Method for reductively degrading triphenylmethane dye crystal violet wastewater quickly

A technology for triphenylmethane and dye wastewater, applied in energy wastewater treatment, general water supply conservation, chemical instruments and methods, etc., to achieve good degradation effect, strong environmental adaptability, and reduce equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

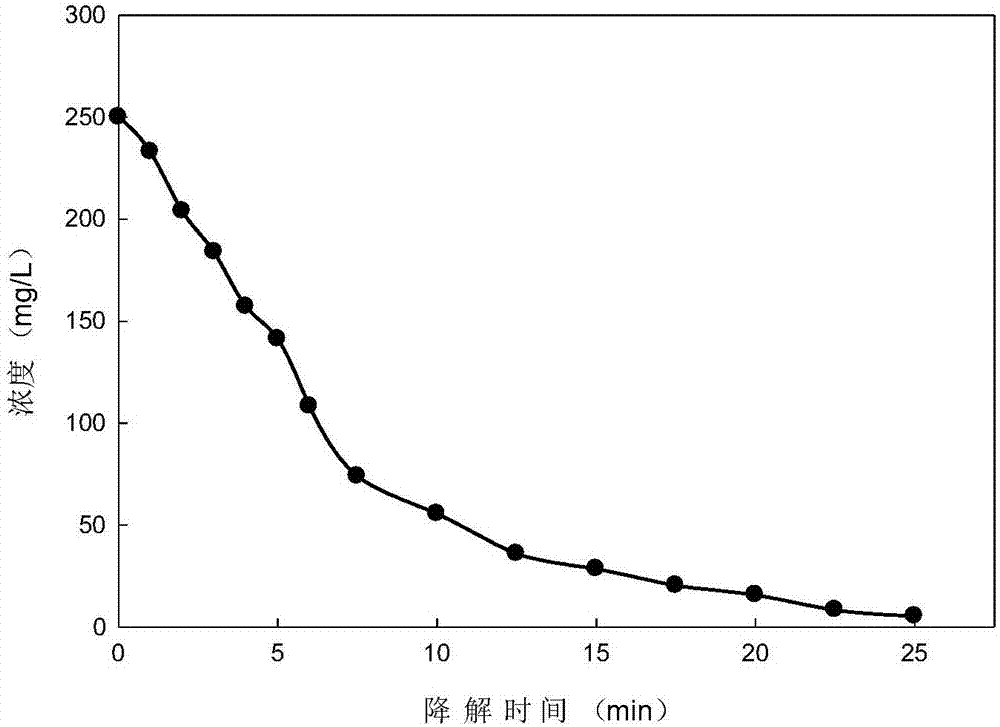

[0027] After pulverizing the perilla seeds dried in the sun for 2 hours, prepare perilla seed solution at 2 g / L standard, ultrasonicate for 15 min under the condition of ultrasonic power of 50 W, and filter with medium-speed filter paper to obtain the perilla seed extract. Seed extract is mixed with 100mL concentration of 0.1mol / L soluble ferrous salt solution with the mass fraction of 2%wt, with Fe 2+ :BH 4 - Under the condition that the molar ratio is 1:2, the borohydride solution is slowly added and stirred until no bubbles are generated, and the nano-zero-valent iron (perilla seed-nano-zero-valent iron) suspension modified on the surface of perilla seeds is obtained. At room temperature, add the perilla seed-nanometer zero-valent iron at a dose of 1 g / L to 100 mL, pH=2, and contain 250 mg / L triphenylmethane dye crystal violet wastewater, and shake to make the dye wastewater Discoloration, degradation.

[0028] In this example, perilla seed-nano zero-valent iron complete...

Embodiment 2

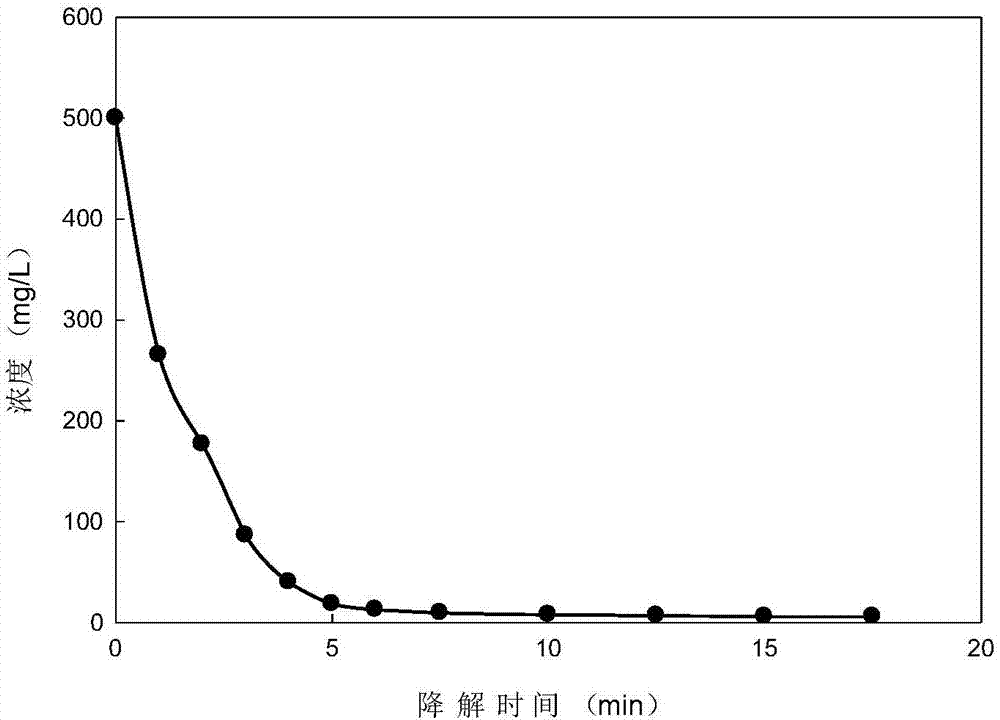

[0030] After pulverizing the perilla seeds dried in the sun for 2 hours, prepare perilla seed solution at 2 g / L standard, ultrasonicate for 15 min under the condition of ultrasonic power of 50 W, and filter with medium-speed filter paper to obtain the perilla seed extract. Seed extract is mixed with 100mL concentration of 0.1mol / L soluble ferrous salt solution with the mass fraction of 2%wt, with Fe 2+ :BH 4 -Under the condition that the molar ratio is 1:2, the borohydride solution is slowly added and stirred until no bubbles are generated, and the nano-zero-valent iron (perilla seed-nano-zero-valent iron) suspension modified on the surface of perilla seeds is obtained. At room temperature, add the perilla seed-nanometer zero-valent iron into 100mL, pH=4, crystal violet wastewater containing 500mg / L triphenylmethane dye at a dose of 1.5g / L, and shake to make the dye Wastewater decolorization and degradation.

[0031] In this example, the perilla seed-nano zero-valent iron c...

Embodiment 3

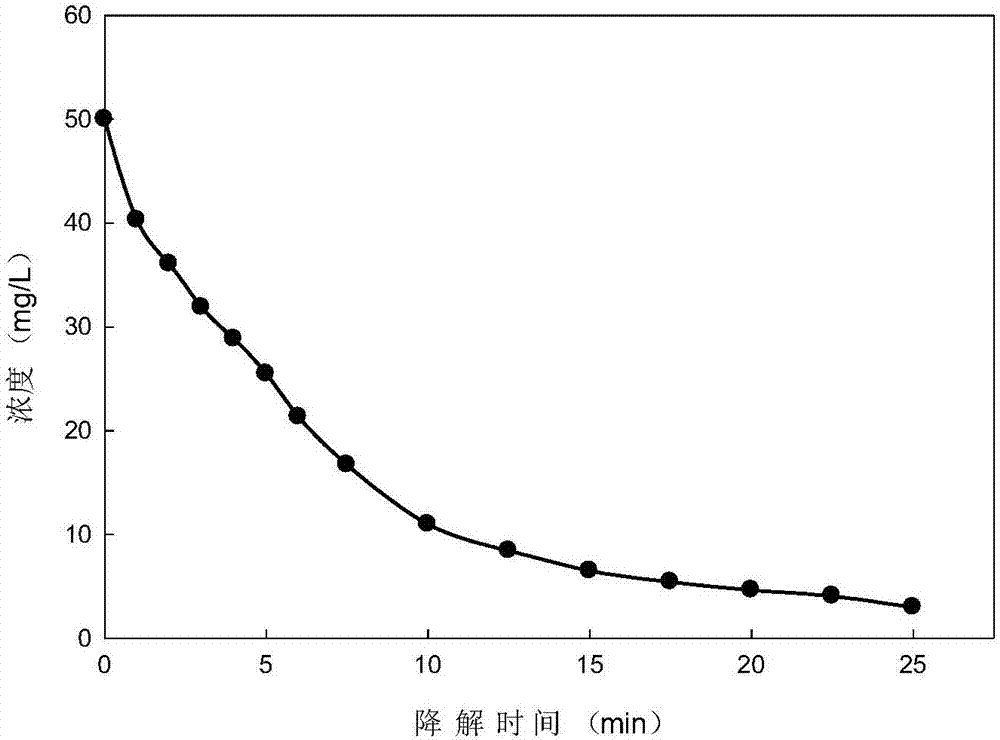

[0033] After pulverizing the perilla seeds dried in the sun for 2 hours, prepare perilla seed solution at 2 g / L standard, ultrasonicate for 15 min under the condition of ultrasonic power of 50 W, and filter with medium-speed filter paper to obtain the perilla seed extract. Seed extract is mixed with 100mL concentration of 0.1mol / L soluble ferrous salt solution with the mass fraction of 2%wt, with Fe 2+ :BH 4 - Under the condition that the molar ratio is 1:2, the borohydride solution is slowly added and stirred until no bubbles are generated, and the nano-zero-valent iron (perilla seed-nano-zero-valent iron) suspension modified on the surface of perilla seeds is obtained. At room temperature, add the perilla seed-nanometer zero-valent iron at a dose of 0.5g / L to 100mL, pH=6, and contain 50mg / L triphenylmethane dye crystal violet wastewater, and shake to make the dye Wastewater decolorization and degradation.

[0034] In this example, perilla seed-nano zero-valent iron comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com