Carbon fiber reinforced alumina ceramic composite material and preparation method thereof

A technology of alumina ceramics and composite materials, applied in the field of materials, can solve the problems of catastrophic decline in material properties, easy oxidation of carbon fibers, expensive silicon carbide fibers, etc., to reduce equipment requirements and energy consumption, small thermal expansion coefficient, and cross-section infiltration. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

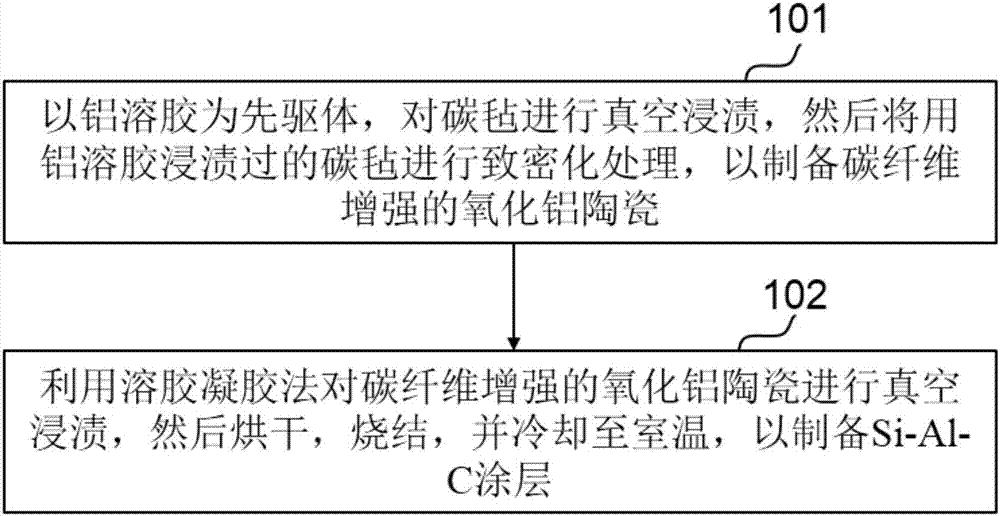

[0024] Such as figure 1 As shown, a method for preparing a carbon fiber reinforced alumina ceramic composite material according to an embodiment of the present invention includes the following steps:

[0025] S101: Using aluminum sol as a precursor, vacuum impregnate carbon felt, and then densify the carbon felt impregnated with aluminum sol to prepare carbon fiber-reinforced alumina ceramics. Specifically, first use aluminum nitrate sol as a precursor to vacuum impregnate the carbon felt after ultrasonic cleaning, and then dry it. After drying, put it into a high-temperature furnace for vacuum sintering, keep vacuum cooling to room temperature, and complete a densification process. Then repeat the above steps 10 to 12 times until the weight of the sample no longer increases, so as to obtain carbon fiber reinforced alumina composite ceramics. As the reinforcement of alumina ceramics, carbon fiber has high specific strength and specific modulus, no creep, good fatigue resistan...

Embodiment 1

[0030] Embodiment 1 is a specific preparation process of a carbon fiber reinforced alumina ceramic composite material, which uses alumina as a matrix, polyacrylonitrile-based carbon felt as a reinforcement, and a Si-Al-C oxidation-resistant coating on the surface, including The following specific steps:

[0031]Take 100g of aluminum nitrate, add deionized water, heat and stir in a water bath, wherein the temperature of the water bath is set at 85°C, and continue to stir in the water bath for 30-40 minutes to hydrolyze the aluminum nitrate as much as possible. Then add 12.5% ammonia water in batches until the pH of the liquid is 3.5-5. While further promoting hydrolysis, the properties of the sol are stabilized and the size of the colloidal particles is adjusted. Then evaporate the liquid, so that the concentration of aluminum ions is 6mol / L, and the viscosity is about 6mPa·S. This concentration and viscosity can increase the impregnation efficiency as much as possible while ...

Embodiment 2

[0038] Embodiment 2 is a specific preparation process of a carbon fiber reinforced alumina ceramic composite material, which uses alumina as a matrix, polyacrylonitrile-based carbon felt as a reinforcement, and a Si-Al-C oxidation-resistant coating on the surface, including The following specific steps:

[0039] Take 100g of aluminum nitrate, add deionized water, heat and stir in a water bath, wherein the temperature of the water bath is set at 90°C, and continue to stir in the water bath for 30-40 minutes to hydrolyze the aluminum nitrate as much as possible. Then add 15% ammonia water in batches until the pH of the liquid is 3.5-5, further promote the hydrolysis, stabilize the properties of the sol, and adjust the size of the colloidal particles. Then evaporate the liquid so that the concentration of aluminum ions is 5mol / L and the viscosity is about 6mPa·S. This concentration and viscosity can increase the impregnation efficiency as much as possible while ensuring the impre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com