Method for treating waste water containing sulfate radical

A treatment method, technology containing sulfuric acid, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unpublished removal of sulfate radicals, high price, etc., to achieve optimal use, Easy to control and realize the effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

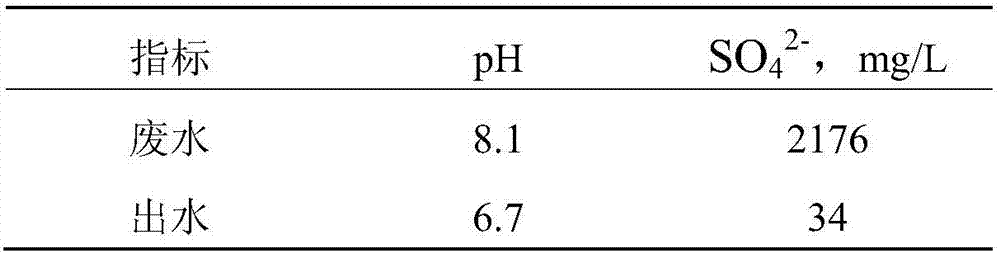

[0037] The sulfate-containing wastewater is wastewater from a dyeing factory, and the water quality is shown in Table 1:

[0038] Table 1 Dyeing plant wastewater and effluent quality after treatment

[0039]

[0040] Adjust the pH of wastewater to 4 to 10cm 2 The square lead plate is the anode, and the stainless steel of the same size is used as the cathode. The voltage is 5V and the current density is 0.25A / cm under the condition that the anode and cathode are directly opposite and the pole distance is kept 20cm. 2 Under electrolysis for 300 minutes, adjust the pH to 6.7, and the effluent water quality meets the discharge standard, see Table 1. SO in wastewater 4 2- The removal rate is 98.44%.

Embodiment 2

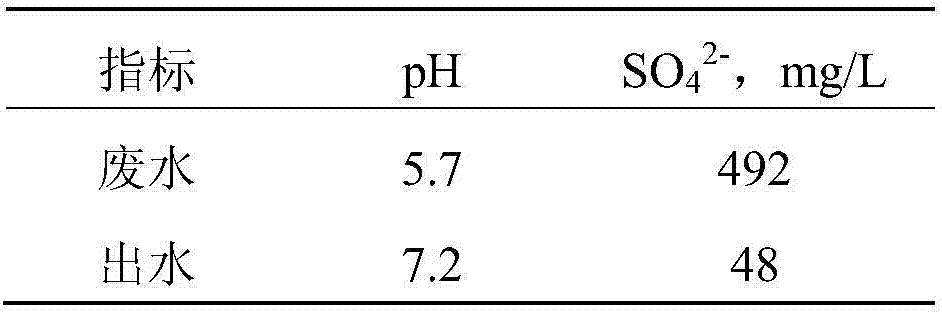

[0042] The sulfate wastewater is wastewater from a power plant, and the water quality is shown in Table 2:

[0043] Table 2 Power plant wastewater and effluent quality after treatment

[0044]

[0045] Adjust the pH of the wastewater to 4.5, to 20cm 2 The square lead plate is the anode, and the graphite plate of the same size is used as the cathode. The voltage is 3V and the current density is 0.4A / cm under the condition that the anode and the cathode are directly opposite and the pole distance is kept 10cm. 2 Under electrolysis for 60 minutes, adjust the pH to 7, and the effluent quality reaches the discharge standard, see Table 2. SO in wastewater 4 2- The removal rate is 90.24%.

Embodiment 3

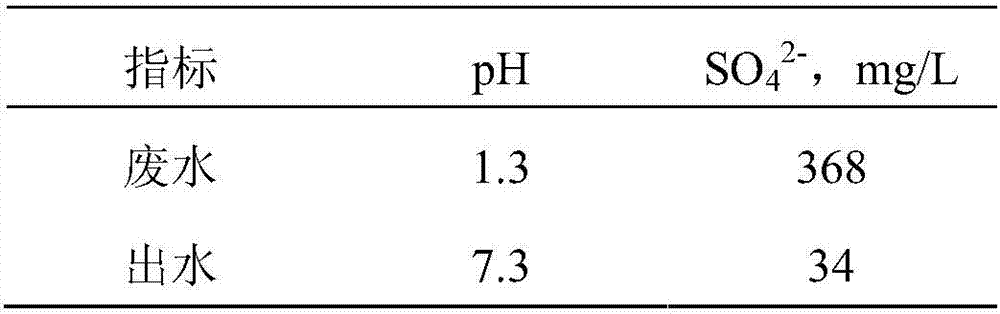

[0047] The sulfate-containing wastewater is wastewater from an electroplating plant. The water quality is shown in Table 3:

[0048] Table 3 Electroplating wastewater and water quality after treatment

[0049]

[0050] Adjust the pH of the wastewater to 5.5, to 25cm 2 The square lead plate is the anode, the metal titanium plate of the same size is used as the cathode, and the voltage is 5V and the current density is 0.6A / cm under the condition that the anode and the cathode are directly opposite and the pole distance is kept 20cm. 2 Under electrolysis for 30 minutes, adjust the pH to 7.3, and the effluent quality reaches the discharge standard, see Table 3. SO in wastewater 4 2- The removal rate is 90.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com