43 kg of spherical crystal product of 5-fluorouracil was obtained, with a yield of 89.37%.

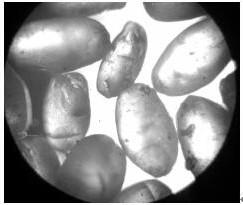

[0043] The microscope appearance picture of the obtained product is as follows: figure 2 As shown, the obtained crystal is a regular ellipsoid shape; the D(0.9)=921 μm of the product, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com