Production method of stock solution-colored blue nylon 6 fiber

A technology of dope coloring and production method, which is applied in the direction of fiber treatment, spinning solution degassing, feeding solution to spinneret, etc., which can solve the problems of short service life and meet the requirements of wool, uniform color and high color fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of production method of dope dyed blue nylon 6 fiber, comprises the following steps:

[0032] 2.0 parts of blue masterbatch and 98.0 parts of polyamide 6 semi-gloss chips are fully melted and then mixed and extruded. The blue masterbatch is prepared from the following raw materials in parts by weight: 30 parts of blue pigment powder, 10 parts of dispersant 60 parts and 60 parts of polyamide 6 slices, the melting temperature is 261 °C, the melt is accurately metered by the metering pump, enters the spinning assembly, and is spun out to form filaments. The diameter of the spinning cylindrical filter is 15 μm, and the spinning The initial pressure of the assembly is 150bar, the aspect ratio of the spinneret holes on the spinneret plate is 2.5, and then the monomer is sucked, cooled by side blowing, oiled in clusters, network intertwined, and then wound and formed to obtain the coloring of the dope Blue nylon 6 fiber;

[0033] The stock solution dyed blue nylon 6 fi...

Embodiment 2

[0036] A kind of production method of dope dyed blue nylon 6 fiber, comprises the following steps:

[0037] 3.6 parts of blue masterbatch and 96.4 parts of polyamide 6 semi-gloss chips are fully melted and then mixed and extruded. The blue masterbatch includes the following raw materials in parts by weight: 25 parts of blue pigment powder, 5 parts of dispersant 70 parts and 70 parts of polyamide 6 slices, the melting temperature is 260 ° C, the melt is accurately metered by the metering pump, enters the spinning assembly, and is spun out to form filaments. The diameter of the spinning cylindrical filter is 30 μm, and the spinning The initial pressure of the component is 165bar, the aspect ratio of the spinneret hole on the spinneret is 4, and then the monomer is sucked, cooled by side blowing, oiled in clusters, network intertwined, and then wound and formed to obtain the coloring of the dope Blue nylon 6 fiber;

[0038] The stock solution dyed blue nylon 6 fiber (85D / 24F) pr...

Embodiment 3

[0041] A kind of production method of dope dyed blue nylon 6 fiber, comprises the following steps:

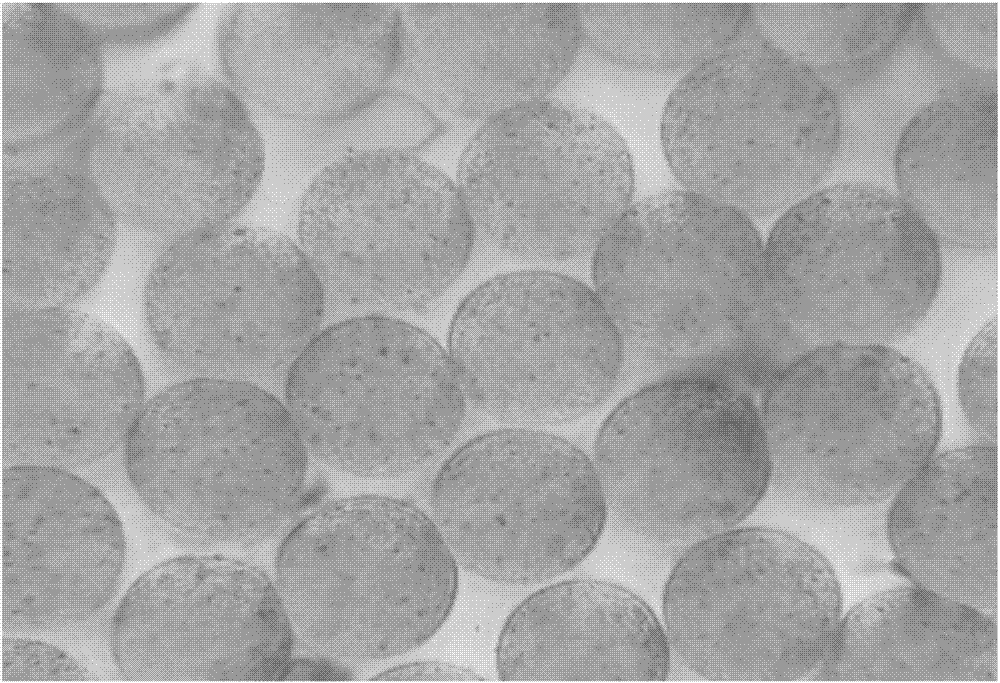

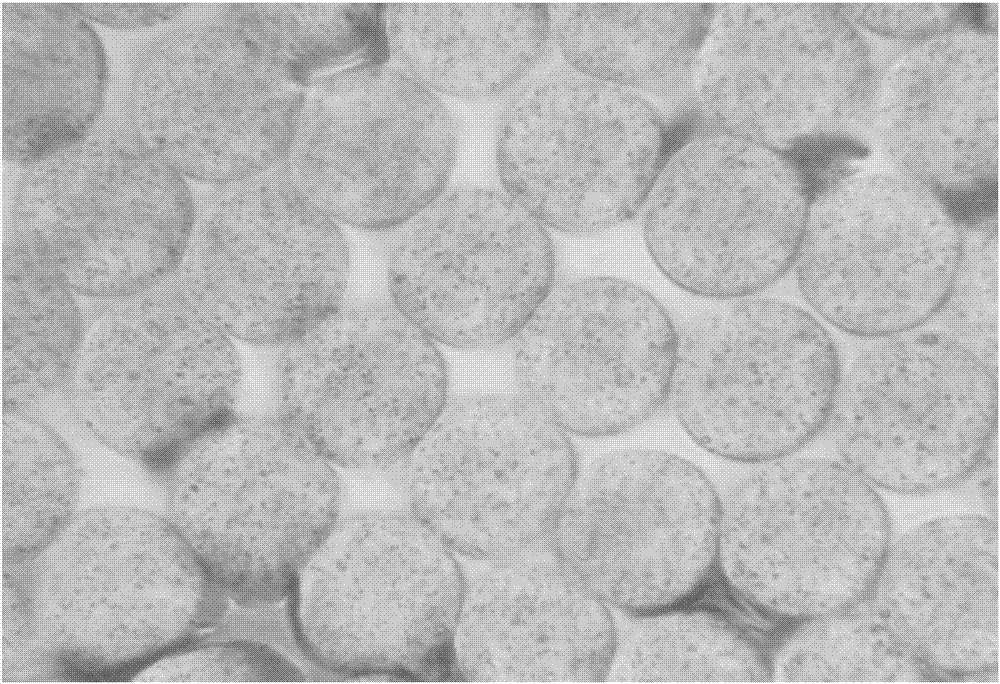

[0042] 3.0 parts of blue masterbatch and 97.0 parts of polyamide 6 semi-gloss chips are fully melted and then mixed and extruded. The blue masterbatch is prepared from the following raw materials in parts by weight: 28 parts of blue pigment powder, 8 parts of dispersant 64 parts and 64 parts of polyamide 6 slices, the melting temperature is 261 °C, the melt is accurately metered by the metering pump, enters the spinning assembly, and is spun out to form filaments. The diameter of the spinning cylindrical filter is 15 μm, and the spinning The initial pressure of the assembly is 135bar, the aspect ratio of the spinneret holes on the spinneret plate is 3.5, and then through monomer suction, side blowing cooling, cluster oiling, network intertwining, and then winding to obtain the coloring of the dope Blue nylon 6 fiber, its cross-sectional view is shown in figure 1 ;

[0043] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com