Zinc acrylate and silicon copolymerized antifouling resin and preparation method thereof

A technology of zinc acrylate and antifouling resin, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., which can solve the problems of poor initial adhesion inhibition effect and high cost, and achieve the phenomenon that it is not easy to gel , Viscosity does not change much, and the effect of stabilizing the hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 170.8g of propylene glycol methyl ether and 81.4g of zinc oxide into a four-necked flask equipped with a stirrer, condenser, and thermometer, raise the temperature to 75-80°C, add 86.1g of methyl methacrylate, 144.2g of isocyanate dropwise within 3 hours The mixture of caprylic acid and 10.0g deionized water was kept in a reflux state during the dropwise addition. After the dropwise addition, keep the temperature for 2 hours, then add 95.0 g of propylene glycol methyl ether to complete the reaction, and then obtain a transparent zinc acrylate monomer solution. The solid content of the above solution was measured to be 50%.

Embodiment 2

[0030] Add 15.0 g of propylene glycol methyl ether and 57.0 g of xylene mixed solvent into a four-necked flask equipped with a stirrer, condenser, thermometer, and nitrogen conduit. ℃, then weigh the mixture of 10.0g methyl methacrylate, 52.0g ethyl acrylate, 31.0g triisopropylsilyl acrylate, 14.0g zinc acrylate monomer and 1.5g azobisisobutyronitrile, stir completely After dissolving, drop it into the flask at a constant speed within 3 hours through a constant pressure dropping funnel, and then add a mixed solution of 0.5g benzoyl peroxide and 10g xylene dropwise within half an hour after the dropwise addition, and finish after 2.5 hours of heat preservation Reaction, that is, a colorless transparent acrylate zinc / silicon copolymer resin is obtained.

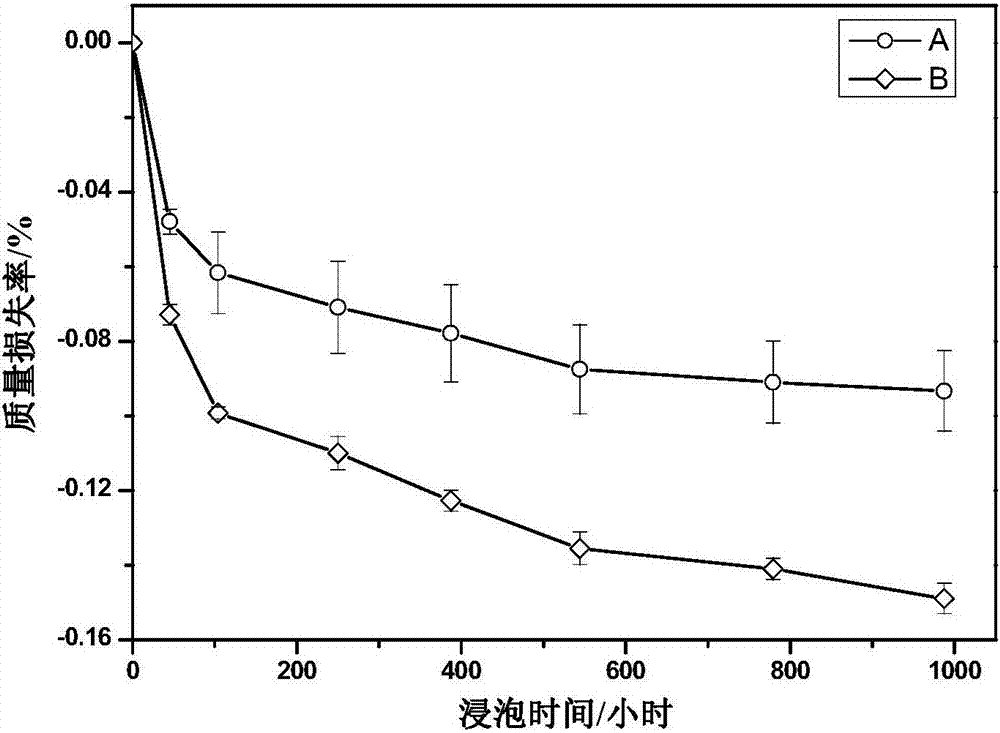

[0031] The sample prepared in this embodiment contains 45.9% non-volatile matter, and its viscosity is 121.5mPa·s. Through gel permeation chromatography test analysis, the weight molecular weight is 7.7×10 3 g / mol, the acid va...

Embodiment 3

[0033] Add 15.0 g of propylene glycol methyl ether and 57.0 g of xylene mixed solvent into a four-necked flask equipped with a stirrer, condenser, thermometer, and nitrogen conduit. ℃, then weigh the mixture of 10.0g methyl methacrylate, 52.0g ethyl acrylate, 25.0g triisopropylsilyl acrylate, 26.0g zinc acrylate monomer and 1.5g azobisisobutyronitrile, stir completely After dissolving, drop it into the flask at a constant speed within 3 hours through a constant pressure dropping funnel, and then add a mixed solution of 0.5g benzoyl peroxide and 10g xylene dropwise within half an hour after the dropwise addition, and finish after 2.5 hours of heat preservation Reaction, that is, a colorless transparent acrylate zinc / silicon copolymer resin is obtained.

[0034] The sample prepared in this embodiment contains 43.9% non-volatile matter, and its viscosity is 286.2mPa·s. Through gel permeation chromatography test analysis, the weight molecular weight is 8.2×10 3 g / mol, the acid va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com