Glucosamine sulfate product and preparation method thereof

A technology of glucosamine sulfate and glucosamine hydrochloride, applied in the preparation of amino sugar and sugar derivatives, chemical instruments and methods, etc., can solve the problems of poor pH control, uneven dispersion, poor solubility, etc., and achieve good physical Morphological, Yield-enhancing, Ease of Crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

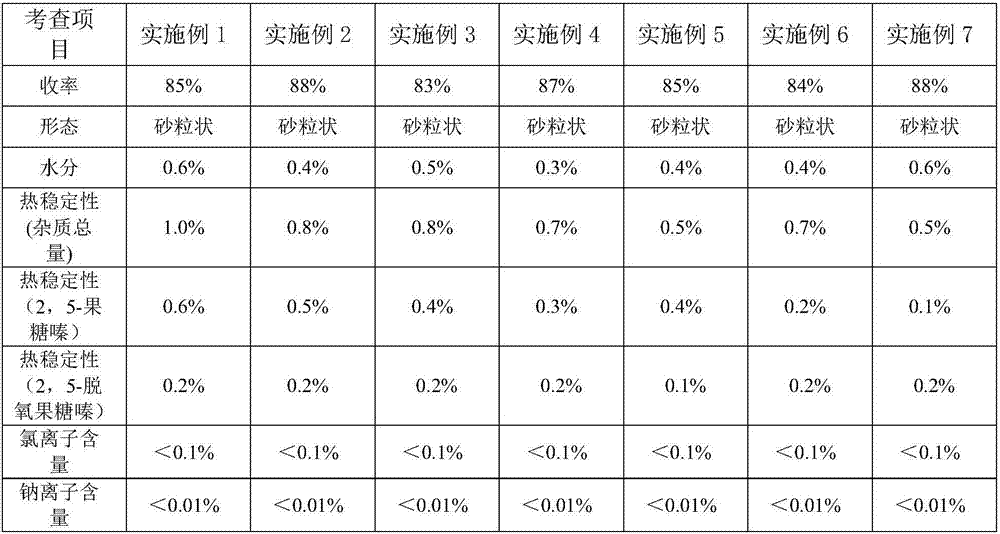

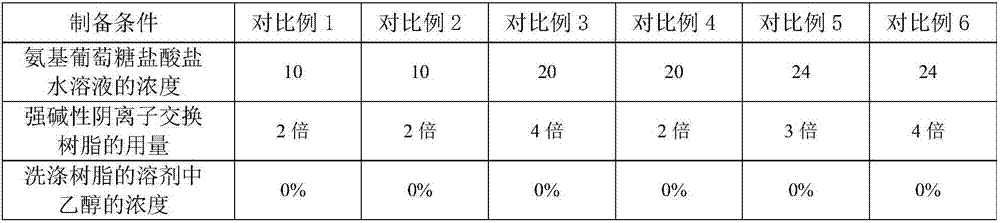

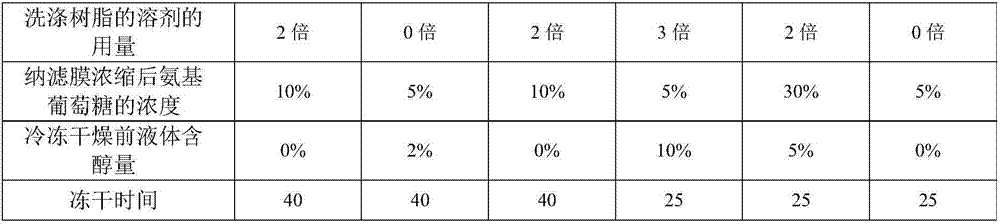

Examples

Embodiment 1

[0041] Follow the steps below to prepare high-purity glucosamine sulfate

[0042] 1. Soak the strongly basic anion exchange resin with 0.8 hydrochloric acid for 2.5 hours, wash with deionized water until neutral, then soak with 0.8 sodium hydroxide for 2.5 hours, and then wash with deionized water until neutral.

[0043] 2. Configure glucosamine hydrochloride into a 15% aqueous solution, use pre-washed strong basic anion exchange resin to remove chloride ions in the aqueous solution, repeat 2 times, use glucosamine sulfate hydrochloride each time Strongly basic anion exchange resin with light on.

[0044] 3. Wash the anion exchange resin twice, the solvent used is purified water.

[0045] 4. Collect the glucosamine solution, concentrate it with a nanofiltration membrane, the molecular weight cut-off is 100-150D, concentrate it to 10%, add sulfuric acid to react.

[0046] 5. Freeze-drying, first lower the temperature of the product to -20°C, after forming frozen crystals, the...

Embodiment 2

[0048] Follow the steps below to prepare high-purity glucosamine sulfate

[0049] 1. Soak the strongly basic anion exchange resin in 1.2M hydrochloric acid for 1.5 hours, wash it with deionized water until it is neutral, then soak it with 1.2M sodium hydroxide for 1.5 hours, then wash it with deionized water until it is neutral.

[0050] 2. Configure glucosamine hydrochloride into a 20% aqueous solution, use pre-washed strong basic anion exchange resin to remove chloride ions in the aqueous solution, repeat 3 times, use glucosamine sulfate hydrochloride each time Strongly basic anion exchange resin with light on.

[0051] 3. Washing the anion exchange resin for 3 times, the solvent used is 2% ethanol solution.

[0052] 4. Collect the glucosamine solution, use nanofiltration membrane to concentrate, the molecular weight cut off is 100-150D, concentrate to 20%, add sulfuric acid to react.

[0053] 5. Freeze-drying, first lower the temperature of the product to -5°C, after the ...

Embodiment 3

[0055] Follow the steps below to prepare high-purity glucosamine sulfate

[0056] 1. Soak the strongly basic anion exchange resin in 1M hydrochloric acid for 2 hours, wash it with deionized water until it is neutral, then soak it with 1M sodium hydroxide for 2 hours, and then wash it with deionized water until it is neutral.

[0057] 2. Configure glucosamine hydrochloride into a 20% aqueous solution, use pre-washed strong basic anion exchange resin to remove chloride ions in the aqueous solution, repeat 4 times, use glucosamine sulfate hydrochloride each time Strongly basic anion exchange resin with light on.

[0058] 3. Wash the anion exchange resin 4 times, the solvent used is purified water or 10% ethanol solution.

[0059] 4. Collect the glucosamine solution, use nanofiltration membrane to concentrate, the molecular weight cut off is 100-150D, concentrate to 25%, add sulfuric acid to react.

[0060] 5. Freeze-drying, first lower the temperature of the product to -10°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com