A system and control method for automatically adding red mud to sintering mixture

A technology of sintering mixture and red mud, which is applied in the direction of flow control using electric devices, etc., which can solve the problems of increased porosity, affecting measurement accuracy, and deterioration of the particle size of the mixture, so as to achieve stable slurry concentration, ensure accuracy, and good The effect of uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following, the present invention will be further described through embodiments with reference to the accompanying drawings.

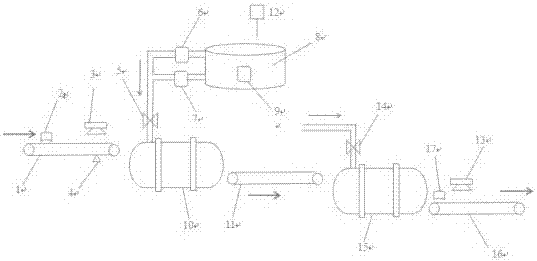

[0039] A system for automatically adding red mud to the sintering mixture, including a pre-mixing belt conveyor 1, a sizing device 2, a microwave moisture meter 3, a weighing scale 4, a red mud pipe cut-off valve 5, and a red mud main frequency conversion slurry pump 6. Red mud preparation frequency conversion slurry pump 7, red mud slurry pool 8, red mud mixer 9, primary mixer 10, belt conveyor 11 after one mixing, environmental thermometer 12, microwave moisture meter 13, regulating valve 14, The secondary mixer 15, the second mixing belt conveyor 16, the rear sizing device 17; the primary mixer 10 before the first mixing belt conveyor 1 is installed with the sizing device 2 and the microwave moisture meter 3 above, and the weighing scale 4 is installed below; red Mud pipe shut-off valve 5, red mud main frequency conversion slurry pump 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com