Hot and sour diced potatoes

A technology of diced potatoes, hot and sour, applied in the direction of food preservation, food ingredients as antimicrobial preservation, food ingredients as taste improvers, etc. The effect of enriching flavor and nutrients, enhancing gastrointestinal function, and increasing nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

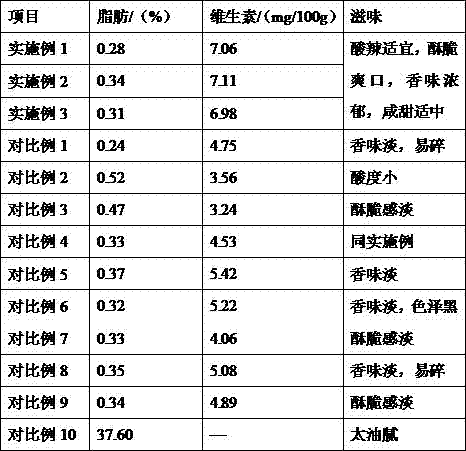

Examples

Embodiment 1

[0026] A hot and sour diced potato, made from the following parts by weight of raw materials: potato 63, corn flour 21, broad bean flour 12, lactic acid bacteria 3, Angel baker's yeast 3, seasoning 1.6, tuckahoe extract 0.7, white peony extract 0.7 , Vitamin C 0.04.

[0027] For the broad bean flour, the mature broad bean seeds are removed from the seed coat and placed in water. The amount of water added is 8 times the weight of the broad bean seeds, heated and boiled until the volume is 1 / 2 of the original size, the broad bean seeds are taken out, and the shells are removed. Put it into the water of boiled broad beans again, continue to heat until there is no obvious moisture, and continue to stir fry until the moisture content is 8-10%, and crush to 60 mesh to obtain broad bean flour.

[0028] The lactic acid bacteria are composed of the following strains by weight: Lactobacillus acidophilus 11, Lactobacillus delbrueckii 11, Lactobacillus bulgaricus 6, and Kefir 3.

[0029] The se...

Embodiment 2

[0045] A kind of hot and sour potato diced, made from the following raw materials in parts by weight: potato 64, corn flour 22, broad bean flour 13, lactic acid bacteria 4, Angel baker's yeast 4, seasoning 1.7, tuckahoe extract 0.8, white peony extract 0.8 , Vitamin C 0.05.

[0046] For the broad bean flour, the mature broad bean grains are removed from the seed coat and placed in water. The amount of water added is 9 times the weight of the broad bean grains, heated and boiled until the volume is 1 / 2 of the original volume. The broad bean grains are taken out, the shells are removed, and the broad bean kernels Put it in the water of boiled broad beans again, continue to heat until there is no obvious moisture, stir fry until the moisture content is 8-10%, crush to 60 mesh to obtain broad bean flour.

[0047] The lactic acid bacteria are composed of the following species by weight: Lactobacillus acidophilus 12, Lactobacillus delbrueckii 12, Lactobacillus bulgaricus 7, and Kefir 4. ...

Embodiment 3

[0053] A hot and sour potato diced, made from the following raw materials: potato 65, corn flour 23, broad bean flour 14, lactic acid bacteria 5, angel baker's yeast 5, seasoning 1.8, tuckahoe extract 0.9, white peony extract 0.9 , Vitamin C 0.06.

[0054] For the broad bean flour, the mature broad bean grains are removed from the seed coat and placed in water. The amount of water added is 10 times the weight of the broad bean grains, heated and boiled until the volume is 1 / 2 of the original volume, the broad bean grains are taken out, the shells are removed, and the broad bean kernels Put it in the water of boiled broad beans again, continue to heat until there is no obvious moisture, stir fry until the moisture content is 8-10%, crush to 80 mesh, and obtain broad bean flour.

[0055] The lactic acid bacteria are composed of the following species by weight: Lactobacillus acidophilus 13, Lactobacillus delbrueckii 13, Lactobacillus bulgaricus 8, Kefir 5.

[0056] The seasoning is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com