Antimony-sulfur bulk concentrate flotation separation process and combined inhibitor

A combined inhibitor and mixed concentrate technology is applied in the flotation separation process of antimony-sulfur mixed concentrate and the combined inhibitor and mineral flotation reagent field, which can solve the problems of lack of efficient selective inhibitor in antimony-sulfur separation, etc. The effect of easy operation in industrial production, enhanced inhibition effect, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

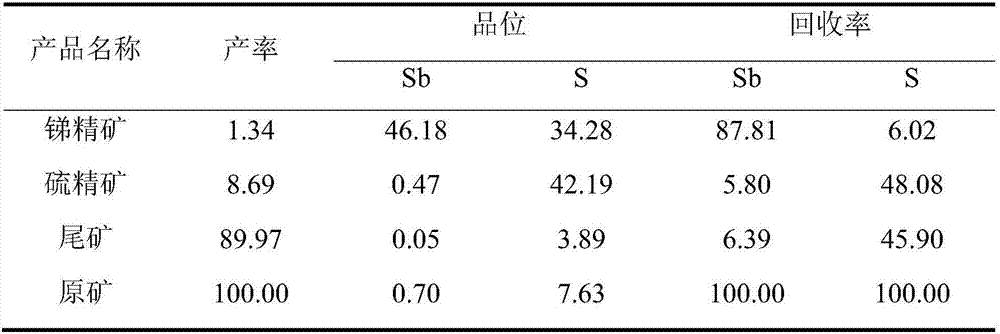

[0026] The antimony content in the test raw material (raw ore) is 0.71%, and the sulfur content is 7.89%. The technical mineralogy research results show that the main metal minerals of the ore are pyrite and stibnite. Adopt a kind of combined inhibitor for the separation of antimony and sulfur provided by the present invention and its application method, carry out laboratory small-scale closed-circuit test to this mine, the concrete steps of test are as follows:

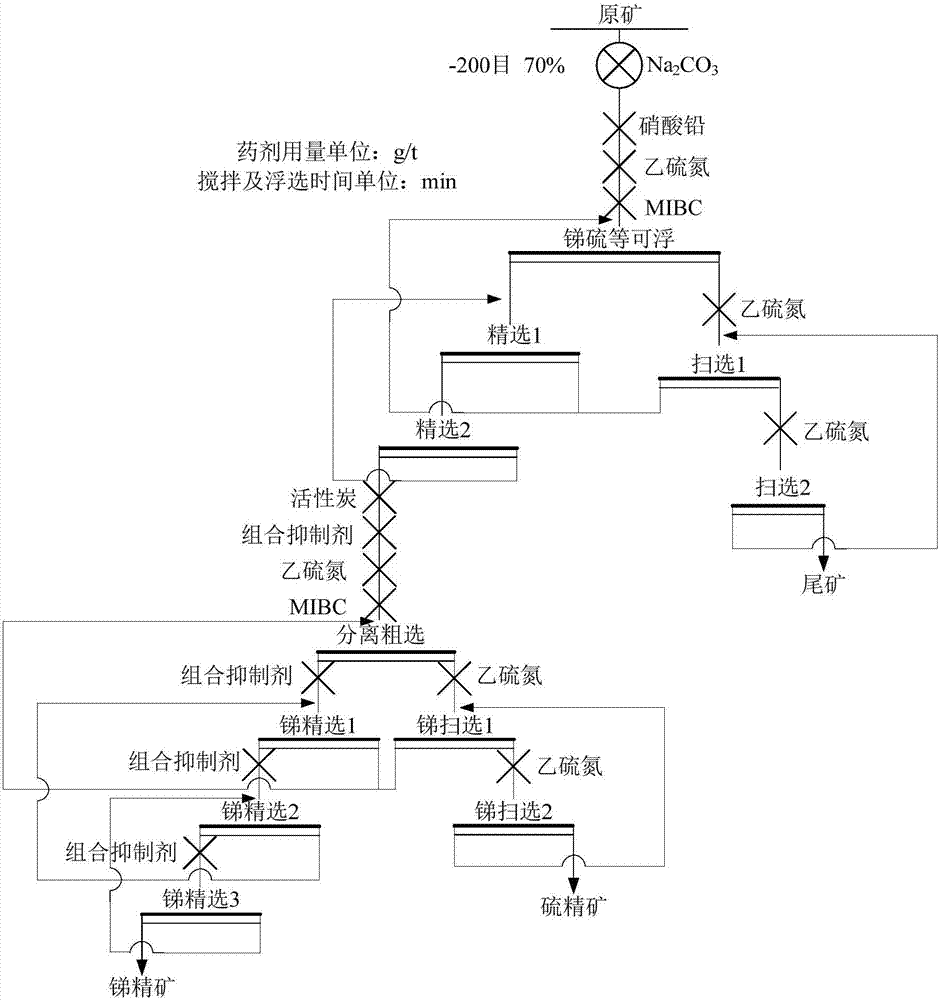

[0027] 1) Add 1000g / t of sodium carbonate during the ore grinding process until the fineness is -200 mesh 70%. After grinding, add 150g / t of lead nitrate as an activator and 15g / t of ethylsulfide as Collector, 20g / t of MIBC as foaming agent, stirring, antimony sulfur, etc. can be floated to obtain antimony sulfur mixed concentrate;

[0028] 2) During the flotation separation of antimony-sulfur mixed concentrate, first add 500g / t of activated carbon for drug removal, then add 50g / t of combined inhibitors as pyrite inh...

Embodiment 2

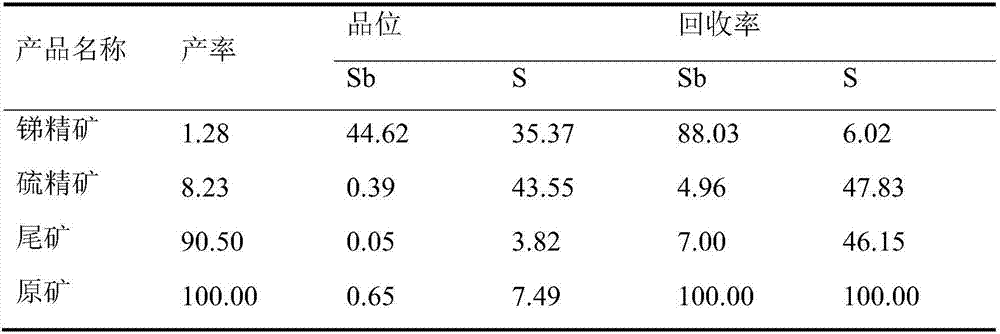

[0036] The content of antimony in the test raw material (raw ore) is 0.65%, and the content of sulfur is 7.51%. The results of technological mineralogy show that the main metal minerals of this mine are pyrite and stibnite. Adopt a kind of combined inhibitor for the separation of antimony and sulfur provided by the present invention and its application method, carry out laboratory small-scale closed-circuit test to this mine, the concrete steps of test are as follows:

[0037] 1) Add 1000g / t of sodium carbonate during the ore grinding process until the fineness is -200 mesh 70%. After grinding, add 120g / t of lead nitrate as an activator and 15g / t of ethylsulfide as a Collector, 20g / t of MIBC as foaming agent, stirring, antimony sulfur, etc. can be floated to obtain antimony sulfur mixed concentrate;

[0038] 2) When flotation separation of antimony-sulfur mixed concentrate, first add 500g / t of activated carbon to remove the drug, then add 50g / t of combined inhibitor as pyrite ...

Embodiment 3

[0046] For the ore sample in Example 1, under the condition that the process structure and other medicament systems are kept constant, the combined inhibitor provided by the present invention is replaced by CMC, and the small-scale closed-circuit test in the laboratory is carried out to the mine. The specific steps of the test are as follows:

[0047] 1) Add 1000g / t of sodium carbonate during the ore grinding process, grind the ore until the fineness is -200 mesh 70%, add 150g / t of lead nitrate as an activator after grinding, and add 15g / t of ethyl disulfide as an activator Collector, 20g / t of MIBC as foaming agent, stirring, antimony sulfur, etc. can be floated to obtain antimony sulfur mixed concentrate;

[0048]2) During the flotation separation of antimony-sulfur mixed concentrate, first add 500g / t of activated carbon for drug removal, then add 200g / t of CMC (carboxymethyl cellulose) as pyrite inhibitor, and 5g / t of ethyl sulfur Nitrogen is used as a collector of stibnite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com