Activating agent for cobalt molybdenum catalyst and application

A technology of activators and catalysts, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that catalysts cannot contact with materials, hydrogenation reactions cannot occur, and avoid frequent replacement , Save equipment investment, save raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] An activator for a cobalt-molybdenum catalyst is composed of the following components by volume percentage:

[0033] Propane 0.4%

[0034] Propylene 1.2%

[0035] Isobutane 12%

[0036] n-Butane 26%

[0037] Trans-2-butene 17%

[0038] 1-Butene 16%

[0039] Isobutylene 15%

[0040] Cis-2-butene 12.3%

[0041] 1,3-Butadiene 0.1%

[0042] The cobalt-molybdenum catalyst is activated by using the activator with a good proportion above, and the reaction sequence is to raise the temperature first, and then introduce the new activator. The reaction pressure is 1.5Mpa, the hydrogen-oil ratio is 6, the volume space velocity is 4h-1, the inlet temperature is 160°C, the bed temperature is 220°C, the reaction time is 12h, and the amount of the new activator introduced is 2-4t / h.

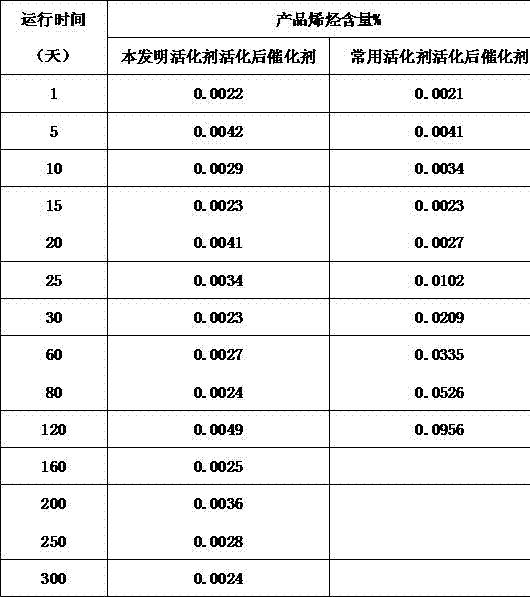

[0043] In order to verify the technical effect of the present invention, the inventor uses mixed carbon five (C5) fractions as raw materials, and the catalyst selects a Co-Mo hydrogenation catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com