Preparation method of high-performance Cr3+ and Nd3+ compositely doped GSGG laser ceramic

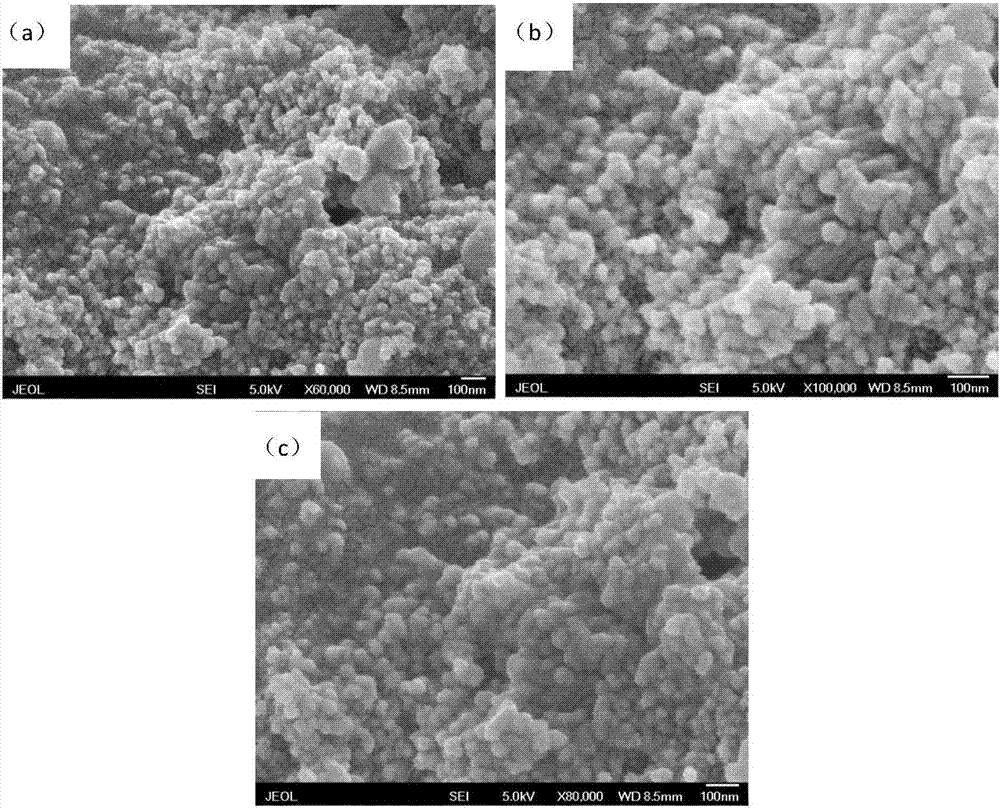

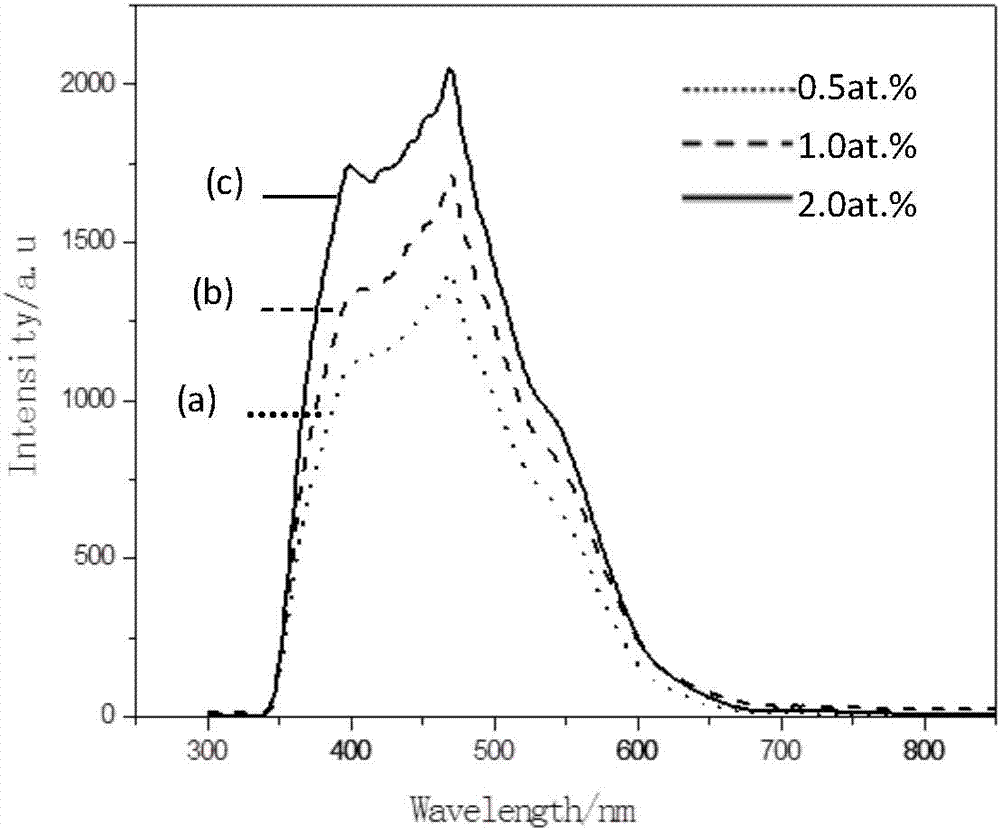

A technology of laser ceramics and compound doping, which is applied in the preparation of Cr3+, Nd3+: GSGG nano-powders, Cr3+, Nd3+ compound doped GSGG laser ceramics and its preparation field by one-step co-precipitation method, which can solve the problem of poor sintering activity and powder particles Large size, wide particle size distribution, etc., to achieve the effect of high doping concentration, dense structure, and wide fluorescence spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) High-purity Gd with a weight ratio content of 99.99% 2 o 3 、Sc 2 o 3 and Ga 2 o 3 The powder is dissolved in dilute nitric acid according to the molar ratio of 3:2:3, Cr 2 o 3 、Nd 2 o 3 The powder was dissolved in dilute nitric acid according to 0at.% and 0at.%, respectively, and then mixed into a uniform 5mol / L nitrate solution.

[0018] 2) Using ammonia water as a precipitating agent, inject it into the above mixed solution in one step, and at the same time fully stir to adjust the pH of the solution to 8-10, and then age at room temperature for 8 hours.

[0019] 3) After aging, filter and wash the precipitate with deionized water and absolute ethanol, dry the washed precipitate in a drying oven at 100°C for 24 hours, and then grind the dried powder and calcinate at 1000°C in an air atmosphere 4h.

[0020] 4) The calcined powder is firstly formed by dry pressing at a pressure of 200 MPa, and then cold isostatically pressed at a pressure of 200 MPa.

[00...

Embodiment 2

[0023] Adopt the same process of embodiment 1, just make Cr 2 o 3 、Nd 2 o 3 The powder is dissolved in dilute nitric acid according to 0 at.% and 1 at.% respectively, and the rest of the conditions are the same as in Example 1, and laser ceramics can also be obtained.

Embodiment 3

[0025] Adopt the same process of embodiment 1, just make Cr 2 o 3 、Nd 2 o 3 The powder was dissolved in dilute nitric acid at 0.5 at.% and 1 at.% respectively, and the rest of the conditions were the same as in Example 1, and laser ceramics could also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com