Growing culture medium for ecological remediation and preparation method thereof

A cultivation substrate, ecological restoration technology, applied in the directions of planting substrate, botanical equipment and methods, cultivation, etc., can solve the problems of unsustainable, slow growth of plants, and narrow application range, achieve self-ecological cycle, improve plant The effect of growing environment and improving the quality of seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

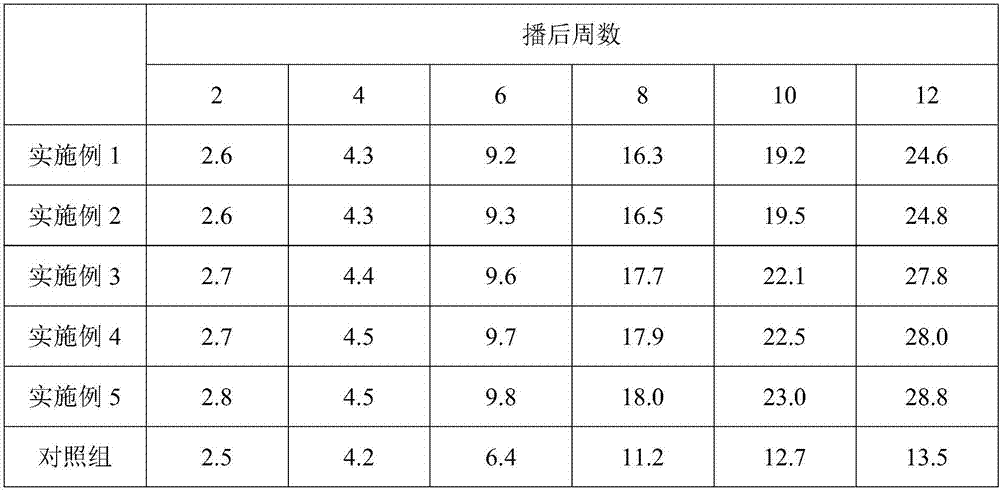

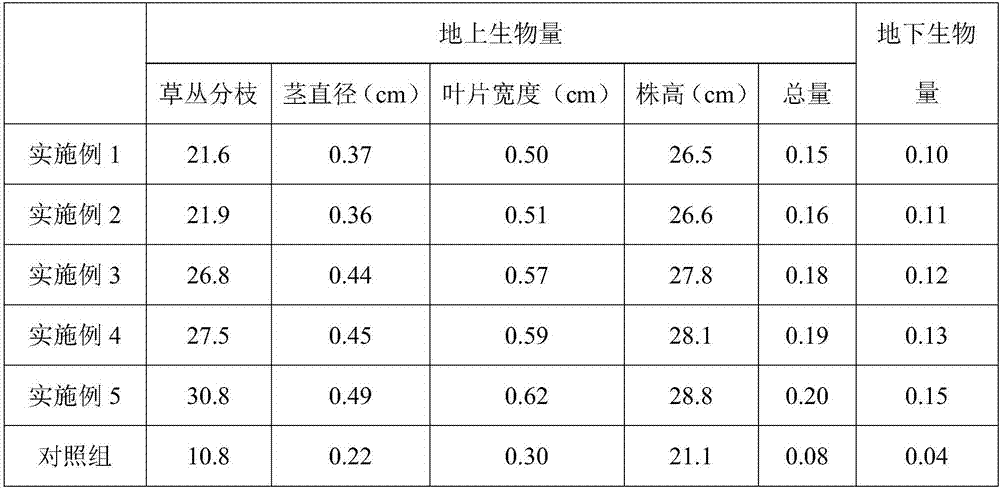

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a growth and cultivation substrate for ecological restoration is composed of the following raw materials in parts by weight: lutein ester 5kg, lignocellulose 11kg, alginate 7kg, straw powder 28kg, tartaric acid 15kg, flower acid Moss 20kg, propyl acetate 1kg. Grind the sorrel moss into powder, pass through a 60-mesh sieve to obtain the sour moss powder, and mix the sour moss powder with half the weight of tartaric acid and 7 times the mass of the sour moss powder with deionized Mixed with water, heated to 63°C, and kept at this temperature for 55min, and then subjected to ultrasonic treatment, the ultrasonic treatment time was 48min, the ultrasonic power was 500W, and the ultrasonic temperature was 70°C to obtain a mixture A. At a stirring speed of 100r / min, add lignocellulose and propyl acetate to mixture A, heat to 88°C, and keep at this temperature for 20min, then perform ultrasonic treatment, the ultrasonic treatment time ...

Embodiment 2

[0023] In the embodiment of the present invention, a growth and cultivation substrate for ecological restoration is composed of the following raw materials: 12 kg of lutein ester, 19 kg of lignocellulose, 15 kg of alginate, 36 kg of straw powder, 25 kg of tartaric acid, 30 kg of moss moss, acetic acid Propyl ester 5kg. Grind the sorrel moss into powder, pass through a 100-mesh sieve to obtain the sour moss powder, mix the sour moss powder with half the weight of tartaric acid and 9 times the mass of the sour moss powder with deionized Mixed with water, heated to 65°C, and maintained at this temperature for 60min, and then subjected to ultrasonic treatment, the ultrasonic treatment time was 55min, the ultrasonic power was 500W, and the ultrasonic temperature was 75°C to obtain a mixture A. At a stirring speed of 120r / min, add lignocellulose and propyl acetate into mixture A, heat to 92°C, and keep at this temperature for 25min, then perform ultrasonic treatment, the ultrasonic ...

Embodiment 3

[0025] In the embodiment of the present invention, a growth and cultivation substrate for ecological restoration is composed of the following raw materials: 7 kg of lutein ester, 13 kg of lignocellulose, 9 kg of alginate, 30 kg of straw powder, 18 kg of tartaric acid, 22 kg of moss moss, acetic acid Propyl ester 2kg. Grind the sorrel moss into powder, and pass through a 80-mesh sieve to obtain the sour moss powder. At a stirring speed of 110 r / min, mix the sour moss powder with half the weight of tartaric acid and 8 times the mass of the sour moss powder. Mix with water, heat to 64°C, and keep at this temperature for 58min, and then perform ultrasonic treatment, the ultrasonic treatment time is 50min, the ultrasonic power is 500W, and the ultrasonic temperature is 72°C to obtain the mixture A. At a stirring speed of 110r / min, add lignocellulose and propyl acetate to mixture A, heat to 90°C, and keep at this temperature for 22min, then perform ultrasonic treatment, the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com