Heat, electricity and fertilizer coproduction system and process for edible mushroom dreg

A technology of edible mushroom residue and thermoelectricity, which is applied in the direction of gasification process, application, petroleum industry, etc., can solve the problems of inability to realize the resource utilization of mushroom residue, abnormally serious non-point source pollution in rural areas, and deterioration of air environment quality, and achieve light bulk density , Heap specific gravity and energy density increase, the effect of low resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail.

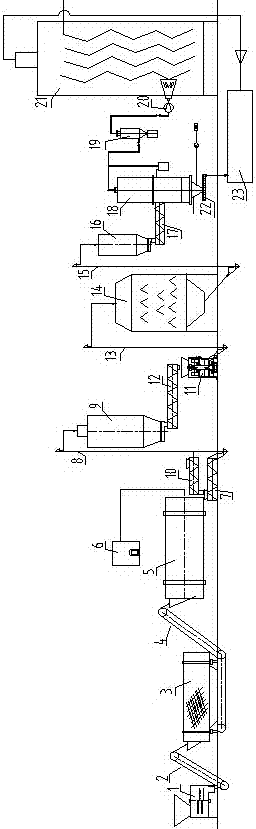

[0018] Such as figure 1 As shown, the edible fungus slag heat and electricity fertilizer cogeneration system of the present embodiment includes a bacteria bag crusher 1, a drum sieve sorter 3, a drum dryer 5, and a drum dryer that are connected in series through belt conveyors 2 and 4. The medium inlet of 5 is connected with the hot blast stove 6, the material outlet of the drum dryer 5 is connected with the rotary discharge bin 9 through the screw feeder 7 and the hoist 8, and the discharge port of an additive screw conveyor 10 is also connected with the screw The feeding port of the feeder 7 is connected, and the rotary unloading bin 9 is connected with the derivative fuel granulator 11 at the rear through a screw conveyor 12, and the derivative fuel granulator 11 is connected with the countercurrent cooler 14 through a hoist 13, The cooler 14 is connected to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com